China occupies an unshakable leading position in the global abrasives and abrasive products industry, with its annual output contributing more than 65% of the world’s total. Zhengzhou in Henan Province and Zibo in Shandong Province are the two core production hubs of this sector in China. Zhengzhou, relying on its prominent advantages in superhard material R&D and industrial agglomeration (known as the “Capital of Superhard Materials in China”), has become a global core supply base for superhard abrasive products such as diamond grinding wheels and CBN cutting tools. Its product portfolio covers high-precision industrial-grade superhard abrasives to cost-effective conventional grinding tools, fully meeting the diverse demands of industries like automotive manufacturing, aerospace, and construction worldwide. Zibo, on the other hand, takes advantage of its mature coated abrasive production chain, focusing on the R&D and production of high-performance sanding discs, abrasive belts, and flap discs, and has established a strong reputation in the global coated abrasive market for its stable product quality and efficient supply capabilities.

Chinese abrasives enterprises provide OEM services for over 70% of the world’s well-known international hardware and power tool brands, including but not limited to leading companies such as Bosch, Makita, and DeWalt, as well as a large number of regional professional abrasive tool brands across Europe, North America, and Southeast Asia.

Notably, China’s abrasives and abrasive products industry boasts a highly complete industrial chain, with seamless collaboration among all links: from the R&D and production of raw materials (aluminum oxide, silicon carbide, synthetic diamonds, etc.), the manufacturing of abrasive molds, the pressing and sintering of bonded abrasives, to the coating and processing of coated abrasives, and the final packaging of finished products.

II. Multifunctional Advantages: Why Chinese Angle Grinder Grinding Wheels Stand Out

In recent years, China’s angle grinder grinding wheel industry has developed rapidly, gaining distinct competitiveness in technology, cost, and market adaptation. Here are the key advantages of Chinese angle grinder grinding wheels:

III. Key Specifications & Parameters of Angle Grinder Wheels

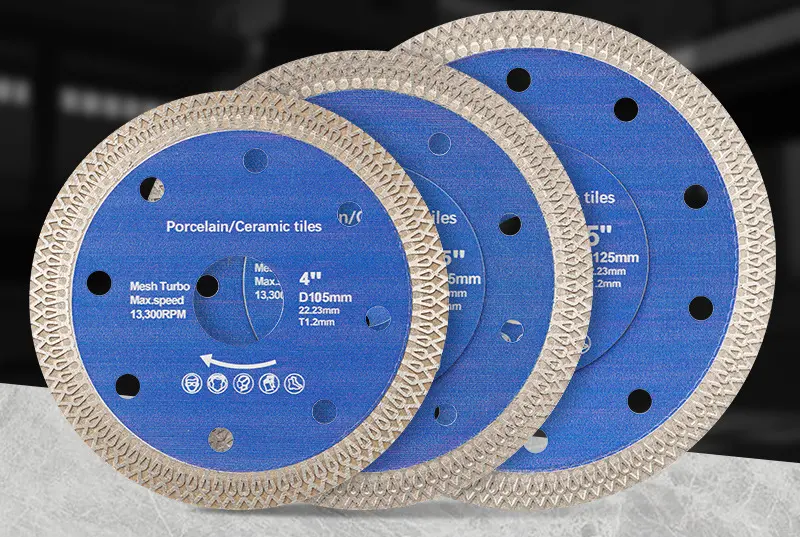

The specifications of angle grinder wheels determine compatibility, safety and performance, and should be selected based on the grinder model and application. Key information is as follows:

1. Basic Specifications (Compatibility Key)

-

- Outer Diameter: 4-inch (100mm) / 4.5-inch (115mm) for household/small grinders; 5-6 inches for industrial ones. Must match the grinder’s max compatible diameter to avoid hazards.

- Bore Diameter: 16mm for 4-4.5-inch wheels (fits household grinder flanges); 20-25.4mm for industrial wheels. Mismatch causes vibration.

- Thickness: 0.8-2mm for cutting wheels (thinner for metal, thicker for stone); 8-20mm for grinding wheels (thicker for flap discs, thinner for wire wheels).

