Goods Inspection & Apply for PVoC -- IMEXsourcing Professional Services Ensure Export Compliance

IMEX Sourcing Goods Inspection Record in Qingdao Free Trade Zone: Professional Service Guarantees Export Compliance

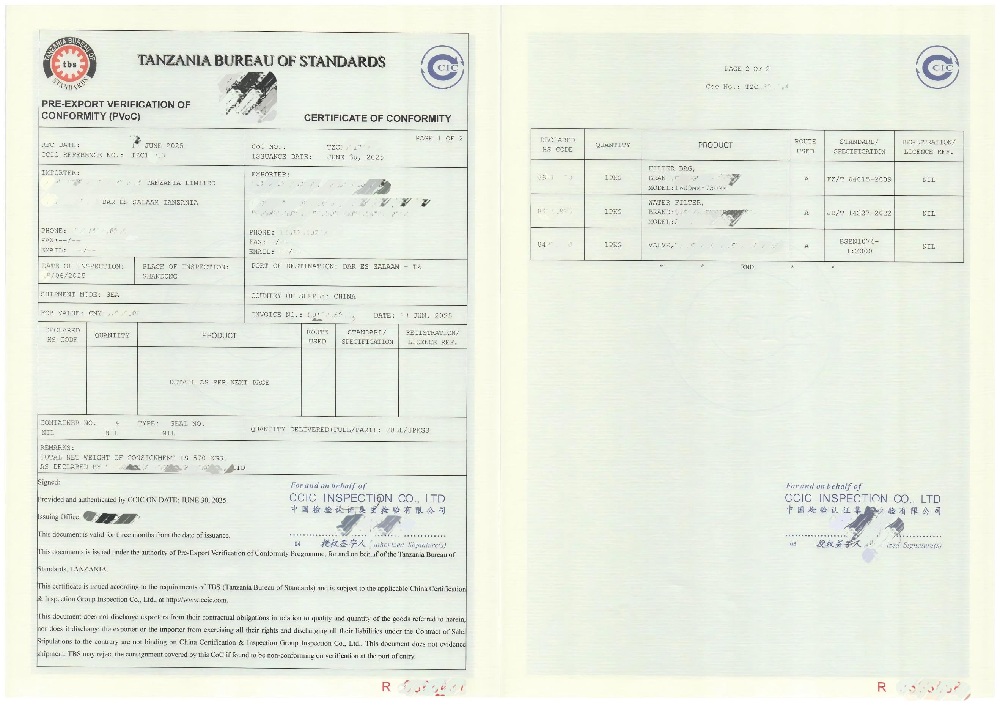

On June 30, the IMEX Sourcing inspection team was entrusted by the customer to go to the Qingdao Free Trade Zone LCL warehouse to provide full-process inspection services for a batch of export products of the customer before shipment. This task covers key links such as product inspection, quality verification, photo archiving, certification labeling, and PVoC certificate (pre-shipment conformity verification) application to ensure that the goods comply with the regulations of the destination country and help customers pass customs smoothly

1. Inspection background and customer needs

The customer plans to export a batch of industrial parts to a country in Africa. The customs of that country requires all imported goods to provide PVoC certificates to prove that the products meet local technical standards and safety regulations. Since the customer's factory is located in an inland area, the goods must first be collected in the Qingdao Free Trade Zone LCL warehouse before being shipped to the destination port. Therefore, the customer entrusted IMEX Sourcing to complete the following work before the goods were shipped:

Product inspection: Check whether the quantity, specifications, appearance and function of the goods meet the order requirements;

Quality sampling: Sampling test according to international standards (such as ISO/ASTM);

Document review: Check the integrity and consistency of documents such as packing list, invoice, quality inspection report, etc.;

Certification labeling: Affix the anti-counterfeiting label and certification mark specified by the customer to qualified products;

PVoC application: Organize the test report and inspection record and submit it to the certification body for review.

II. Inspection process execution details

1. On-site inspection at the warehouse

At 8 o'clock in the morning, the IMEX team arrived at the Qingdao Free Trade Zone warehouse. The goods in the warehouse have been sorted and preliminarily packaged according to the customer's requirements. The inspector first checked whether the goods mark, batch number and order information were consistent, and then randomly unpacked and inspected according to the AQL 2.5 standard (international general inspection sampling standard). Key inspection contents include:

Appearance defects: such as scratches, rust, deformation, etc.;

Functional test: Randomly select 5% of samples for assembly test to ensure that the component interfaces match and there is no jamming;

Packaging compliance: Confirm that the inner packaging is adequately filled with shockproof materials, and the printed information on the outer box is clear and complies with the labeling regulations of the destination country.

2. Problem discovery and communication

During the inspection process, the team found that the batch labels of some product boxes were blurred, which could easily lead to difficulties in customs inspection. Immediately contacted the customer's quality department, and after confirmation, asked the warehouse to replace the label and reprint it. At the same time, it was found that a box of goods had a slight bump. After communicating with the customer, the team assisted the warehouse in repackaging and reinforcing the goods to ensure the transportation safety of all goods and guarantee the shipping standards.

3. Photo and document record

IMEX inspectors took photos of each batch of goods from multiple angles for archiving, including:

Overall goods stacking;

Product details (such as nameplates, specifications);

Close-up of packaging logos and certification labels. The photos are uploaded to the IMEX cloud system for customers to view in real time and serve as auxiliary evidence for PVoC application.

4. Labeling and certification preparation

According to the label template provided by the customer, the team affixes a QR code anti-counterfeiting label and CE mark to each product (some parts must comply with EU directives). Then, the inspection report, test certificate, packing list and other documents are sorted out and submitted to the cooperative certification agency to start the expedited application process for the PVoC certificate.

III. The key role of PVoC certificate

PVoC (pre-shipment conformity verification) is a customs clearance document required by many countries in Africa and the Middle East to prevent unqualified goods from entering the market. The IMEX team pays special attention to the following in the inspection:

Consistency between products and test reports: Ensure that the actual goods fully match the declared model and parameters;

Document integrity: Assist customers to supplement missing supplier declarations or test data;

Quick response: Through long-term certification channels, the original 3 working days process is compressed to 1 day to avoid delays in shipping.

IV. Customer Feedback and Project Summary

In the evening of the same day, the customer received the detailed inspection report and PVoC pre-audit approval notice submitted by IMEX, and highly recognized the team's efficient execution and problem-solving capabilities. This inspection not only ensured the smooth shipment of the goods, but also laid a foundation of trust for the customer's subsequent long-term cooperation.

Conclusion

IMEX Sourcing has always adhered to the concept of "details determine success or failure" and helped customers avoid trade risks through professional inspection services. From on-site inspection to certification support, we are committed to becoming a reliable quality gatekeeper in the global supply chain.