When making a key business purchase—like vibrating screen mesh (vital for mining, food processing, or waste sorting)—navigating the global market can be tricky. As a top manufacturing hub, China offers a wide range of these specialized meshes, from heavy-duty abrasion-resistant types to precision-grade options. This guide breaks down keyurcing steps: defining mesh specs, vetting suppliers, and ensuring compliance.

This procurement guide covers all you need for informed decisions when importing vibrating screen mesh from China—including product types, key advantages, technical specs, major manufacturing hubs, top firms, certification needs, and critical purchasing considerations.

Table of Contents

I. Product Type Introduction

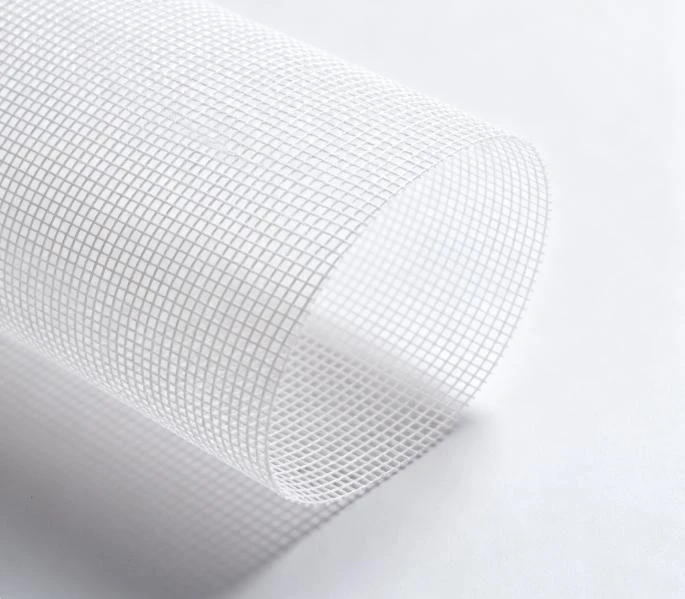

China’s wire mesh market is highly diverse, meeting nearly all application needs. Understanding different wire mesh types is the first step to finding the right product.

