How to Purchase Mining Grinding Materials, Steel Balls, and Ball Mill Liners from China

IntroductionThe mining industry requires highly durable and efficient grinding materials to maximize the performance of their milling processes. Key components such as grinding cast steel balls, forged steel balls, and mill liners are crucial for optimizing productivity and extending the lifespan of mining equipment. In this article, we will explore the details of these essential materials, their specifications, industry hotspots in China, leading suppliers, and key considerations when selecting the right products for your mining operations.

I. Introduction to Grinding Steel Balls

Grinding steel balls are core grinding media for ball mills in mining, building materials, power, and other industries. Their manufacturing principles vary by process—cast steel balls and forged steel balls are the most widely used types today. Below is a detailed breakdown of their core principles, key steps, and performance correlations.

I. Cast Steel Balls: "Liquid Forming + Hardening Strengthening"

Cast steel balls are formed by pouring molten steel into molds and then optimizing performance through heat treatment. They are suitable for grinding scenarios with medium-to-low impact loads (e.g., cement production, mineral flotation).

Core Principle:

Leveraging the fluidity of liquid metal to form spherical blanks via molds, then enhancing hardness, wear resistance, and toughness through **chemical composition control** and **heat treatment (quenching + tempering).

Key Steps & Principles:

- 1. Raw Material Melting & Composition Design

Using scrap steel, pig iron, and alloys (chromium, manganese, etc.) as raw materials, the composition is adjusted based on performance requirements (e.g., high-chromium balls contain 10%-15% chromium). The mixture is melted in a medium-frequency furnace at 1500-1600°C to remove impurities, resulting in uniform molten steel.

Principle: Alloy elements form wear-resistant carbides (chromium, molybdenum) or improve toughness (manganese, nickel).

- 2. Casting & Forming

Molten steel is poured into sand molds, metal molds, or centrifugal molds. After cooling and solidification, the mold is removed to obtain spherical blanks.

Principle: Liquid metal takes shape according to the mold. Faster cooling speeds lead to finer grains and higher blank strength.

- 3. Heat Treatment Strengthening

Quenching: Heated to 850-1000°C, then cooled in water or oil. Austenite transforms into hard and brittle martensite, achieving a hardness of HRC55-65.

Tempering: Slow cooling at 200-400°C to reduce internal stress, balancing hardness and toughness.

Principle: Optimizing microstructure through solid-state phase transformation, ensuring both wear resistance and fracture resistance.

- 4. Post-Processing

Remove risers, grind burrs, and conduct size screening and hardness testing before finalizing the product.

II. Forged Steel Balls: "Solid Plastic Deformation + Microstructure Optimization"

Forged steel balls are formed by applying external force to solid steel billets for plastic deformation. They are ideal for heavy-duty grinding scenarios with high impact loads (e.g., rough grinding of metal ores, pellet grinding).

Core Principle

Utilizing metal plasticity, forging (hammer forging, roll forging, etc.) induces plastic deformation of steel billets at high temperatures to refine grains, eliminate internal defects, and further enhance mechanical properties through heat treatment.

Key Steps & Principles

- 1. Raw Material Selection & Billet Preparation

High-quality round steel (e.g., 45# steel) is cut into fixed-length cylindrical billets, with lengths slightly larger than the steel ball diameter.

Principle: High-quality steel has uniform microstructure and few impurities, providing a good plastic foundation for forging.

- 2. Heating & Softening

Billets are heated to the austenitizing temperature range (800-1200°C), significantly improving steel plasticity and reducing resistance to facilitate plastic deformation.

Principle: High temperatures enhance metal atom activity and weaken grain boundaries, making billets easier to forge without cracking.

- 3. Forging & Forming

Hammer forging: Steel billets are repeatedly struck by air hammers or hydraulic hammers, forming spherical shapes under mold constraints.

Roll forging: Arc rollers rotate to extrude billets for continuous forming (suitable for mass production).

Principle: External force breaks and rearranges grains into dense fibrous structures, eliminating defects like pores and improving density and strength.

- 4. Heat Treatment

Processes vary by steel type: Low-carbon steel undergoes normalizing to refine grains; medium-high carbon steel undergoes quenching (to form martensite) followed by tempering to balance performance.

Principle: Forging-refined grains enhance base strength, while heat treatment further optimizes microstructure, achieving HRC50-60 hardness with better toughness than cast steel balls of the same hardness.

