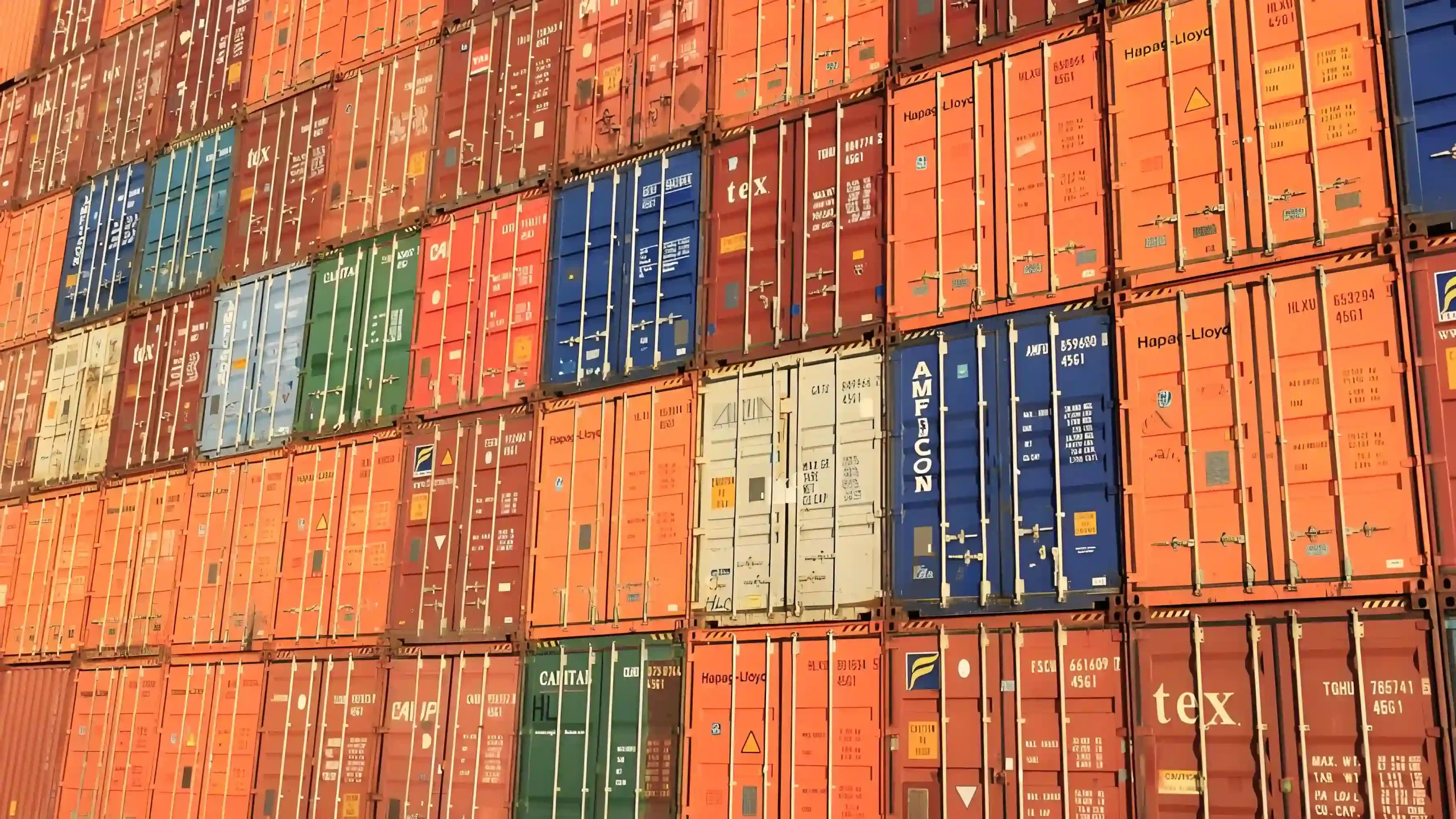

China stands as the undisputed global leader in shipping container manufacturing, producing an overwhelming majority of the world’s containers. For businesses worldwide, sourcing containers directly from China offers significant advantages, including competitive pricing, vast production capacity, and a wide array of specialized options. This guide delves into the intricacies of procuring shipping containers from China, covering everything from product types and specifications to key manufacturers, essential certifications, purchasing considerations, and the strategic advantages of using Shipper-Owned Containers (SOCs).