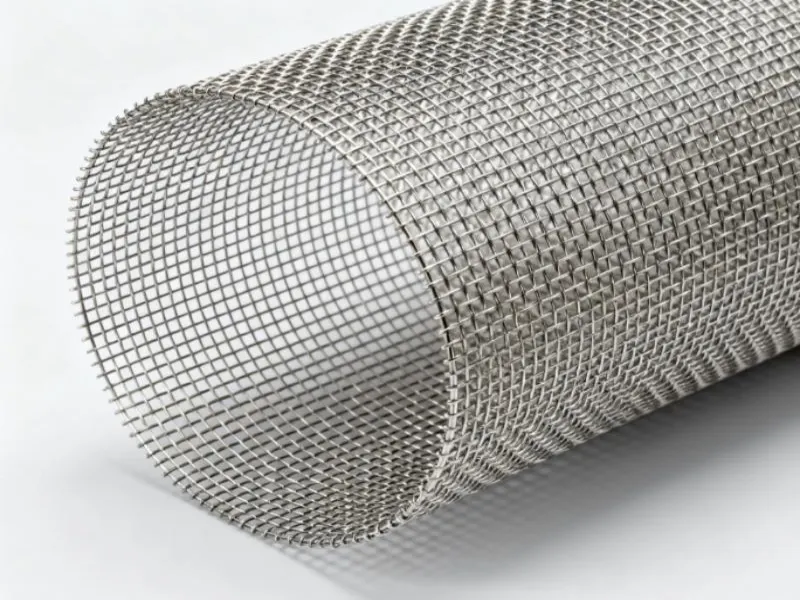

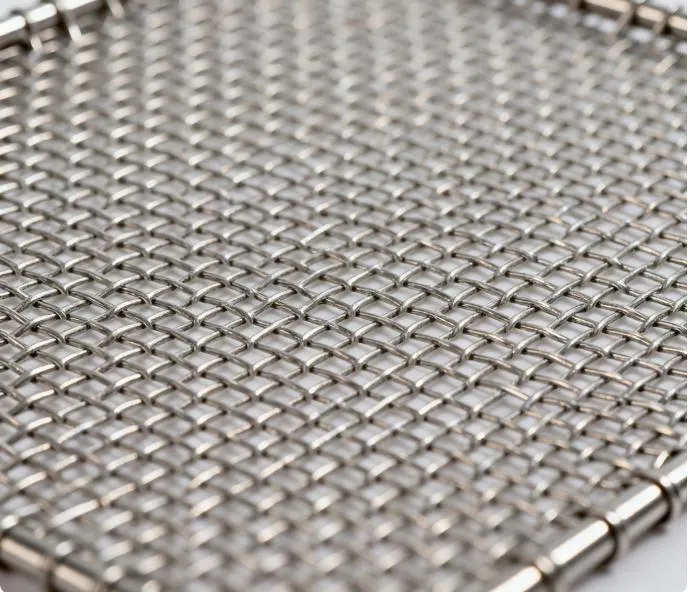

- Stainless Steel Mesh: Corrosion-resistant, high-strength; used in food processing, chemical filtration

- Galvanized Mesh: Zinc-coated for rust prevention; used in agricultural fencing, construction protection

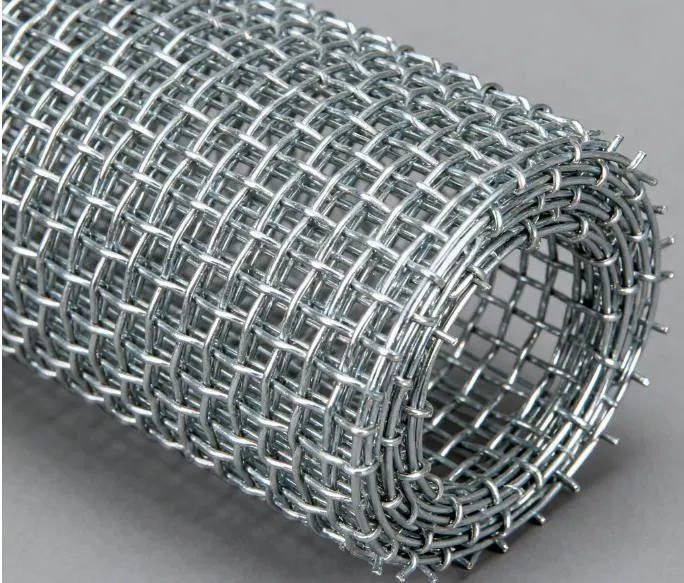

- Woven Wire Mesh: Warp-weft interwoven, uniform aperture; suitable for particle screening

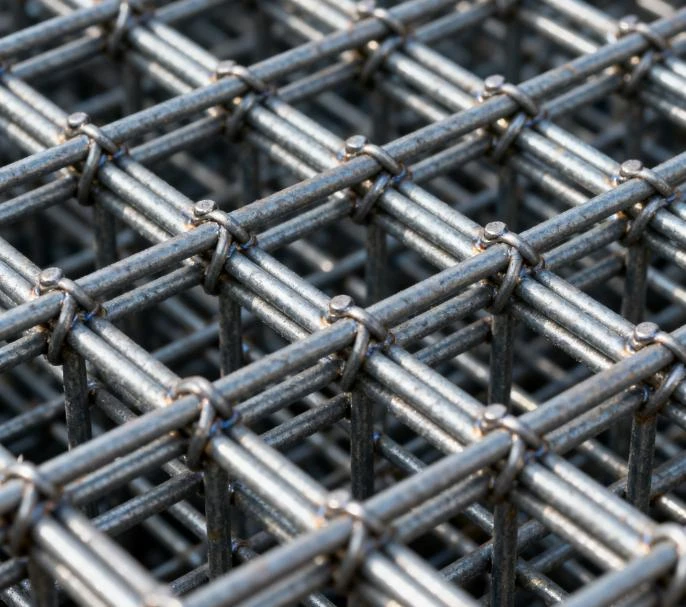

- Welded Wire Mesh: Strong welds, stable structure; used as protective nets, concrete reinforcement

- Nylon Mesh: Lightweight, acid-alkali resistant; used in fine filtration。

II. Multifunctional Advantages: Why Chinese Wire Mesh Stands Out

Chinese manufacturers have refined the production of wire mesh—their products are not only cost-effective but also highly functional, catering to a wide range of application needs.

