When you are thinking about buying electric guitars for your business—such as those used for instrument retail, music training school teaching, or stage performances—finding the right products in the global market can be a complicated task. As a core global manufacturing base for electric guitars, China offers a wide range of electric guitars, from cost-effective entry-level practice models to well-crafted professional performance models. This guide will be an indispensable resource for you. It breaks down the key steps of purchasing these instruments, from understanding product types to inspecting suppliers and ensuring compliance.

In the form of a procurement guide, this article covers everything you need to know to make an informed decision and successfully import electric guitars from China, including product types, core advantages, technical parameters, major production bases, leading manufacturers, certification requirements, and key purchasing considerations.

Inhaltsübersicht

Umschalten aufI. Product Type Introduction: A World of Electric Guitars

After years of development, electric guitars have evolved into a wide variety of types to meet different musical styles and playing needs. Below is a detailed introduction to common electric guitar product categories:

- Classification by Body Structure

- Solid Body Electric Guitar: Solid body electric guitars are the most common, accounting for about 95% of the market share. The guitar body is made of a single piece of solid wood with no hollow parts, making the manufacturing process relatively simple and allowing for quick production of various styles. Without acoustic limitations, the body can be designed in diverse shapes—from simple classic styles with a neck and pickups to bold, unconventional ones. This design avoids feedback issues at high volumes and high gain, delivering smooth sustain and tight low-frequency performance during playing, which is especially suitable for high-distortion rock music. Fender’s Stratocaster (ST type), Telecaster (TELE type), and Gibson’s Les Paul (LP type) all fall into this category.

-

- Hollow Body Electric Guitar: Hollow body electric guitars have a thick body, composed of a top panel, side panels, and back panel with a hollow interior. The top and back panels are smoothly curved in an arch shape, and F-shaped sound holes are usually cut on the left and right sides of the front. This design enables the guitar to produce rich, full sounds with excellent resonance, featuring warm and mellow tones that are highly favored by jazz guitarists. However, hollow body electric guitars have relatively short sustain and are prone to feedback issues due to signal reflection when connected to an amplifier, so more careful volume control is required.

- Semi-Hollow Body Electric Guitar: The weight of a semi-hollow body electric guitar falls between that of solid body and hollow body electric guitars, and its tone combines the sharpness of solid body guitars and the warmth of hollow body guitars. Its body looks like a slightly thinned hollow body guitar, with F-holes on the top panel. The interior is not fully hollow—instead, a piece of wood (called a center block) is placed in the middle of the body. This design reduces the possibility of feedback and offers flexible tone performance, suitable for various musical styles. Whether it’s rock or blues, it helps players achieve satisfying sounds, making it a top choice for many musicians.

- Chambered Body Electric Guitar: The main focus of chambered body electric guitars is to reduce the overall weight of the guitar, ensuring comfort after long hours of playing. Weight reduction is usually achieved by hollowing out parts of the wood while keeping the exterior sealed. Although this may slightly affect tone resonance, the performance is still close to that of solid body guitars, which is favored by some players. It is a good option for musicians who want to reduce weight without sacrificing tone.

-

Classification by Classic Body Styles

- Stratocaster (ST Type): Launched by Fender in the 1950s, it established the basic shape of modern electric guitars. It features a smooth double-cutaway body design, bright tones, and is mostly equipped with single-coil pickups, with outstanding high-frequency response. It is an iconic instrument for pop, funk, and other styles.

- Telecaster (TELE Type): Also launched by Fender, it is one of the first successfully mass-produced solid body electric guitars. It has a simple single-cutaway structure and bright tones, and dominates in country music.

- Les Paul (LP Type): Released by Gibson in 1952, it has a relatively thick body and is equipped with humbucker pickups, producing warm and rich tones. It has become the top choice for hard rock and heavy metal.

- SG Type: Produced by Gibson, its iconic double-pointed cutaway design improves the playing experience on the higher frets, with more balanced and bright tones. It is often used by metal guitarists.

- ES Type: As a representative of semi-hollow body guitars, it combines the resonance of acoustic guitars and the amplification characteristics of electric guitars, and is highly respected in the jazz field.

-

Classification by Pickup Configuration

-

- Single Coil Pickup Electric Guitar: It captures string vibrations through a single magnetic coil, producing clear and bright sounds with excellent high-frequency response—just like the classic tone of Fender Stratocaster. However, single-coil pickups have a 60Hz AC hum issue.