2. Performance Parameters (Effect Key)

-

- Abrasive Material: Aluminum oxide for metal (cutting/flap discs); silicon carbide for stone/glass; diamond for super-hard materials (stone/concrete); steel wire for rust removal.

- Grit Size: 40-80 grit for rough grinding/rust removal; 100-180 grit for fine grinding; 200-240 grit for ultra-fine finishing. Choose based on operation stage.

- Bond Type: Resin bond for cutting (high-speed impact-resistant); vitrified bond for precision grinding (heat-resistant); metal bond for super-hard processing (wear-resistant, 3-5x longer life).

3. Compatibility Parameters (Safety Key)

-

- Max Operating Speed: 12,200-13,300 r/min for 4-4.5-inch resin cutting wheels. Must be ≥ the grinder’s no-load speed to prevent bursting.

- Recommended Material: Follow the label (e.g., “metal-only” wheels can’t cut stone). Cross-material use causes failure.

4. 3-Step Selection

-

- Confirm basic specs (outer diameter + bore diameter);

- Choose performance params (abrasive + grit + bond); 3. Verify safety params (speed + material).

IV. Industrial Clusters: Where to Find Carbon Fiber Manufacturers in China

China’s angle grinder wheel industry has formed distinct regional industrial clusters. Each cluster focuses on different types of wheel production based on advantages in resources, technology, or market access, serving as core regions to find high-quality manufacturers:

- Zhengzhou-Xuchang Cluster (Henan Province): The largest abrasive and abrasive product industrial base in China, with over 300 wheel-related enterprises (e.g., Baige Abrasives). It benefits from sufficient local supply of aluminum oxide abrasives, focusing on mid-to-high-end metal cutting discs and flap discs. Its products offer high cost-performance, covering household and industrial-grade angle grinder wheel needs.

- Foshan-Zhongshan Cluster (Guangdong Province): Relying on the Pearl River Delta manufacturing market, it is dominated by small and medium-sized customized wheel enterprises. Specializing in resin-bonded cutting discs and wood-specific sanding discs, it has fast response speeds, suitable for small-batch customization needs in home decoration and hardware processing scenarios.

- Zibo Cluster (Shandong Province): With silicon carbide abrasive as its core advantage, it focuses on producing diamond wheels for stone cutting and concrete grinding discs. Closely linked to the local stone processing industry, its products have excellent wear resistance, adapting to high-intensity operations of industrial-grade angle grinders.

- Suzhou-Wuxi Cluster (Jiangsu Province): Focusing on R&D and production of precision wheels, enterprises mostly support high-end equipment manufacturing needs. Specializing in ultra-thin metal cutting discs and high-precision elastic grinding discs, it has a high technical threshold, suitable for scenarios requiring high cutting precision and surface finish (e.g., auto sheet metal processing).

V. Domestic Major Manufacturers (Leading Enterprises)

The rapid development of China’s angle grinder wheel industry is driven by a group of key companies with core technologies and large-scale production capabilities. These enterprises specialize in different segments, collectively forming the backbone of China’s grinding wheel sector.

