How to Sourcing Soda Ash (Na₂CO₃, Sodium Carbonate) from China

With a chemical formula of Na₂CO₃, commonly known as soda, soda ash, disodium carbonate, or sodium carbonate, it is typically a white powder. It is a strong electrolyte with a density of 2.532 g/cm₃ and a melting point of 851°C. It is freely soluble in water and glycerin, slightly soluble in anhydrous ethanol, and poorly soluble in propanol. It has the general properties of salt and is classified as an inorganic salt. It absorbs moisture and forms lumps in humid air, partially converting to sodium bicarbonate. Sodium carbonate can be produced through the combined alkali process, the ammonia-soda process, and the Leblanc process. It can also be refined from natural alkali. As an important inorganic chemical raw material, it is primarily used in the production of flat glass, glassware, and ceramic glazes. It is also widely used in household cleaning, acid neutralization, and food processing.

This guide provides a comprehensive overview of the Chinese soda ash industry, helping you navigate the market and find the right suppliers. Following the example of a successful sourcing blog, we'll cover everything you need to know about purchasing this essential chemical from China.

I. Introduction to Soda Ash: Types and Applications

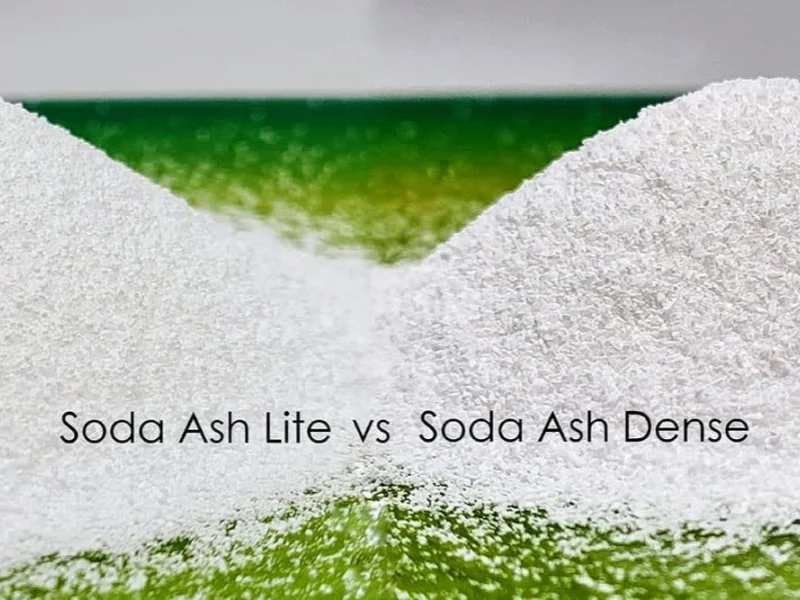

Soda ash, or sodium carbonate (Na₂CO₃), is a fundamental inorganic chemical widely used across various industries. In China, it is primarily categorized into two main types based on density: Light Soda Ash and Dense Soda Ash.

Light Soda Ash: With a bulk density of approximately 500-600 kg/m³, light soda ash is a fine, white powder. It dissolves quickly and is primarily used in light industries. Its major applications include:

Detergents and Soaps: As a builder to improve cleaning efficiency.

Daily-use Glass: In the production of glass bottles, jars, and other household glassware.

Chemicals and Pharmaceuticals: As a raw material for various chemical reactions and medical products.

Inorganic Salts: Manufacturing sodium silicate, sodium metasilicate, and other sodium-based chemicals.

Dense Soda Ash: This type has a higher bulk density, typically ranging from 1000-1200 kg/m³, and appears as larger, granular particles. Its density and particle size make it ideal for high-temperature processes where it won't be easily carried away by heat. Dense soda ash is the preferred choice for:

Float Glass: The largest consumer of soda ash, used in the production of windows, car windshields, and architectural glass.

Photovoltaic Glass: An increasingly important application in the solar energy sector.