-

- Humbucker Pickup Electric Guitar: It uses two coils wound in opposite directions, which effectively eliminates noise and delivers richer, warmer tones with prominent mid-low frequencies. It is suitable for rock, metal, and other styles. For example, Gibson Les Paul is often equipped with this type of pickup.

-

- Hybrid Pickup Electric Guitar: Modern electric guitars often use hybrid configurations, such as “S-S-H” (single-coil at neck and middle + humbucker at bridge) or “H-S-H” combinations, to meet diverse tone needs. The pickup at the bridge tends to have bright and sharp tones, suitable for lead playing; the pickup at the neck produces mellow and warm tones, more suitable for rhythm playing.

II. Multifunctional Advantages: Why Chinese Electric Guitars Stand Out

The world’s main electric guitar production hubs include countries like China, the United States, Japan, and South Korea.

- The U.S. is home to famous brands such as Fender and Gibson. Their high-end products are highly respected in the professional music field.

- Japan’s guitar brands, like Ibanez and ESP, are known for excellent craftsmanship and attention to detail, and perform well in the mid-to-high-end market.

- Some South Korean brands hold a certain market share with cost-effective products.

China has significant advantages in electric guitar production:

1. Complete Industrial Chain for Electric Guitars

China has a large number of musical instrument manufacturers and accessory processing enterprises. All links—from wood and accessory supply to finished product assembly—work closely together.

Just one town in China produces 30% of the world’s electric guitars. Enterprises can easily obtain all types of raw materials and accessories, which reduces procurement costs and transportation time, and improves production efficiency.

For example, the wood needed to make electric guitars can be sourced from North America and Africa, and musical accessories from places like Zhejiang and Guangdong in China are gathered locally—enabling efficient production.

Just one town in China produces 30% of the world’s electric guitars. Enterprises can easily obtain all types of raw materials and accessories, which reduces procurement costs and transportation time, and improves production efficiency.

For example, the wood needed to make electric guitars can be sourced from North America and Africa, and musical accessories from places like Zhejiang and Guangdong in China are gathered locally—enabling efficient production.

2. Cost Advantage

Labor costs make up a large part of the total cost of electric guitars. Compared with other production hubs, some regions in China have an advantage in labor costs.

In addition, large-scale production lowers raw material procurement costs, further reducing overall production costs. This makes Chinese electric guitars more price-competitive and suitable for large-scale market supply.

In addition, large-scale production lowers raw material procurement costs, further reducing overall production costs. This makes Chinese electric guitars more price-competitive and suitable for large-scale market supply.

3. Industrial Cluster Effect

Many electric guitar manufacturers and supporting enterprises are concentrated in the Tangwu Town Electric Guitar Base in China, forming an industrial cluster.

This concentration enables fast exchange and sharing of information and technology, and promotes mutual learning and competition among enterprises.

Enterprises can keep up with the latest industry trends, technological innovations, and changes in market demand—speeding up product innovation and technological upgrades. At the same time, industrial clusters attract a large number of professional talents, providing enterprises with sufficient labor and technical support.

This concentration enables fast exchange and sharing of information and technology, and promotes mutual learning and competition among enterprises.

Enterprises can keep up with the latest industry trends, technological innovations, and changes in market demand—speeding up product innovation and technological upgrades. At the same time, industrial clusters attract a large number of professional talents, providing enterprises with sufficient labor and technical support.

4. Technological Innovation and Upgrading

Chinese electric guitar enterprises actively invest in technological research and development to drive innovation in production technology.

On the production side, smart workshops in Chinese factories have introduced CNC machines and robotic arms, replacing traditional manual processes like sanding and body carving.

This intelligent transformation has increased production consistency by 90%, and the product defect rate is close to 0.

For example, EART Musical Instruments has launched fingerboard curve optimization technology. Through 3D modeling and ergonomic analysis, it lowers string height and uses a gradual curve transition—improving playing comfort and intonation stability.

On the production side, smart workshops in Chinese factories have introduced CNC machines and robotic arms, replacing traditional manual processes like sanding and body carving.

This intelligent transformation has increased production consistency by 90%, and the product defect rate is close to 0.

For example, EART Musical Instruments has launched fingerboard curve optimization technology. Through 3D modeling and ergonomic analysis, it lowers string height and uses a gradual curve transition—improving playing comfort and intonation stability.

III. Main Specifications and Parameters

The specifications and parameters of an electric guitar directly determine its playability, tone, and suitability for different scenarios. Different parameter combinations work for various music styles and playing needs. Below is a clear, easy-to-understand breakdown of core specifications and parameters, with simple explanations for professional terms:

1. Core Body Parameters (Affect Tone, Weight, and Resonance)

1.1 Body Material (Shapes the Basic Tone)

- Common Materials:

- Basswood: Lightweight, with balanced tone and warm mid-low frequencies. Ideal for entry-level guitars or pop/rock styles. Low cost (used in most entry-level Strat-style guitars).