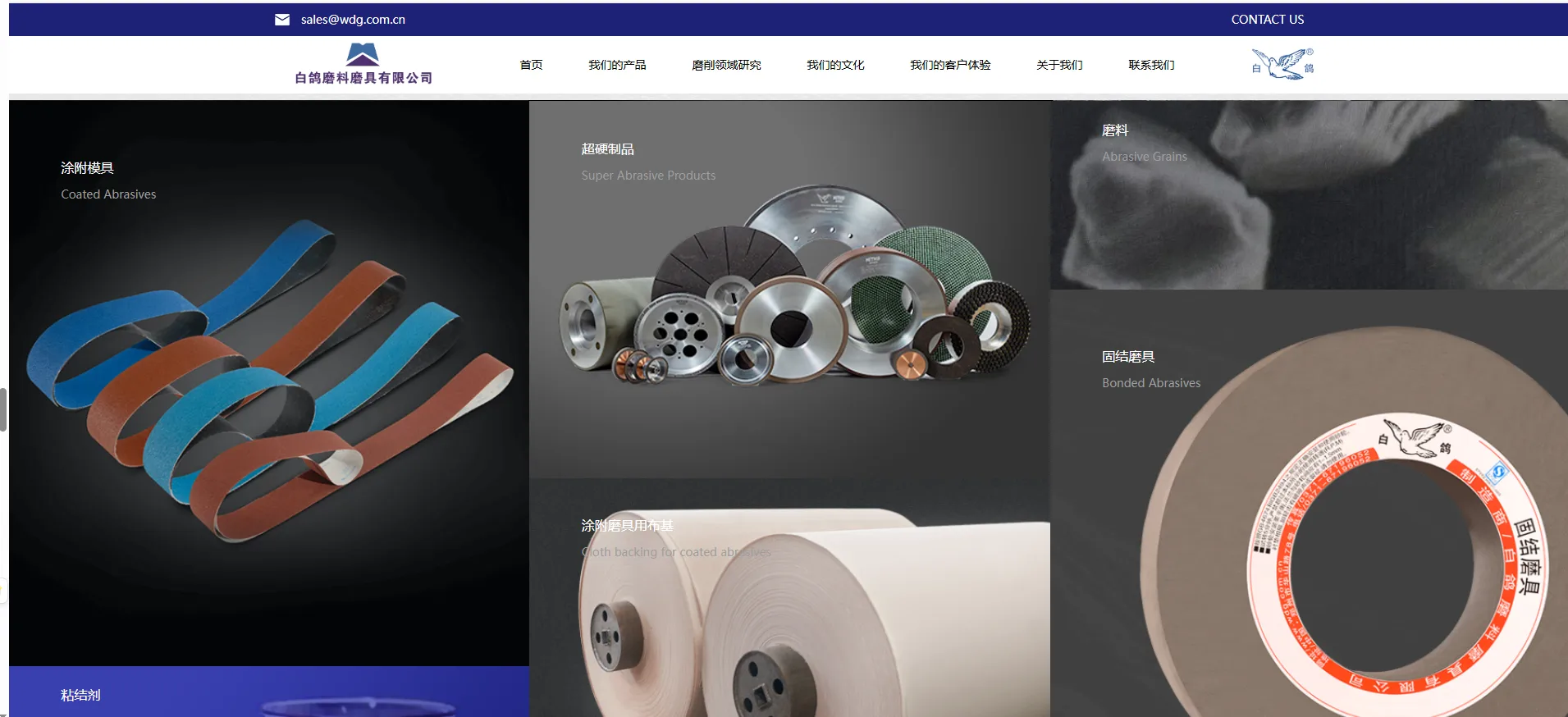

- Baige Abrasives Co., Ltd.

As the leading enterprise in the Zhengzhou-Xuchang industrial cluster (Henan Province), Baige Abrasives, formerly China No.2 Grinding Wheel Factory, has been deeply engaged in the industry for nearly 70 years and owns comprehensive upstream and downstream industrial chain resources for abrasives and abrasive products. Focusing on R&D of mid-to-high-end angle grinder wheels, the company specializes in aluminum oxide metal cutting discs, flap discs, and super-hard abrasives. It has jointly undertaken provincial key projects such as “high-end super-hard abrasives for new energy vehicle key components” with Henan University of Technology, breaking through the “bottleneck” technology in gear grinding. Its products cover household and industrial scenarios, and have become core suppliers for hardware processing enterprises at home and abroad due to stable quality.

