Table of Contents

I. Introduction: The Core Engine of Global Oil Production

The Oil Press Machine is the central equipment in global edible and industrial oil production lines, covering specialized machinery for processing diverse oilseeds, from peanuts and soybeans to sesame and crucially, palm oil. Through precise pressing techniques, these machines ensure highly efficient oil separation and maintain the quality of the final product.

China dominates the global manufacturing and export of oil press equipment. Benefiting from a complete industrial chain, significant scale advantages, and continuous technical upgrades—including high-yield cold-pressing technology and compliance with international food safety standards—Chinese-made machinery is the preferred choice for global buyers. This guide aims to equip international buyers with essential knowledge to efficiently connect with top-tier Chinese manufacturers and source customized, high-performance oil pressing solutions tailored to various oil processing requirements.

II. Oil Press Machines: Key Equipment for Efficient Extraction and Main Classifications

The Oil Press Machine (also known as an Oil Expeller) is central to the oil processing industry, functioning to separate oil from oil-bearing crops through physical mechanical methods. It is widely used for processing raw materials like rapeseed, peanuts, soybeans, sesame, sunflower seeds, and importantly, palm fruit. The design and operational mechanism of the oil press directly impact both the final oil yield and quality. Based on their working principle and scale of application, modern oil press machines are primarily categorized into three main types:

- Screw Press Machine: The most common type. It generates immense thrust and friction inside a press cage using a rotating screw to continuously squeeze the raw material. Screw presses are simple in structure and suitable for various oilseeds and production scales, from small farms to large factories.

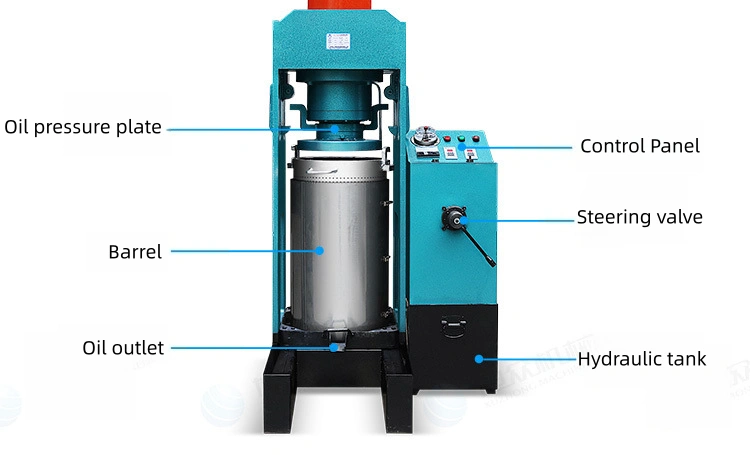

- Hydraulic Press Machine: This type relies on a hydraulic system to generate tremendous static pressure to expel oil. Since the pressing process involves no heating, it is ideal for cold pressing, preserving the maximum nutritional value and flavor of specialty oils (like sesame oil or olive oil).

- Pre-press and Solvent Extraction Unit: Designed specifically for large-scale, industrial production. It first uses a screw press to remove the bulk of the oil, and then employs solvents (such as hexane) to extract residual oil from the meal, achieving the highest possible yield and operational efficiency.

III. How to Choose the Right Oil Press Machine: Seven Key Factors Before Purchase

Selecting the appropriate oil press machine is a pivotal step that dictates the success of your oil processing business. Before engaging with manufacturers, you must clearly define the following seven core criteria based on your business model and raw material characteristics:

-

Raw Material Type: Confirm the primary oilseeds you will be pressing. For materials like peanuts or rapeseed, a Screw Press is typically recommended; if your focus is sesame, walnuts, or premium olive oil, a Hydraulic Cold Press is better suited. Palm fruit requires specialized Palm Oil Pressing equipment.