Metallurgy: Used as a flux and desulfurizer in steel and antimony refining.

II. Key Advantages of Sourcing Soda Ash from China

China is one of the world's largest producers and exporters of soda ash, offering several advantages for international buyers:

Scale and Capacity: China's soda ash industry boasts massive production capacity, ensuring stable supply and competitive pricing. The sheer volume of production helps buffer against global market volatility.

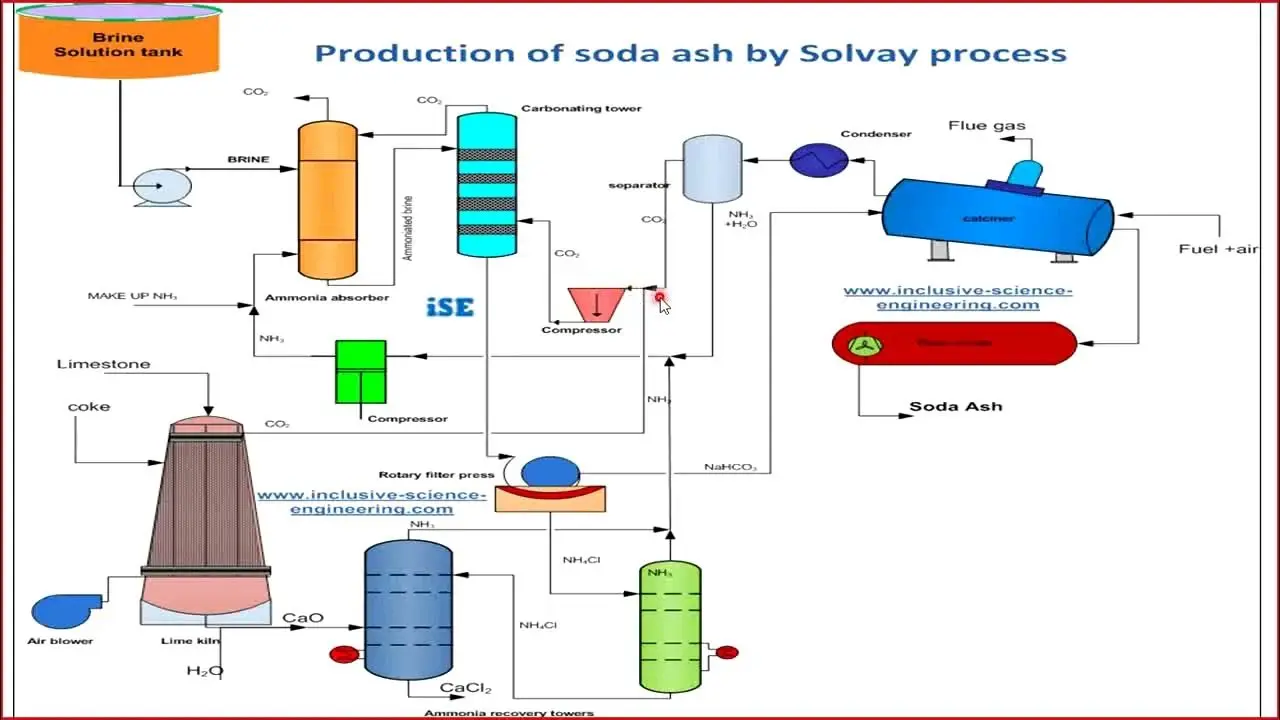

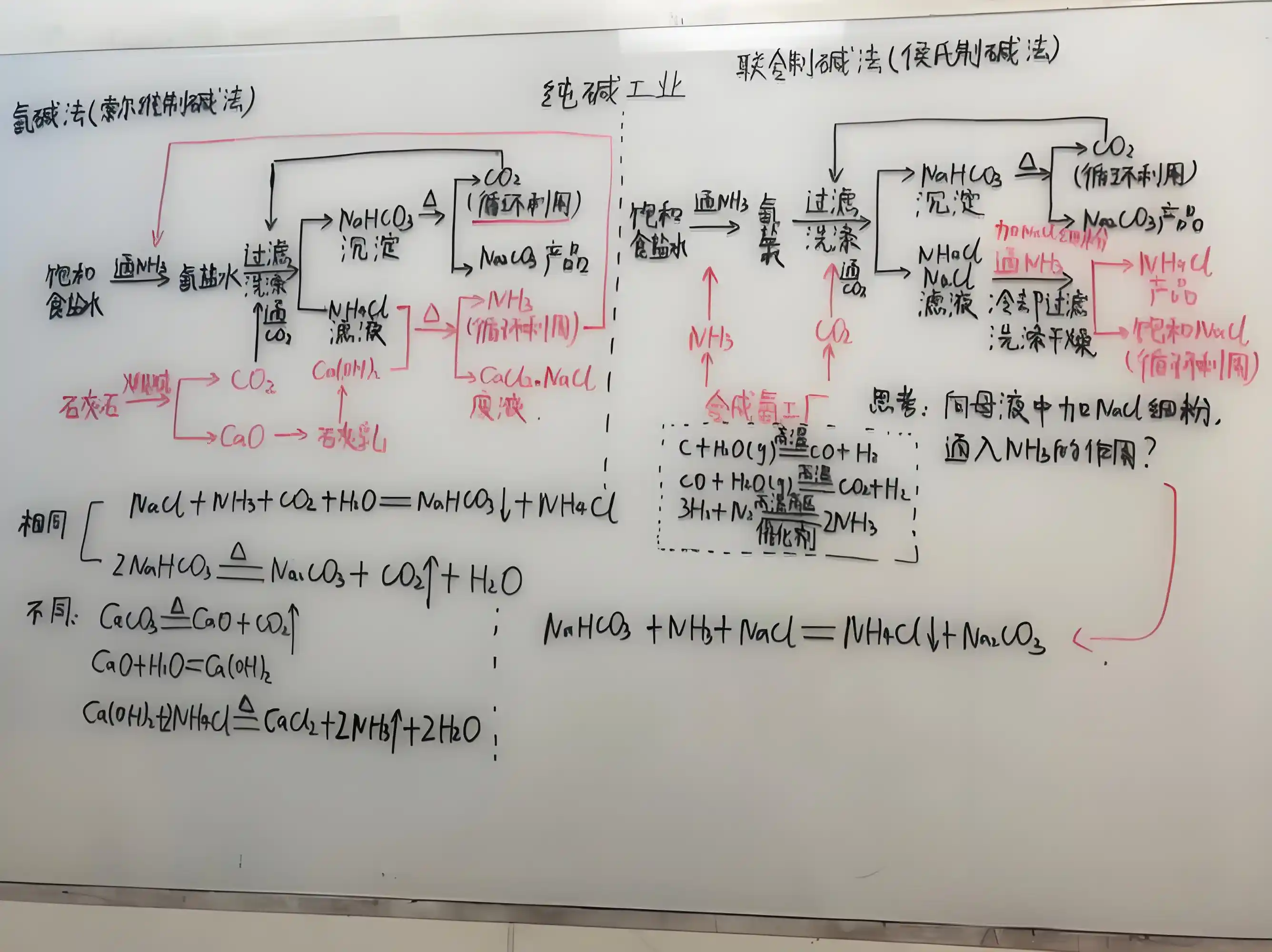

Advanced Production Technology: China employs three main production methods: the Ammonia-Soda Process (氨碱法), the Solvay Process (联碱法), and the Natural Alkali Method (天然碱法). The Natural Alkali Method, in particular, offers significant cost advantages due to its lower energy consumption and reduced environmental impact.

Diverse Product Portfolio: Chinese manufacturers produce both high-quality light and dense soda ash to meet a wide range of industrial requirements, from high-precision glass to basic detergents.