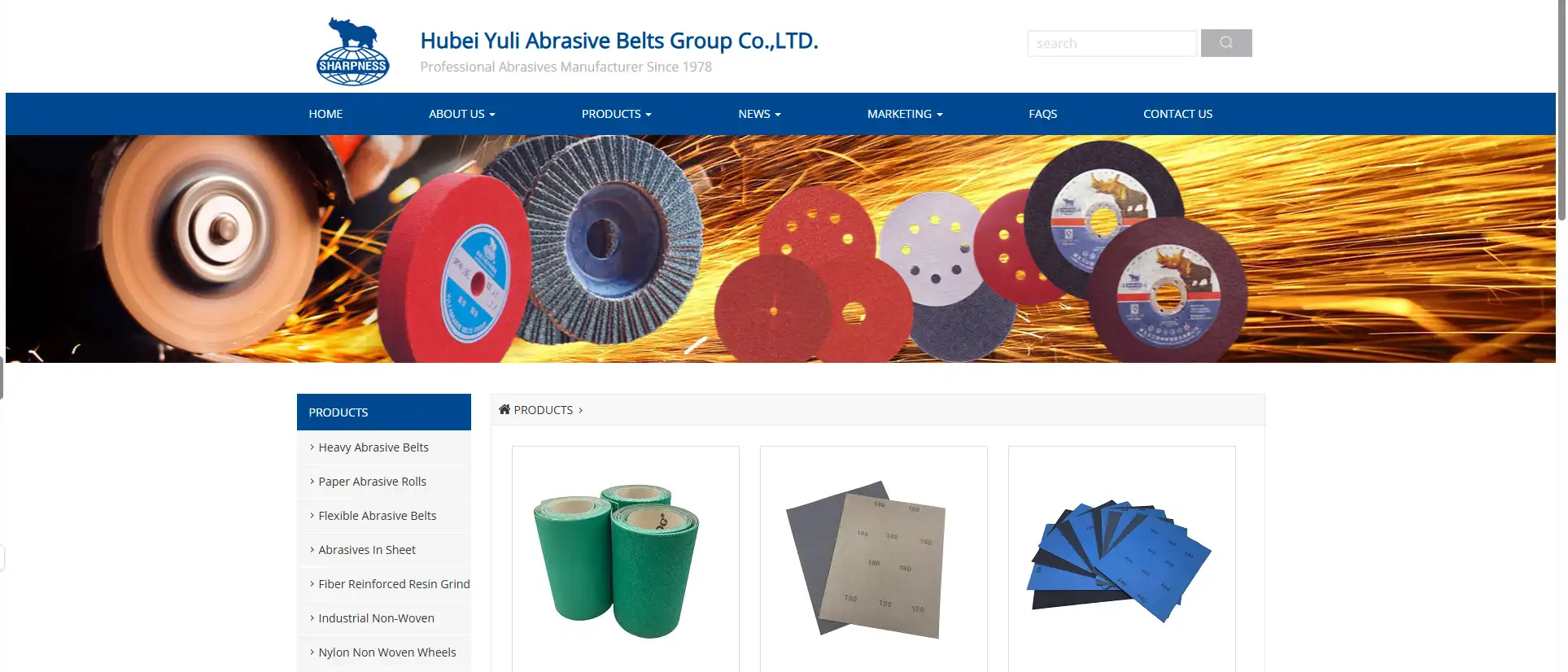

- Hubei Yuli Abrasive Belts Group Co.,LTD.

Rooted in the Sandcloth Town of Tongcheng (Hubei Province), Yuli Group is a leading enterprise in the coated abrasive field, leading the town to form a grinding supply chain platform with “complete products and fast delivery”. The company has a rich product line of angle grinder wheels, including resin cutting discs, abrasive cloth flap wheels, and fiber discs. Its flagship products such as silicon carbide water sandpaper for automobiles are renowned for high wear resistance, widely used in metal weld grinding and rust removal scenarios. With an annual output value exceeding 100 million yuan, its products are exported to Europe, America, and Southeast Asia.

- Guangdong Chuanghui Industrial Co., Ltd.

Belonging to the Foshan-Zhongshan industrial cluster (Guangdong Province), Chuanghui Industrial takes resin-bonded grinding wheels as its core advantage, focusing on the production of fiber-reinforced resin cutting discs and other angle grinder accessories. Relying on the Pearl River Delta manufacturing market, the company specializes in small-batch customization services, with products suitable for home decoration and hardware processing scenarios. Its “Golden Diamond” brand cutting discs have passed the inspection by Qingdao Municipal Administration for Market Regulation, showing outstanding performance in cutting precision and durability, and are favored by regional small and medium-sized processing enterprises.