- 5. Surface Treatment & Inspection

Shot blasting removes oxide scales, followed by inspections for dimensional accuracy, roundness, and internal defects (e.g., ultrasonic testing).

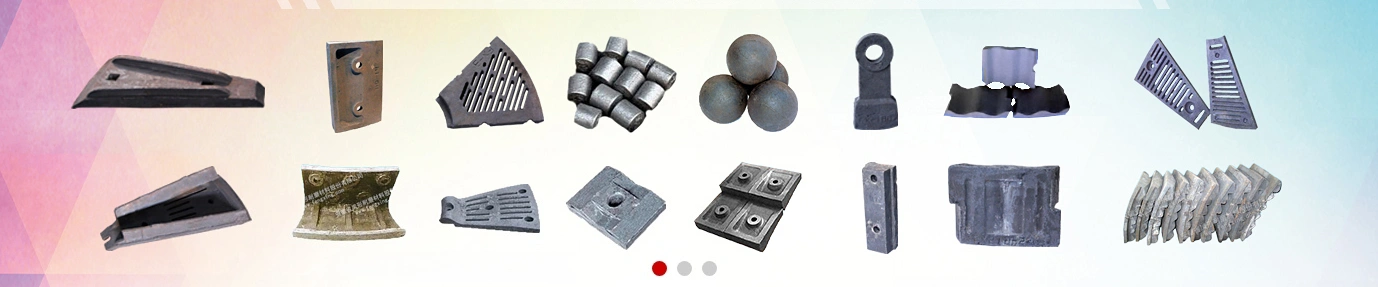

III.Mill Liners:

These are metal or composite plates that are installed inside the ball mill to protect the interior surface of the mill from wear and tear, while also optimizing the grinding action.

Overview: China’s Edge in Steel Ball Production

Cast steel balls are energy-intensive, requiring substantial electricity. China’s stable and low-cost power supply, coupled with a continuous supply of scrap iron, has created unique advantages in steel ball manufacturing. Today, China stands as the world’s largest producer of steel balls.

II.Specifications and Parameters

Each type of grinding material comes with its own set of specifications and parameters, which can affect performance and efficiency in the milling process. Let’s look at the common parameters for each material:

Grinding Cast Steel Balls

Material Composition: Typically made from high carbon steel, cast steel balls contain alloys such as chromium, manganese, and molybdenum to enhance hardness and wear resistance.

Diameter: The diameter of cast steel balls generally ranges from 20mm to 150mm, depending on the size of the mill.

Hardness: Cast steel balls typically have a hardness of HRC 45-55. The higher the hardness, the longer the lifespan of the balls.

Density: Around 7.8 g/cm³, ensuring optimal impact resistance and effective grinding.

Forged Steel Balls

Material Composition: Made from carbon steel or alloy steel, forged steel balls have higher density and greater uniformity in their hardness compared to cast balls.

Diameter: Forged balls typically range from 20mm to 150mm in diameter, with larger balls used for coarse grinding.

Hardness: Generally, forged steel balls have a hardness range of HRC 55-65.

Impact Toughness: Due to their manufacturing process, forged steel balls exhibit higher toughness and resistance to fracture.

Mill Liners

Material Composition: Mill liners are typically made from high-chromium alloy, manganese steel, or rubber composites. The choice of material depends on the type of ore being processed and the wear conditions inside the mill.

Thickness: Mill liners can vary in thickness from 30mm to 100mm or more, depending on the specific needs of the mill.

Shape: Mill liners come in various designs, such as wave, ribbed, and lifter configurations, to improve the milling efficiency by creating a better grinding environment.

III. Key Industry Hotspots in China

China is the global leader in the production and export of mining grinding materials. The country hosts a number of major production hubs, especially in regions that are rich in minerals. Here are the key areas where these materials are produced:

Shandong Province: Known for its large-scale steel production and mining equipment manufacturing, Shandong is home to many companies specializing in forging and casting steel balls and mill liners. Cities like Zibo and Weifang are major centers for the production of these materials.

Hebei Province: As a steel manufacturing powerhouse, Hebei is a key region for producing high-quality grinding materials. The province houses several companies that export forged and cast steel balls worldwide.

Jiangsu Province: Jiangsu is another significant region in China for the production of mining equipment, including grinding materials. Companies in cities like Nanjing and Wuxi are known for their high standards in producing mill liners and grinding balls.

Anhui Province: Anhui FengXing New Material Technology Co., Ltd, China’s largest steel ball manufacturer, is located in Ningguo City, Anhui Province.