Table of Contents

I. Introduction to Chinese Container Manufacturing

The Chinese container industry has witnessed exponential growth since its inception in the late 1970s and early 1980s. What began with modest production has transformed into a colossal industry, with China accounting for over 96% of the world’s container manufacturing capacity. This dominance is not just in volume but also in diversity, with over 900 types of containers now produced to meet varied global demands. The continuous surge in production, even surpassing previous records, underscores China’s pivotal role in supporting global trade and logistics. This robust manufacturing ecosystem ensures that despite global trade fluctuations, the supply of new containers remains abundant, mitigating equipment shortages.

II. Product Type Overview: From General Purpose to Specialized Solutions

China’s container manufacturers offer an extensive range of container types, each designed for specific cargo requirements. Understanding these types is crucial for making informed purchasing decisions:

-

General Purpose Dry Containers (普柜 – Standard Containers): These are the most common type, used for transporting various dry goods. They are fully enclosed, wind and watertight, and come in standard lengths like 20ft and 40ft.

-

Refrigerated Containers (冻柜 – Reefer Containers): Also known as “reefers,” these are equipped with a refrigeration unit to maintain a constant temperature, essential for transporting perishable goods such as food, pharmaceuticals, and chemicals.

-

High Cube Containers: Similar to general-purpose containers but with an additional foot in height (typically 9.5 feet tall), providing extra cubic capacity for light, voluminous cargo.

-

Open Top Containers: These containers have a removable tarpaulin roof instead of a solid one, allowing for easy loading of oversized cargo (e.g., machinery, tall equipment) from the top.

-

Flat Rack Containers: These feature collapsible sides or no sides at all, designed for oversized or oddly shaped cargo that cannot fit into standard containers. They are ideal for heavy machinery, vehicles, or timber.

-

Tank Containers (ISO Tank Containers): Constructed from robust steel or anti-corrosive materials, these are specifically designed for the safe transportation of liquids, gases, and powders.

-

Open Side Containers: Also known as “side door containers,” these have doors that open along the entire long side, facilitating easy loading and unloading of cargo that requires wider access.

-

Insulated Containers: These are built like a “thermos” bottle, maintaining a stable internal temperature without active cooling, suitable for goods that need protection from extreme temperature fluctuations.

-

Specialized Containers (各种特种集装箱 – Various Special Containers): This category encompasses a wide array of customized containers, including:

-

Bulk Containers: For granular or powdered materials.

-

Ventilated Containers: For goods requiring air circulation.

-

Car Carriers: Designed to transport vehicles.

-

Workshop/Accommodation Containers: Modified for specific on-site uses.

-

Offshore Containers: Built to withstand the harsh conditions of offshore environments, meeting stringent DNV standards.

-

Beyond new containers, the market also offers used containers (二手集装箱) and one-trip containers (新集装箱). One-trip containers are essentially new containers that have made a single journey with cargo from their manufacturing origin (often China) and are then sold. They offer a cost-effective alternative to brand-new containers while still being in excellent condition. Used containers, categorized as “cargo-worthy” (seaworthy) or “wind and watertight” (suitable for storage), provide even more economical options.

III. Key Specifications and Parameters

Standardization is paramount in the global shipping industry, largely governed by ISO (International Organization for Standardization) standards. The most common container sizes and their typical specifications are:

Materials: Modern shipping containers are primarily constructed from Corten steel (also known as “weathering steel”), which is highly resistant to corrosion. Key components include:

-

Body: 16-gauge vertically corrugated Corten steel.

-

Doors: Double, asymmetrical steel doors with ground-level entry and robust locking bars.

-

Flooring: Heavy-duty, marine-grade wood (typically plywood or bamboo).

-

Roofing: Die-stamped steel.

-

Corner Fittings: Casted weldable steel, crucial for stacking and lifting.

Containers are designed to withstand extreme temperatures ranging from -40°C (-40°F) to +70°C (+158°F) without compromising their structural integrity or watertightness.

IV. Industry Clusters and Key Manufacturing Hubs

While container manufacturing plants are spread across China, the industry naturally clusters around major port cities, which serve as crucial logistics and export hubs. These areas provide easy access to raw materials, skilled labor, and most importantly, efficient shipping routes for container distribution.

Key regions and cities that are significant in China’s container industry include:

-

Shenzhen/Guangdong Province: As a major export-oriented economy in South China, Guangdong Province, particularly Shenzhen, is a prime location for container manufacturing due to its proximity to one of the world’s busiest ports (Port of Shenzhen) and established industrial infrastructure.

-

Shanghai/Yangtze River Delta: Shanghai, with its massive Yangshan Deep-Water Port and Waigaoqiao Port Area, is a critical hub. The surrounding Yangtze River Delta region is a manufacturing powerhouse, supporting container production and related industries.

-

Qingdao/Shandong Province: Qingdao is another significant port city with established container manufacturing facilities, benefiting from its strategic location for Northern China’s trade.