Robust Supply Chain and Logistics: The well-developed logistics infrastructure ensures efficient and reliable delivery, whether by sea or land. Many large manufacturers are located near major ports, simplifying the export process.

III. Main Specifications and Technical Parameters

When procuring soda ash, it is crucial to understand the key technical specifications. These parameters ensure the product meets your exact requirements.

Chemical Purity: The most important parameter is the concentration of Na₂CO₃, which typically should be over 99.2% for industrial grade.

Bulk Density: This is the primary difference between light and dense soda ash.

Light Soda Ash: 500-600 kg/m³

Dense Soda Ash: 1000-1200 kg/m³

Particle Size: Particle size distribution is critical, especially for dense soda ash used in glass manufacturing, as it affects the mixing process and prevents airborne loss.

Impurities: The levels of impurities like chlorides, sulfates, and iron content must be within acceptable limits for specific applications.

Moisture Content: Low moisture content is essential to prevent caking during storage and transport.

IV. Industry Clusters and Major Production Hubs

China's soda ash manufacturing is geographically concentrated in several key regions. These clusters have developed robust supply chains, advanced infrastructure, and skilled labor.

Shandong Province: A long-standing hub for chemical production, Shandong is home to some of the largest soda ash manufacturers. Companies in cities like Weifang and Qingdao are known for both their scale and established market presence.

Hebei Province: With a strategic location near Beijing and Tianjin, Hebei's chemical industry is well-developed, with several significant players contributing to the national output.

Jiangsu Province: Known for its thriving chemical and pharmaceutical sectors, Jiangsu also has a strong presence in the soda ash industry, particularly for light soda ash production.

Central China (Henan, Hubei): These provinces have growing chemical industries and benefit from their central location, which facilitates distribution to both northern and southern markets.

Qinghai Province: A key region for the Natural Alkali Method, Qinghai's producers leverage vast natural resources to offer cost-competitive products. This region is becoming increasingly important for high-volume production.

V. Leading Manufacturers in China

Here are some of the most prominent soda ash manufacturers in China, categorized by their production method. These companies are industry leaders with a strong reputation for quality and reliability.

Natural Alkali Method:

Berun Chemical (博源化工) (Former Name: Yuanxing Energy /远兴能源): http://www.yuanxing.com A leader in the natural alkali method, known for its cost-effective and large-scale production.

Solvay Process (联合制碱法): This method produces both soda ash and ammonium chloride, a valuable byproduct.

Hebang Biotech (和邦生物): https://hebang.cn A significant player in Sichuan Province in the southernwest China with a focus on both soda ash and other chemical products.

Shuanghuan Technology (双环科技): https://www.hbshkj.cn A well-established company in Middle China's Hubei Province with a strong market presence.

Huachang Chemical (华昌化工): https://www.huachangchem.cn Known for its diversified chemical product portfolio, including soda ash.

Yuntu Holdings (云图控股), also known as Wintrue: https://www.wintrueholding.com A major producer with a focus on comprehensive chemical solutions.

Ammonia-Soda Process (氨碱法):

Zhongyan Chemical (中盐化工), also known as China Salt Chemical: https://www.chinasaltchemical.com One of the largest state-owned chemical companies, a major producer of soda ash.

Sanyou Chemical (三友化工): http://www.sanyou-chem.com.cn A diversified company with significant production capacity in soda ash and other chemicals.

Shandong Haihua (山东海化): https://www.haihua.com.cn A key player in Shandong Province, known for its large-scale operations, listed in the year 1998.

Shandong G-Crystal (山东金晶): https://www.jinjing-glass.com The second key player in Shandong Province, famous for its high end glasses. The soda ash factory is run itself for glass produciton as well as exporting.

Lianyungang Soda Ash (连云港碱业): http://www.lygsoda.com/ Located in a coastal city for export, offers both light, dense, sodium bicarbonate etc.