IV. Leading Companies in the Mining Grinding Materials Industry

Several Chinese companies are well-known for producing and supplying high-quality grinding materials. Here are some of the industry leaders:

Anhui FengXing New Material Technology Co., Ltd.: Headquartered in Ningguo, Anhui, it is a listed company in China and one of the leading manufacturers in the steel ball industry.

Shandong Huamin Steel Ball Co., Ltd.: Located in Shandong Province, its main products include mining wear-resistant forged steel balls, heat-treated steel grinding rods, and cast iron balls, with an annual production capacity of 150,000 tons.

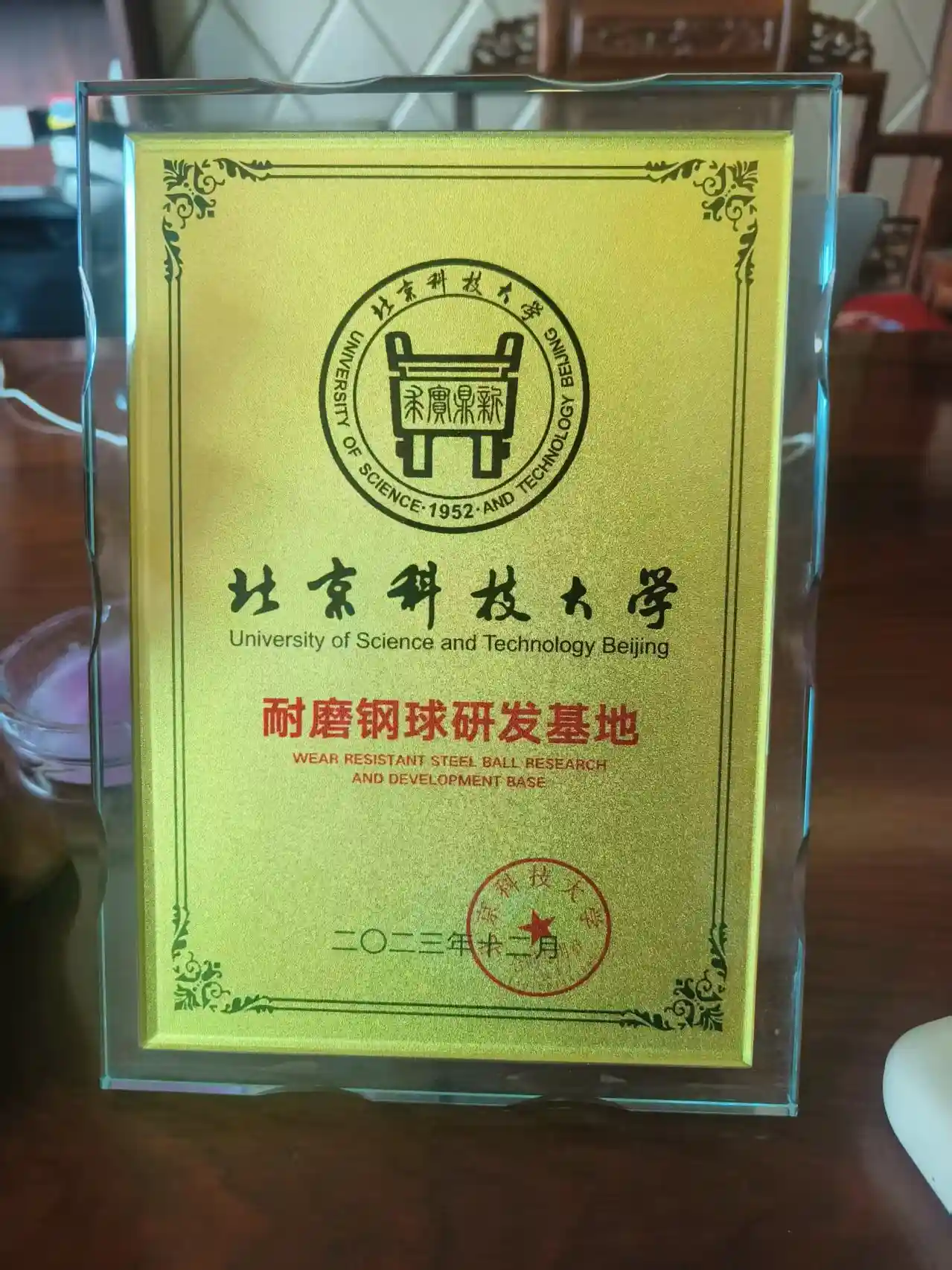

Qingzhou Taihong Special Casting Steel Co., Ltd.: Founded in 1978, the company boasts advanced technology and serves as a wear-resistant steel ball R&D base of the University of Science and Technology Beijing. It provides cost-effective and high-quality products for clients in multiple mining sectors and holds a high market share in South America and Africa.