- 1. Outstanding cost-effectiveness: Low purchase cost, high durability, and controllable long-term usage costs.

- 2. Extensive product range: Covers various materials like stainless steel and nylon, adapting to different scenario needs.

- 3. Wide adaptability: Customizable specifications to meet demands in industries, agriculture, food processing, etc.

III. Main Specifications and Parameters

When placing an order for wire mesh, it’s crucial to clarify the key technical specifications that define the mesh’s performance and suitability.

1. Material (e.g., stainless steel, galvanized steel, nylon): Determines core performance like corrosion resistance and strength of the wire mesh;

2. Mesh specification (aperture size/mesh count): Affects screening precision, suitable for filtering different particles or impurities;

3. Wire diameter: Related to the load-bearing capacity and service life—thicker wires are more durable, while thinner ones fit fine screening;

4. Dimension (roll/sheet specification): E.g., 1m×2m sheets, 50m×1.2m rolls, matching different application scenarios;

5. Weaving/welding process: Woven mesh has uniform apertures, and welded mesh has a stable structure, adapting to different strength requirements.

IV. Industrial Clusters: Where to Find Wire Mesh Manufacturers in China

The wire mesh manufacturing industry in China is highly concentrated in specific regions, with each cluster boasting its own unique strengths.

- Laiwu & Zibo, Shandong Industrial Cluster: An important base for China’s wire mesh industry; its total production capacity together with the Xinxiang, Henan industrial base accounts for 62% of the national total. Relying on the advantages of the Yangtze River Delta’s metal wire industrial chain, it has outstanding performance in wire mesh production capacity.

- Anping, Hebei Industrial Cluster: Known as the “Capital of China’s Wire Mesh”, it is the world’s largest wire mesh industrial base. In 2024, the output value of the wire mesh industry reached 106.7 billion yuan, with the production and sales volume of woven wire mesh accounting for over 80% of the national total.

- Taizhou, Jiangsu Industrial Cluster: An important base for China’s wire mesh industry; its total production capacity together with the Xinxiang, Henan industrial base accounts for 62% of the national total. Relying on the advantages of the Yangtze River Delta’s metal wire industrial chain, it has outstanding performance in wire mesh production capacity.

- Taihe, Anhui Industrial Cluster: It mainly produces polyester mesh and metal mesh, and leads the nation in segmented fields such as papermaking mesh, printing mesh, and coal washing mesh. The industrial output value reached 3.75 billion yuan in 2019.

V. Domestic Major Manufacturers (Leading Enterprises)

The Chinese wire mesh market is dominated by several key players, which stand out for their product quality, technological innovation, and production scale.

- Anping Guangming Wire Mesh Factory: The factory has strong technical strength, advanced loom equipment, and a complete quality inspection system. It uses high-quality raw materials, and its products are complete in specifications and excellent in quality. The main products include mud vibrating screen mesh, oil sand control pipe, stainless steel mesh, wound wire screen pipe, etc., which are widely used in many industries such as petroleum, chemical, construction, and medicine. Its “Hengying” brand wire mesh products are not only sold well across the country but also exported to countries such as the United States, Canada, and the United Kingdom

- Binzhou Wosen Wire Mesh Co., Ltd.: The factory has focused on the wire mesh field for over 20 years, boasting notable achievements in custom non-standard slotted wire mesh. Its independently developed polyurethane composite technology boosts the mesh’s wear resistance by 70% and achieves industry-leading tensile strength; its custom slotted wire mesh, with a slot precision of ±0.02mm, holds an 18% market share in stone and coal screening.

- Xinxiang Xinhang Wire Mesh Filter Co., Ltd.,: located in Xinxiang, Henan Province, is a key enterprise in China’s high-end wire mesh weaving field. It mainly produces standard classification screens, test sieves, electroformed sieves, etc. Its newly developed dense mesh holds over 80% market share, while its test sieves take over 50% of the high-end market; it also participates in formulating international standards for test sieves and wire meshes.