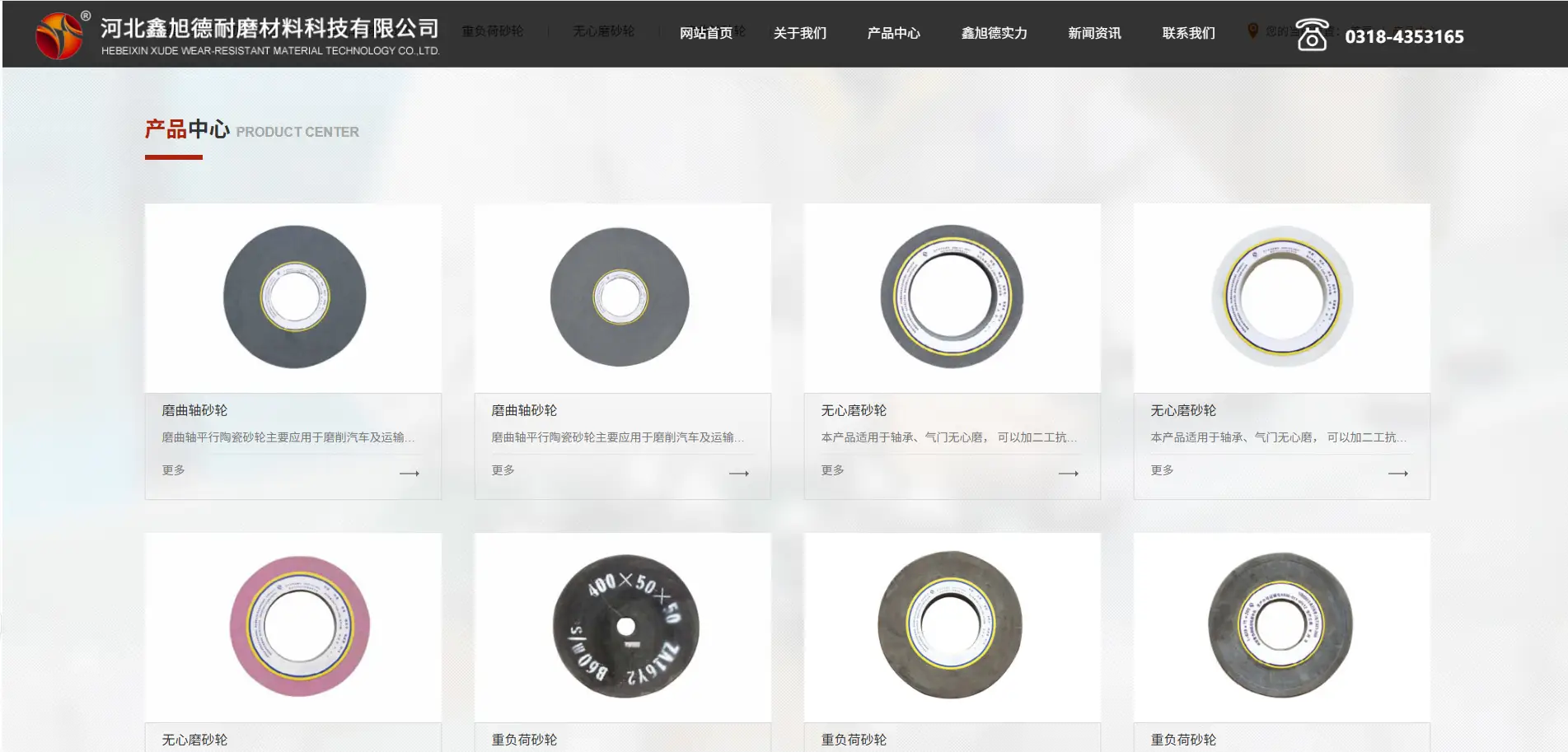

- Hebei Xinxude Wear-Resistant Materials Technology Co., Ltd.

The company was founded in 2010, and it specializes in manufacturing three categories of grinding wheel products in various specifications: large-diameter fiber-reinforced cutting wheels, roll grinding wheels, and heavy-duty billet dressing grinding wheels.