-

Capacity Demand: You must specify the required throughput—how many raw materials you plan to process per hour or per day (tons/hour or kg/day). This directly determines the machine’s model and power rating, serving as the benchmark for distinguishing between small household, medium commercial, and large industrial scales.

-

Pressing Method: Do you require:

-

Cold Pressing: Preserves oil flavor and nutrients but yields slightly less, suitable for premium edible oils.

-

Hot Pressing: Maximizes oil yield and improves stability, suitable for general-purpose cooking oils.

-

-

Oil Yield and Residual Oil: These are the key performance indicators (KPIs) for the equipment. An excellent screw press should achieve high yield with an acceptable level of residual oil; if maximum yield is critical, you must consider the Pre-press and Solvent Extraction combination.

-

Energy Consumption and Maintenance Cost: For large equipment, focus on the energy consumption of the motor and heating system. Simultaneously, inquire about the wear-and-tear lifespan and replacement costs for key parts (like press screws and pressing bars).

-

Machine Material: Especially for edible oils, it is crucial that parts in contact with the oil—such as the feed inlet, pressing cage inner walls, and oil outlet—are made of food-grade Stainless Steel to ensure hygiene and product safety.

-

Automation and Certification: Consider the level of automation you need (continuous feeding, automatic temperature control). Crucially, ensure the equipment carries internationally recognized ISO Quality Management and CE Safety Certifications to meet export or local regulatory requirements.

IV. How to Find Oil Press Machine Suppliers in China?

There are multiple ways to find wholesalers of oil press machines and related products in China, as follows:

-

- Google Search Enter keywords like “China oil press machine suppliers” or “industrial oil expeller manufacturer” to quickly screen top suppliers and check their official websites, technical specifications, and customer reviews.

-

- Industry Trade Exhibitions Attend major domestic and international oil processing and grain machinery exhibitions (e.g., China International Oils & Fats and Grains Expo) to communicate with suppliers face-to-face, understand product performance intuitively, and establish cooperation.

-

- Alibaba.com As a major cross-border B2B platform, enter keywords to find a large number of suppliers and communicate online regarding quotations, Minimum Order Quantities (MOQ), and customization needs (such as specifications for palm oil presses).

-

- 1688.com (China Domestic Wholesale Platform) This platform is primarily for buyers within mainland China and often offers the most competitive direct-from-factory prices. However, it is important to note that the site operates primarily in Chinese and does not directly support international shipping or English-language services.

-

- made-in-china.com Filter oil press manufacturers by equipment category (Screw Press, Hydraulic Press) or location, and check quality inspection reports and export qualifications to effectively reduce procurement risks.

-

- Main Chinese Oil Press Machine Bases Major manufacturing bases are concentrated in:

Henan (Zhengzhou, Xinxiang): Focuses on large-scale, continuous oil processing equipment.

handong (Jinan, Qingdao): Features a mix of medium-sized and automated oil refining equipment.

Sichuan/Chongqing: Traditional manufacturing hub, often specializing in small-scale and specialty oil presses.

-

- Procurement Agent Hire a procurement agency like IMEXsourcing to accurately connect with manufacturers according to specific needs (e.g., capacity, raw material type). IMEXsourcing can provide 1688.com sourcing agent services, helping you navigate the language barrier, secure the best factory pricing, and assist with order tracking, equipment quality inspections, and logistics arrangements.

V. What are the Production Bases of Oil Press Machines?

-

- Zhengzhou/Xinxiang, Henan: Known as the “Capital of China’s Oil Machinery,” this region features a highly concentrated industrial cluster for manufacturing large-scale complete oil processing plants, encompassing the full value chain from design and manufacturing to installation and commissioning. Its main products include large-scale continuous screw pre-press machines, solvent extraction equipment, and complete oil refining units. This area is specialized in handling materials like soybeans, rapeseeds, cottonseed, and large-volume palm oil. The base is recognized for its strong technical capabilities and high level of equipment automation, making it suitable for large industrial oil mill projects and international engineering contracts.