- Maple: Dense and hard, producing bright, sharp high frequencies. Often used as a “top veneer” (e.g., the maple top on Gibson Les Pauls). Full maple bodies are rare (they’re heavy).

- Mahogany: Rich mid-low frequencies, great sustain, and warm, thick tone. Perfect for hard rock/metal (e.g., Gibson Les Paul bodies).

- Alder: Balanced tone—clear highs and tight lows. Combines brightness and warmth. The main material for classic Fender Strat/Tele bodies.

- Note: The effect of body material on tone depends on the pickup. For example, mahogany + humbucker pickups boost thickness, while alder + single-coil pickups enhance brightness.

1.2 Body Structure (Relates to Resonance and Feedback Control)

- Matches the “body type” categories mentioned earlier. Parameters are usually labeled directly:

- Solid Body: Labeled “Solid” (no extra explanation—this is the most common type).

- Semi-Hollow Body: Labeled “Semi-Hollow”. Some add “center block size” (e.g., “Center Block: 50mm”) to reduce feedback.

- Hollow Body: Labeled “Hollow”. May note “sound hole type” (e.g., “F-Holes”—common in jazz guitars).

1.3 Body Weight (Affects Playing Comfort)

- Typical range: 2.5kg – 4kg (varies by material):

- Lightweight (2.5-3kg): Usually basswood/light alder. Good for long standing performances (e.g., stage shows).

- Standard (3-3.5kg): Alder/mahogany. Balances tone and comfort.

- Heavy (3.5-4kg): Full mahogany or maple-veneer guitars. Solid tone but tiring for long playing (e.g., some Les Paul models).

2. Neck and Fingerboard Parameters (Determine Playability and Smoothness)

2.1 Neck Material (Affects Stability and Feel)

- Neck Core: Mostly maple (hard, not easy to warp). Some low-end guitars use basswood. High-end guitars may label “quartersawn maple” (more stable).

- Fingerboard Material:

- Rosewood: Smooth texture, warm feel, and soft high frequencies. The most common fingerboard material (used in most Fender/Gibson guitars).

- Maple: Smooth surface, bright high frequencies. Needs a protective finish (e.g., Fender Telecaster’s “Maple Fingerboard” models).

- Ebony: Dense and hard, with sharp tone and smooth feel. Used in high-end guitars or metal-style guitars (e.g., Schecter, ESP high-end models).

2.2 Neck Shape (Affects Grip—varies by hand size)

- Common types (parameters use simple abbreviations):

- C-Shape: Moderate curve, comfortable grip. Fits most hand sizes (the main shape for classic Fender Strats/Teles).

- V-Shape: V-curved sides. Divided into “Soft V” (gentle curve, good for modern playing) and “Hard V” (steeper curve, good for vintage styles or large hands).

- U-Shape: Thick, like a “baseball bat”. Good for vintage guitars or players who like a solid feel (e.g., some Gibson Les Paul vintage models).

- Oval: Between C-Shape and U-Shape. Balances comfort and solidity (used in some PRS guitars).

2.3 Fingerboard Radius (Affects Comfort—fits chords or fast playing)

- Unit: Inches. Smaller numbers = more curved; larger numbers = flatter.

- Small radius (7.25″-9.5″): More curved. Fingers fit better for chords. Good for rhythm playing or vintage styles (e.g., Fender vintage models use 7.25″).

- Medium radius (10″-12″): Balances chords and single notes. Fits most styles (modern Fender/Gibson models use 9.5″-12″).

- Large radius (14″-16″): Flatter. Good for fast playing, string bending, or metal (e.g., ESP/Jackson guitars use 12″-16″).

2.4 Scale Length (Affects string tension and tuning—fixed by brand)

- Unit: Inches. Common sizes:

- 25.5″: Fender’s standard. Moderate string tension, wide range. Good for pop, rock, fusion (e.g., Strats/Teles).

- 24.75″: Gibson’s standard. Lower string tension—easier to bend strings. Warmer tone. Good for blues, hard rock (e.g., Les Pauls, SGs).

- 24.625″ (or 24.6″): PRS’s unique scale length. Balances tension and feel.

- Short scale (22.75″-24″): Found in travel guitars or kids’ guitars. Low tension—good for small hands.