VI. Relevant Certification Requirements

Exporting angle grinder grinding wheels requires different certification requirements in different regions. Here are the certification details for major regions:

- European Union (EU)

CE Certification: A mandatory pass for entering the EU market. Angle grinder grinding wheels must comply with requirements of the Machinery Directive (MD 2006/42/EC), Low Voltage Directive (LVD 2014/35/EU), and Electromagnetic Compatibility Directive (EMC 2014/30/EU). The specific testing standard is the EN 60745 series, such as EN 60745-2-3. This standard specifies requirements for mechanical safety (e.g., the protective cover must withstand an impact force of 150 joules without breaking, and the spindle locking system must prevent accidental startup when replacing grinding wheels) and electrical safety (e.g., insulating materials must pass a 1000V high-voltage test, and a double insulation structure is required). In addition, compliance with the RoHS Directive is necessary to restrict the use of hazardous substances such as lead, mercury, cadmium, and hexavalent chromium.

- United States (US)

UL Certification: Power tools must obtain UL certification to ensure electrical safety. Standards such as UL 60745 or UL 62841-1 cover test items including impact resistance, electric shock prevention, and overheat protection.

FCC Certification: If angle grinder grinding wheels have wireless or electronic functions, FCC ID certification is required to meet electromagnetic compatibility requirements.

CPSC Certification: Focuses on preventing child injuries, such as checking for choking hazards from small parts.

- Russia

CUTR Certification: Exporting angle grinder grinding wheels to Russia must comply with relevant requirements of CUTR Certification, and an EAC Conformity Certificate is usually required. The certification must be issued by a certification body registered with the Customs Union for unified certification. For applicants that are not enterprises in the Eurasian Economic Union (EAEU), they must entrust an importer or agent within the Union as the application entity. Document requirements include Russian-language product manuals, test reports issued by EAEU-accredited laboratories, and risk analysis reports. Certified products should be affixed with the EAC mark.

VII. Precautions for Purchasing: Making an Informed Decision

After identifying potential Chinese angle grinder wheel suppliers and their products, follow these steps to ensure a successful purchase:

1.Prioritize Small-Batch Purchases or Samples First

Before placing a large-order, it is recommended to procure a small batch or samples first. Conduct hands-on tests to evaluate the grinding wheel’s quality and specification consistency—for example, test the cutting efficiency and durability of metal cutting discs (number of consecutive metal cuts) and check abrasive shedding of grinding discs. Ensure the product meets your technical requirements (e.g., bore diameter, speed compatibility).

2.Assess Supplier Production Capacity and Supply Chain Stability

A supplier’s production capacity is critical for meeting order demands, especially for large-volume purchases. Inquire about their monthly output, supply channels for core raw materials (e.g., aluminum oxide, diamond abrasives), and delivery timelines for regular orders. Manufacturers with large-scale production capabilities and stable abrasive procurement channels are more capable of handling orders efficiently and avoiding delays.

3.Clearly Define Your Application Scenario Needs

Clearly inform the supplier of the specific application scenario for the grinding wheel: is it for home decoration metal cutting, industrial stone processing, or wood grinding? Different scenarios have significantly different requirements for grinding wheel parameters—for example, ultra-thin resin cutting discs (0.8-1.2mm) are needed for metal cutting, and diamond grinding blocks for concrete grinding. Clear needs ensure accurate matching of product models and avoid wrong purchases.

4.Focus on Technical Support and Customization Services

A reliable supplier should provide technical support, such as recommending suitable grinding wheel specifications based on the angle grinder model, or offering customization services for special scenarios (e.g., high-precision metal chamfering). Confirm whether their technical team can assist in solving problems during use (e.g., grinding wheel installation deviation) and whether they support specification customization (e.g., non-standard bore diameter, special grit size).

5.Comprehensively Calculate Total Cost

Beyond the unit price, include end-to-end costs: domestic transportation fees, export customs declaration fees, international shipping and insurance, as well as import duties, customs clearance fees in the destination country, and potential costs for third-party quality inspections (e.g., grinding wheel speed testing, safety performance testing). Avoid budget overruns due to omitted costs.

6.Perform Supplier Due Diligence

Verify the supplier’s qualifications and factory conditions through third-party audit institutions. Request quality management system certifications (e.g., ISO 9001) and product safety test reports (e.g., EN 60745-2-3 test report for EU CE certification). If possible, ask the supplier for cooperation cases or recommendation letters from other international buyers to verify their credibility.