-

- Jinan/Qingdao, Shandong: Manufacturers in this area focus on small-to-medium scale, multi-functional, and cost-effective oil pressing equipment. Their product line is extensive, covering household cold/hot presses, commercial hydraulic presses, and specialized equipment for local oil workshops. The Shandong base excels in the application of food-grade stainless steel and ease of operation. Their products offer high flexibility, catering primarily to the bulk procurement needs of small and medium-sized food processing enterprises and domestic/international distributors.

-

- Chengdu/Chongqing, Sichuan: As a traditional oil machinery manufacturing hub in Western China, manufacturers here specialize in high-precision, high-yield hydraulic oil press machines and equipment tailored for specialty oilseeds (such as sesame, walnuts, and tea seed). Their products are known for high pressing purity and superior raw material preservation, making them ideal for producing premium cold-pressed oils and local specialty oil products. This base meets the demands of professional oil mills and high-end food markets with stringent requirements for oil flavor and quality.

VI. Major Domestic Manufacturers of Oil Press Machines in China

1.Anyang Best Complete Machinery Engineering Co., Ltd

Anyang Best Complete Machinery Engineering Co., Ltd (ABC Machinery) is a leading Chinese manufacturer and supplier of oil press machines. Merged in 2014 from GEMCO and KMEC, it leverages the combined strengths of both entities to excel in designing and manufacturing high-quality, efficient screw oil press machinery, backed by an experienced team of engineers and fabricators.

2.Zhengzhou Dingsheng Machine Manufacturing Co., Ltd.

Features spiral oil press machines with various models and capacities, and rich international export experience.

3.Zhengzhou Penguin Grain and Oil Machinery Co., Ltd.

It is a high-tech group enterprise specializing in the production of large-scale spiral oil presses and supporting equipment. It mainly sells spiral oil presses, frying pans, oil filters and other series of products, and has gained wide recognition from customers at home and abroad due to its stable product performance.

4.Anlu Tianxing Grain and Oil Machinery Equipment Co., Ltd.

Established in 2001, it is a high-tech enterprise integrating oil engineering design and equipment manufacturing. It has 66 patents, mainly dealing in oil presses, extruders and other equipment, and has focused on the grain and oil machinery field for more than 20 years with a sound service system.

5. Yongkang Yongguan Food Machinery Co., Ltd.

This factory ranked as the top-selling manufacturer of household oil presses on China’s 1688 platform in 2025.

6. Leling Jinxing Food Machinery Factory

Founded in 2016, the factory focuses on the production and sales of oil presses, material roasting machines, sesame paste machines, and steam engines, while offering value-added services including sample-based processing and OEM/ODM customization.

Research indicates that the manufacturing process for oil press machines is relatively straightforward, resulting in a substantial number of production enterprises operating within China. When navigating this extensive supplier market, the most crucial principle for selecting a partner is to conduct on-site, in-person inspections. The primary goal of this inspection is to thoroughly assess the company’s overall strength and capacity for contract fulfillment (performance capability), which is the vital step for guaranteeing procurement quality and reliable future cooperation.

VII. Precautions for Purchasing Oil Press Machines: A Guide to Informed Decisions 💡

After identifying potential oil press machine suppliers and their products, follow these steps to ensure a smooth and informed procurement process:

- Request Trial Runs or Sample Testing First: Always request a video of the equipment trial run using your specific raw materials or arrange a site visit for testing before placing bulk orders. Check core performance metrics such as whether the actual oil yield meets promised standards, if the residual oil rate is acceptable, the machine’s stability during continuous operation, and if the pressing chamber temperature control is accurate. Also, confirm the machine can process your target raw materials, including palm fruit.