-

Tianjin: Close to Beijing, Tianjin also hosts major container production facilities, serving as a key gateway for northern China.

-

Ningbo-Zhoushan: This port, one of the world’s largest by tonnage and container capacity, also facilitates the container industry in its vicinity.

These areas provide the necessary ecosystem, including steel suppliers, labor, and efficient logistics, to support the high-volume production of shipping containers.

V. Leading Chinese Manufacturers of Shipping Containers

China is home to the world’s largest and most reputable container manufacturers. These companies dominate the global market with their immense production capacities and diversified product portfolios.

-

CIMC (China International Marine Containers Group Co., Ltd.): https://www.cimc.com CIMC is by far the largest container manufacturer globally, headquartered in Shenzhen. They produce a comprehensive range of transportation equipment, including dry freight containers, reefer containers, special containers, modular buildings, and road transport vehicles. Their innovation and scale make them a preferred choice for many global buyers.

-

COSCO Shipping Development Co., Ltd.: http://en.development.coscoshipping.com As a subsidiary of China COSCO Shipping Corporation Limited, one of the world’s largest shipping conglomerates, COSCO Shipping Development is a major player in container manufacturing. They produce dry, reefer, and special containers, with a significant emphasis on research and development.

-

Singamas Container Holdings Limited: https://www.singamas.com Headquartered in Shanghai, Singamas is another leading manufacturer with multiple production factories across China. They specialize in dry freight containers, collapsible flat-rack containers, tank containers, offshore containers, and other specialized units.

-

CXIC Group Containers Company Limited: http://en.cxic.com Based in Changzhou, CXIC has been a key manufacturer of dry cargo, special, and tank containers since 1996. They boast a substantial annual manufacturing capacity and export a large percentage of their products globally.

-

Dong Fang International Container (Hong Kong) Ltd.: https://www.oocl.com While listed as Hong Kong-based, Dong Fang operates significant manufacturing facilities in mainland China and is considered one of the largest container manufacturing groups.

These companies are renowned for their quality, adherence to international standards, and capacity to handle large-scale orders.

VI. Relevant Certification Requirements

Ensuring the quality, safety, and international compatibility of shipping containers is paramount. Chinese manufacturers adhere to a stringent set of international standards and certifications:

-

ISO (International Organization for Standardization): All standard shipping containers must comply with ISO standards, particularly ISO 6346, which defines container coding, identification, and marking, and ISO 1496, which specifies container dimensions and structural requirements.

-

CSC (International Convention for Safe Containers): This convention, ratified by the IMO (International Maritime Organization), ensures that containers used in international transport are safe. All new containers must have a valid CSC plate, indicating they have passed structural tests and are approved for international shipping. This certification is crucial for safety and intermodal transport.

-

Classification Societies (e.g., DNV, RINA, Lloyd’s Register, Bureau Veritas): For specialized containers, particularly offshore containers, certifications from reputable classification societies are often required. DNV (Det Norske Veritas) is particularly prominent for its DNV 2.7-1 standard for offshore containers, ensuring they can withstand harsh marine environments and are safe for lifting and transport on offshore installations.

-

ADR (European Agreement Concerning the International Carriage of Dangerous Goods by Road): For tank containers carrying dangerous goods, compliance with ADR regulations is essential for road transport within Europe.

-

IMDG (International Maritime Dangerous Goods Code): This code, also from the IMO, sets out regulations for the safe transport of dangerous goods by sea. Tank containers and certain specialized containers must comply.

-

RID (International Regulations Concerning the Carriage of Dangerous Goods by Rail): Similar to ADR, RID applies to the rail transport of dangerous goods.

-

UIC (International Union of Railways): Relevant for containers designed for intermodal rail transport, ensuring compatibility with railway systems.

When purchasing containers, especially new ones, buyers must verify that all necessary certifications are in place, confirming the container’s structural integrity, safety, and compliance with international shipping regulations.

VII. Purchasing Considerations: A Buyer’s Guide

Sourcing shipping containers from China requires careful planning to ensure a smooth and successful transaction.

-

Define Your Needs Clearly: Before anything else, precisely determine the type, size, and quantity of containers you need. Consider the cargo type, transport mode, and any specific environmental conditions. Do you need a new (one-trip) container for pristine condition or a used “cargo-worthy” or “wind and watertight” unit for more budget-friendly storage?

-

Identify Reputable Suppliers/Manufacturers: Focus on established manufacturers with a proven track record. Leverage online marketplaces with vetted suppliers or work with experienced sourcing agents. Verify their production capacity, quality control processes, and export experience. Websites often feature client testimonials and case studies.

-

Request Detailed Quotations: Obtain comprehensive quotes that include:

-

Container unit price.