VI. Relevant Certification Requirements

Exporting wire mesh from China requires compliance with a complex set of international certifications and standards; ensuring suppliers meet these regulations is crucial to avoid customs issues.

Exporting wire mesh to different markets requires corresponding certifications:

- For the EU, CE certification (proving compliance with safety, health and other directives) is needed;

- For the US, FDA certification (for food-contact wire mesh) or ASTM standards (for general industrial wire mesh) are required;

- For some countries in the Middle East and Southeast Asia, certifications like SASO (Saudi Arabia) and SIRIM (Malaysia) are necessary to meet local quality regulations.

VII. Precautions for Purchasing: Making an Informed Decision

Once you have identified potential suppliers and their products, follow these steps to secure a successful purchase.

- Start with Samples: Before placing a large order, it’s highly recommended to order samples. This allows you to visually assess the wire mesh’s craftsmanship, material and performance, and test its aperture precision, wear resistance and load-bearing capacity.

- Assess Supplier Production Capacity: A supplier’s production capacity is key to meeting your needs, especially for large orders. Inquire about their production metrics and delivery timelines—well-established, high-output manufacturers handle bulk orders more efficiently.

- Define Intended Use Clearly: Specify your target market and the wire mesh’s purpose—for food filtration or ore screening? Different needs will determine the required aperture specification, material and temperature resistance.

- Consider After-Sales Support: A reliable supplier should offer after-sales support, including spare parts supply and technical assistance. Inquire about their warranty policy and how they handle repairs or part replacements.

- Calculate Total Cost: Beyond the unit price, include shipping fees, import duties, customs clearance costs, local taxes, and potential costs for modifications or a separate warranty program.

- Perform Due Diligence: Use online tools like Alibaba’s “Audited Supplier” badge or third-party inspection services to verify a supplier’s qualification and factory conditions, and ask for references from other international buyers.

VIII. Choose IMEXsourcing as Your Sourcing Partner for Tricycles in China

When procuring high-quality wire mesh from China, partnering with an experienced and reliable sourcing agent is paramount. IMEXsourcing stands out as a premier choice, offering comprehensive services to streamline your procurement process and secure exceptional value. Here are compelling reasons to select IMEXsourcing for your next wire mesh purchase:

- Extensive Procurement Expertise

IMEXsourcing has a long-standing, profound history in the sourcing industry, enabling it to proficiently locate and secure a wide range of wire mesh from reputable Chinese suppliers. Its deep market knowledge ensures connection with manufacturers known for reliability and superior products.

- Bespoke Design Solutions

At IMEXsourcing, we understand unique needs often require tailored solutions. We help you commission well-designed custom wire mesh or source standard wire mesh, ensuring the final product perfectly meets your operational requirements.

- Thorough Supplier Verification

Our commitment to quality begins with rigorous due diligence. We conduct comprehensive factory verifications for all potential manufacturers. This meticulous audit confirms their production capabilities, assesses their quality control protocols, and ensures their full compliance with relevant industry standards and legal requirements.

- Expert Price Negotiation

With its veteran industry experience and in-depth understanding of market dynamics, IMEXsourcing excels in negotiations. This expertise enables it to secure the most favorable pricing and terms with top-tier wire mesh manufacturers—renowned for quality, functionality, after-sales service and cost-efficiency—optimizing your investment.

- Stringent Quality Assurance

IMEXsourcing implements a strict quality management framework across the entire procurement cycle, covering careful supplier selection, diligent production inspection oversight, and thorough pre-shipment product testing—guaranteeing the reliability and performance of your wire mesh.

IX. Conclusion

In conclusion, the Chinese wire mesh market offers abundant opportunities for global buyers. By carefully researching product types, clarifying technical specifications, and following a structured procurement process, importers can source high-quality, cost-effective wire mesh to meet various commercial and industrial needs.

Moreover, engaging with reputable suppliers and conducting thorough due diligence ensures that the procurement process is not only efficient but also minimizes risks associated with international trade. This strategic approach not only enhances the value proposition but also fosters long-term business relationships, ultimately contributing to sustained profitability and market competitiveness.