VI. Relevant Certifications and Quality Standards

Ensuring product quality and environmental compliance is paramount. When selecting a Chinese supplier, look for the following certifications and standards:

ISO 9001: Demonstrates a company's commitment to quality management systems. This is a fundamental certification for any reputable manufacturer.

Clean Production Standards (清洁生产标准纯碱行业): Issued by the Chinese government, this standard outlines strict requirements for equipment, resource utilization, energy consumption, and pollutant discharge. Suppliers who meet these standards are recognized for their environmental responsibility.

Energy Management System Certification: This shows that a company has a systematic approach to improving energy performance, including efficiency, use, and consumption.

REACH and other international chemical regulations: Reputable suppliers should be able to provide documentation proving their products comply with the chemical regulations of your target market, such as Europe's REACH.

VII. Essential Tips for a Successful Procurement

To ensure a smooth and successful procurement process, keep the following points in mind:

Specify Your Requirements Clearly: Be very specific about whether you need light or dense soda ash and provide a detailed list of required specifications. Small differences in purity or particle size can significantly affect the product's performance in your application.

Check Production Methods: The production method can influence cost and quality. Natural alkali-based products often have a cost advantage.

Verify Certifications: Always request and verify up-to-date certification documents. This is your primary way to ensure product quality and ethical manufacturing practices.

Leverage Industry Reputation: Partner with well-known manufacturers and "brand-free inspection system" (免检品牌制度) approved suppliers, as they often offer greater stability and reliability.

Conduct Quality Inspections: For large-volume orders, consider third-party quality inspections before shipment. This can include checking for caking, moisture content, and chemical composition.

Understand Logistics and Delivery: Clarify the delivery terms, including packaging, shipping method (typically by sea in 25kg or 50kg bags), and any specific handling requirements.

VIII. Choose IMEXsourcing as Your Sourcing Partner for Soda Ash in China

When it comes to sourcing high-quality Soda Ash from China, partnering with a trusted and experienced sourcing agent is essential. IMEXsourcing is a leading choice, offering end-to-end procurement services that simplify the process and maximize your return on investment. Here are the key reasons to choose IMEXsourcing for your next Soda Ash procurement project:

Extensive Sourcing Expertise

With years of experience in the global sourcing industry, IMEXsourcing possesses in-depth knowledge of China’s chemical supply chain. We have built strong connections with reputable Soda Ash manufacturers, enabling us to efficiently identify and source a wide range of products that meet international quality standards.

Customized Procurement Solutions

We understand that different industries and applications require specific formulations and specifications. IMEXsourcing offers fully customized sourcing solutions, allowing you to procure Soda Ash that is precisely tailored to your technical and operational needs, whether light or dense grade, packaged in bulk or bags.

Comprehensive Supplier Verification

Quality begins with selecting the right partner. IMEXsourcing conducts thorough audits and factory verifications to assess production capacity, quality control systems, compliance with regulatory standards, and overall reliability. This ensures that you only work with qualified and certified Soda Ash producers.

Strategic Price Negotiation

Thanks to our strong supplier relationships and deep market insight, we excel at negotiating competitive pricing and favorable terms. IMEXsourcing ensures that you receive not only high-quality Soda Ash, but also cost-effective solutions that optimize your purchasing budget and enhance profitability.

Reliable and Continuous Supply Chain Support

As a fundamental industrial chemical, Soda Ash is in high demand across a wide range of sectors including glass manufacturing, detergents, chemicals, and metallurgy. IMEXsourcing has the resources, networks, and proven strategies to secure first-hand supply channels directly from leading manufacturers. We ensure a stable, long-term supply that supports uninterrupted production for our clients—helping you avoid costly delays and maintain operational continuity.

End-to-End Quality Assurance

From supplier selection to final shipment, IMEXsourcing enforces strict quality control at every stage of the procurement cycle. We monitor production, conduct in-process and pre-shipment inspections, and oversee independent product testing when necessary—ensuring that your Soda Ash meets all performance and safety requirements.