- Evaluate Production and Customization Capabilities: Inquire about the supplier’s daily/monthly production capacity and the overall delivery timeline to ensure they can fulfill bulk or customized orders (e.g., specific capacity requirements, special material grades, or multi-stage pressing configurations). Confirm the consistency of material quality across batches (e.g., the hardness of the crucial press screw steel or the thickness of stainless steel components).

- Consider After-Sales Support and Spare Parts Supply: Confirm the supplier offers comprehensive after-sales guarantees, such as remote diagnostic/on-site maintenance support for equipment failures, replacement of parts damaged during transit, and technical guidance for installation and operation. Clarify the warranty period, stock availability, and long-term supply capability for critical wear-and-tear parts (such as press screws, pressing bars, and sealing rings).

- Calculate Total Cost of Ownership (TCO): Beyond the unit price of the oil press machine itself, include costs for auxiliary equipment (e.g., roasters, filters, refining units), freight charges, on-site installation and commissioning labor costs, and the long-term energy consumption (electricity, fuel) and maintenance expenses. TCO is more critical than the upfront price alone.

- Verify Qualifications and Certifications: Utilize third-party inspection services or platform certifications to check if the supplier holds relevant industry certifications (e.g., ISO 9001 Quality Management, CE/CCC Safety Certifications). Crucially, ensure the materials used in the equipment adhere to international Food Contact Safety Standards, particularly for components that directly touch the oil.

VIII. Choose IMEXsourcing as Your Oil Press Machine Sourcing Partner in China

When procuring high-quality oil press machines and complete oil processing equipment from China, partnering with an experienced and reliable sourcing agent is crucial. IMEXsourcing stands out with a comprehensive service suite to streamline your procurement process and secure exceptional value, with core advantages as follows:

- Extensive Procurement Expertise: With years of experience in the oil machinery sourcing industry, we accurately connect you with top Chinese suppliers. We cover a full range of products, including smart screw presses, high-efficiency hydraulic cold presses, large-scale palm oil press units, solvent extraction equipment, and matching refining systems, meeting your diverse procurement needs for various oilseeds and capacities.

- Bespoke Solutions: We support customization based on your specific requirements, including machine throughput/power, material selection for critical press screws, structural adaptations for specific oilseeds (like high-wax content materials), and industrial automation system configuration (such as precise temperature control, integrated online filtration), perfectly matching your production scale, raw material characteristics, and desired product quality standards.

- Strict Supplier Verification: We conduct comprehensive factory audits on cooperative manufacturers, verifying their production capacity, technical design capabilities, and quality control processes. We ensure suppliers hold relevant certifications (e.g., ISO 9001, CE certification), and products meet domestic and international safety and performance standards (oil yield stability, food-grade stainless steel usage, motor efficiency).

- Professional Negotiation Capabilities: Leveraging industry resources and aggregated procurement volume, we secure the most favorable pricing and terms for you, minimizing procurement costs while avoiding hidden expenses such as substandard materials or delayed delivery.

- Full-Cycle Quality Assurance: We implement a robust end-to-end quality management system, including sample confirmation, production process supervision, and pre-shipment inspection (verifying core indicators such as press screw hardness, pressing cage precision, and completeness of wear parts), ensuring the stable quality of delivered oil press machines and equipment.

IX. Conclusion

The Chinese oil press machine market presents significant opportunities for global buyers. By clearly defining core technical parameters like oil yield, energy consumption, and food-grade material usage, and selecting suitable equipment for various oilseeds (such as palm oil), importers can source high-quality, cost-effective machinery.

Partnering with IMEXsourcing is crucial for ensuring procurement success. We understand the risks associated with precision manufacturing and complex integration in the oil press industry. IMEXsourcing leverages deep knowledge of core production bases like Zhengzhou and Xinxiang, Henan, enabling swift on-site technical audits and production supervision. By verifying a factory’s operational status, financial health, and past delivery records, we help you screen the most stable and technologically capable manufacturers at the source, completely preventing financial losses and procurement disruptions caused by factory issues.