-

FOB (Free On Board) or EXW (Ex Works) pricing.

-

Any customization costs.

-

Packaging costs (if applicable).

-

Lead time for production and delivery.

-

Payment terms and methods.

-

-

Quality Inspection: For large orders, consider arranging a third-party inspection (e.g., SGS, Bureau Veritas) at the factory before shipment. This ensures that the containers meet agreed-upon specifications and quality standards. For used containers, detailed photo/video inspection or a physical survey is crucial.

-

Payment Terms: Be cautious with upfront payments. Reputable suppliers typically require a deposit (e.g., 30%) with the balance due upon completion or before shipment. Consider using secure payment methods like Letters of Credit (LC) for larger transactions.

-

Logistics and Freight Forwarding:

-

Work with an Experienced Freight Forwarder: This is crucial. A good freight forwarder will manage the entire shipping process from China to your destination, including booking cargo space, handling customs clearance, and arranging inland transport. They can advise on the best shipping routes and consolidate shipments if needed.

-

-

Understand Incoterms: Familiarize yourself with Incoterms (e.g., FOB, CIF, EXW) to clarify responsibilities and costs between you and the supplier at different stages of the shipping process.

-

Customs Clearance and Documentation: Ensure all necessary documentation is accurate and complete, including the commercial invoice, packing list, bill of lading, and any required import licenses or certificates. Inaccurate documentation can lead to delays and penalties.

-

-

After-Sales Service: Inquire about the manufacturer’s warranty and after-sales support for any potential issues or defects.

VIII. The Strategic Advantage of Shipper-Owned Containers (SOCs)

In international logistics, shippers primarily use two types of containers: Carrier-Owned Containers (COCs) and Shipper-Owned Containers (SOCs). While COCs are provided by the shipping line and are common, SOCs offer distinct advantages, particularly for specific shipping needs.

What are SOCs?

SOCs are containers that are owned or leased by the shipper (the cargo owner) rather than the shipping line. The shipper is responsible for the container’s maintenance, repositioning, and return.

Advantages of Using SOCs:

-

Cost Savings (Avoiding Demurrage & Detention): This is arguably the biggest benefit. Demurrage charges are fees incurred when a container stays too long at the port or terminal beyond the agreed-upon free days, while detention charges apply when a container is held by the consignee beyond the free time outside the port. With SOCs, you are not subject to these carrier-imposed fees, offering significant savings, especially during port congestion, unforeseen delays, or when shipping to remote locations with limited infrastructure.

-

Greater Flexibility in Routes and Schedules: COCs are often restricted to a carrier’s specific routes and schedules. SOCs provide shippers with the freedom to choose any carrier, route, or delivery schedule that best suits their needs. This flexibility is invaluable for shipping to distant or less popular destinations where COC availability might be limited.

-

Control over Container Quality: When purchasing or long-term leasing an SOC, you have direct control over the container’s condition and quality. This is particularly important for sensitive cargo that requires specific container standards (e.g., for food-grade cargo or high-value goods).

-

Reduced Dependency on Carrier Equipment: In times of container shortages or high demand, relying solely on COCs can lead to delays and increased costs. Owning or leasing SOCs reduces this dependency, providing a more resilient supply chain.

-

Easier Empty Container Repositioning: For long-term or frequent shippers, especially those with imbalanced trade lanes, managing empty container repositioning can be a significant challenge with COCs. With SOCs, you have more control over where the empty container goes next, potentially using it for a new shipment or selling it at the destination, thereby avoiding costly empty repositioning fees charged by carriers.

-

Suitable for Specialized Shipments: For unique or oversized cargo requiring custom container modifications, SOCs are often the only viable option as carriers typically do not provide highly specialized units.

-

Better Budgeting and Predictability: By owning or long-term leasing containers, businesses can better predict and control their shipping costs, as they are not subject to fluctuating spot rates for COC usage or unexpected demurrage/detention charges.

While SOCs offer numerous advantages, they also entail the responsibility for maintenance, repair, and potential repositioning costs if not planned strategically. However, for businesses with substantial and consistent shipping volumes, or those frequently dealing with remote destinations and potential delays, the strategic advantages of SOCs often outweigh the challenges.

IX. Conclusion

China’s dominance in shipping container manufacturing presents an unparalleled opportunity for global buyers. By understanding the diverse product offerings, key specifications, leading manufacturers, and critical certification requirements, businesses can confidently navigate the procurement process. Furthermore, leveraging the strategic advantages of Shipper-Owned Containers can lead to significant cost savings and enhanced logistical flexibility. As global trade continues to evolve, sourcing containers from China remains a cornerstone for efficient and cost-effective international supply chains.