Qingzhou Huahong Grinding Ball Co., Ltd. : As a well-known manufacturer in Shandong Province, the company owns fully automatic production lines and innovative patented technologies, and has long-term cooperative relationships with many famous gold mines in China.

Weifang Durable Mining Equipment Co., Ltd.: Located in Weifang, Shandong, it specializes in the production of high-performance forged steel balls and is a trusted supplier for global mining operations.

V. Key Considerations for Selecting Mining Grinding Materials

When purchasing grinding materials for your mining operations, several factors should be taken into account to ensure you select the right products for your needs:

Material Compatibility

The type of ore being processed plays a critical role in selecting the right grinding material. Harder ores may require higher toughness and hardness in the grinding balls and mill liners to maintain efficiency and minimize wear.

Wear Resistance

Choose materials with superior wear resistance to prolong the lifespan of your milling equipment and reduce maintenance costs. Forged steel balls tend to have a longer lifespan than cast steel balls, though cast balls are often more cost-effective.

Grinding Efficiency

The shape, size, and surface texture of the grinding balls or mill liners can impact the grinding process. Smooth balls may generate less impact force, while textured balls or liners improve the grinding action, but can increase wear rates.

Cost

Cost is always an important factor. Forged steel balls tend to be more expensive than cast steel balls due to the manufacturing process. However, they may provide better performance and last longer, which can offset the higher initial cost in the long run.

Supplier Reliability

Choose a reliable supplier with a proven track record in the industry. Ensure they provide high-quality products, offer competitive pricing, and have good customer service.

VI. Choose IMEXsourcing as Your Sourcing Partner for steel balls in China

When it comes to procuring high-quality steel balls from China, partnering with an experienced and reliable sourcing agent is paramount. IMEXsourcing stands out as a premier choice, offering a comprehensive suite of services designed to streamline your acquisition process and secure exceptional value. Here are compelling reasons to select IMEXsourcing for your next purchase on steel balls:

Extensive Procurement Expertise

IMEXsourcing boasts a profound and long-standing history in the sourcing industry, enabling us to proficiently locate and secure a wide array of lawn mower types from highly regarded Chinese suppliers. Our deep market knowledge ensures that we connect you with manufacturers known for their reliability and superior products.

Thorough Supplier Verification

Our commitment to quality begins with rigorous due diligence. We conduct comprehensive factory verifications for all potential manufacturers. This meticulous audit confirms their production capabilities, assesses their quality control protocols, and ensures their full compliance with relevant industry standards and legal requirements.

Expert Price Negotiation

Leveraging our veteran status and in-depth understanding of the market dynamics, IMEXsourcing excels in negotiation. This invaluable expertise allows us to secure the most favorable pricing and terms with top-tier manufacturers renowned for their lawn mowers, optimizing your investment.

Stringent Quality Assurance

IMEXsourcing implements a robust quality management framework that spans the entire procurement cycle. This includes careful selection of suppliers, diligent oversight through production inspections, and thorough product testing prior to shipment, guaranteeing the integrity and performance of your equipment.

Optimized Warehouse Management

Our advanced warehouse operations are meticulously designed to facilitate optimal inventory flow and minimize delivery lead times. This efficient system ensures that your equipment consistently arrives promptly from the manufacturer.

Seamless Logistics Handling

We manage the entire logistical chain, from initial transportation and overseas shipping to final delivery directly to your designated location. This end-to-end service guarantees that your lawn mower reach you efficiently and directly from the production facility.

Effortless Customs Processing

Navigating international customs can be complex, but with IMEXsourcing, it's simplified. We take full responsibility for gathering all necessary documentation and ensuring a smooth customs clearance process, alleviating bureaucratic hurdles and streamlining paperwork for our valued partners.

VII. Conclusion

Steel balls are products with notoriously difficult quality control—they may look identical in appearance, but many unethical suppliers often provide qualified samples during the purchasing process, only to substitute them with inferior steel balls in bulk shipments to defraud customers. IMEXsourcing, equipped with extensive experience in steel ball procurement and a reliable legal team, can provide full protection to help you avoid all such risks effectively.