VIII. Choose IMEXsourcing Partner for Angle Grinder Wheels in China

When it comes to procuring high-quality angle grinder wheels from China, partnering with an experienced and reliable IMEXsourcing agent is paramount. A good agent offers a comprehensive suite of services designed to streamline your acquisition process and secure exceptional value. Here are compelling reasons to select an IMEXsourcing partner for your next angle grinder wheel purchase:

1.Extensive Procurement Expertise

A professional IMEXsourcing agent has long-standing experience in the angle grinder wheel procurement sector, enabling them to proficiently screen and connect with high-quality Chinese wheel suppliers covering the full product range—including metal cutting discs, diamond grinding blocks, and flap discs. Leveraging deep market insights, they can quickly match suppliers that meet “specific specifications (e.g., 4.5-inch/16mm bore diameter)” and “scenario needs (e.g., industrial stone processing, home decoration rust removal)”, avoiding the risk of wrong selection caused by information gaps.

2.Bespoke Design Solutions

A great agent understands the diverse needs of different clients—for example, automotive manufacturing requires “ultra-thin 0.8mm metal cutting discs” to reduce material waste, while woodworking enterprises need “dust-reducing sanding discs” to improve working conditions. They can assist clients in proposing customization requirements to suppliers, and follow up on product design (e.g., abrasive grit adjustment, bond type optimization) throughout the process, ensuring the final grinding wheel perfectly aligns with actual production or application needs.

3.Thorough Supplier Verification

The commitment to quality begins with rigorous supplier screening. A professional IMEXsourcing agent conducts comprehensive factory verifications for all potential grinding wheel manufacturers, including verifying monthly production capacity (to ensure delivery capability for large orders), reviewing abrasive procurement channels (e.g., quality stability of aluminum oxide and diamond), inspecting quality control processes (e.g., speed testing, wear resistance testing), and confirming compliance with industry standards and legal requirements such as ISO 9001 and CE certification (EN 60745-2-3 standard), eliminating risks of non-compliant supplier qualifications from the source.

4.Expert Price Negotiation

An IMEXsourcing agent has rich industry negotiation experience and is familiar with the cost structure of angle grinder wheels (e.g., abrasive price fluctuations, production process costs). They can negotiate the most favorable purchasing prices and terms (e.g., payment period, minimum order quantity) with leading domestic grinding wheel manufacturers. Especially for large-volume purchases (e.g., annual demand of over 100,000 pieces), they can effectively reduce unit procurement costs and maximize the client’s return on investment.

5.Stringent Quality Assurance

A professional agent implements a robust quality management framework covering the entire procurement cycle: in the early stage, they assist clients in defining quality standards (e.g., metal cutting discs can cut metal continuously for ≥50 times without breaking, sanding disc abrasive shedding rate ≤1%); during production, they conduct factory inspections to supervise key links such as abrasive proportioning and molding processes; before shipment, they perform sampling tests (e.g., maximum speed testing, bore diameter accuracy measurement) to ensure the performance and safety of each batch of grinding wheel products, avoiding return and exchange losses caused by quality issues.

IX. Conclusion

In conclusion, the Chinese angle grinder wheel market offers abundant opportunities for global buyers. By gaining in-depth knowledge of product types (such as metal cutting discs, diamond grinding blocks, and flap discs), clarifying technical specifications (outer diameter, bore diameter, abrasive material, etc.), and following a structured procurement process (sample testing, supplier verification, total cost calculation), importers can source high-quality, cost-effective grinding wheel products to meet diverse application needs—including home decoration, industrial processing, and stone treatment.

Furthermore, partnering with reputable suppliers and conducting comprehensive due diligence (such as factory capacity verification and quality management system certification review) not only improves procurement efficiency but also effectively mitigates potential risks in international trade (e.g., delivery delays, substandard quality). IMEXsourcing possesses professional advantages in the angle grinder wheel sector, with extensive successful experiences in grinding wheel export coordination and quality inspection, and can provide reliable support for buyers. This strategic procurement approach not only enhances purchasing value but also helps build long-term stable cooperative relationships, ultimately laying a foundation for enterprises to improve profitability and market competitiveness.