2.5 Fret Size (Affects tone clarity and durability)

- Common types (labeled as “Gauge” or “Size”):

- Narrow Tall / Medium Narrow: Small contact area, delicate tone. Good for vintage guitars or players who like precise fretting.

- Medium Jumbo: Balances durability and feel. The main size for modern guitars (most modern Fender/Gibson models).

- Jumbo / Extra Jumbo: Thick frets. Less finger pressure needed, good sustain. Perfect for fast playing or metal (e.g., ESP/Jackson guitars).

- Fret Count: Usually 22 frets. Some metal guitars have 24 frets (more high notes, e.g., Schecter C-1). Vintage guitars often have 21 frets (e.g., Fender vintage models).

3. Pickup and Circuit Parameters (Determine Core Tone Style)

3.1 Pickup Type (The most important tone parameter—easy to distinguish)

- Labels show the type directly, with clear tone differences:

- Single Coil: Labeled “Single Coil”. Bright, clear highs. Good for pop, funk, country (e.g., Fender Strat’s “Texas Special” pickups). Drawback: 60Hz hum.

- Humbucker: Labeled “Humbucker”. Thick, rich mid-low frequencies. No obvious hum. Good for rock, metal (e.g., Gibson Les Paul’s “Burstbucker” pickups).

- Piezo: Labeled “Piezo Pickup”. Installed under the bridge. Simulates acoustic guitar tone. Good for “acoustic-electric” needs (e.g., some PRS SE models).

3.2 Pickup Configuration (Labeled as “Neck-Middle-Bridge”—affects tone variety)

- Common setups (directly impact tone options):

- S-S-S (3 single coils): Bright, versatile tone. Good for pop, funk (e.g., standard Fender Strats).

- H-H (2 humbuckers): Thick tone. Good for rock, metal (e.g., Gibson Les Pauls, Schecter C-1s).

- S-S-H (Single-Single-Humbucker): Neck/middle single coils (bright rhythm), bridge humbucker (thick leads). Balances many styles (main setup for modern entry-level guitars).

- H-S-H (Humbucker-Single-Humbucker): Neck/bridge humbuckers (high gain), middle single coil (clean tone). Good for metal + clean switching (e.g., ESP LTD M series).

3.3 Circuit Controls (Affect tone adjustment range)

- Common labels (usually “knobs + switches”):

- Volume Knob: 1-2 knobs. Controls overall volume. Some high-end guitars have a “Push-Pull” switch (switches pickup modes, e.g., “single coil/humbucker”).

- Tone Knob: 1-2 knobs. Controls high-frequency cut (turn clockwise for brightest highs; counterclockwise for darker highs).

- Pickup Selector Switch:

- 3-Way Switch: Common in H-H or basic S-S-S models. Switches pickup combinations (e.g., H-H models: “neck pickup – both pickups – bridge pickup”).

- 5-Way Switch: Common in S-S-S or S-S-H models. More combinations (e.g., S-S-S models: “neck – neck+middle – middle – middle+bridge – bridge”).

4. Hardware Parameters (Affect Durability, Tuning Stability, and Intonation)

4.1 Bridge Type (Determines tuning stability and vibrato function)

- Common types (labels show function directly):

- Fixed Bridge: No vibrato. Simple structure, stable tuning. Good for rhythm guitars or metal guitars (e.g., Gibson Les Paul’s “Tune-O-Matic” bridge, Schecter’s “Fixed Bridge”).

- Tremolo Bridge (Single-Cutaway): Press down to make vibrato. Can’t pull up. Stable structure (e.g., Fender Strat’s “Standard Tremolo”).

- Floyd Rose Bridge (Double-Cutaway): Both up and down vibrato. Good for big techniques (e.g., metal’s “Dive Bomb”). Needs frequent tuning. Guitars with this bridge label “Floyd Rose” or “Double Locking Tremolo”.

4.2 Tuners (Affect tuning stability—also called “machine heads”)

- Key parameter: Usually labeled by brand or type. E.g., “Grover Tuners” (used in Gibsons, stable), “Fender Standard Tuners” (entry-level), “Locking Tuners” (used in high-end or double-cutaway guitars—reduces string slip, faster tuning).

4.3 Nut Material (Affects intonation transfer and durability)

- Common materials:

- Plastic: Used in entry-level guitars. Low cost, average tone transfer.

- Bone: Main material for mid-high-end guitars. Good tone transfer, stable intonation. Needs regular care.

- Graphite: Self-lubricating. Reduces string breakage. Good for tremolo bridges (e.g., some Fender models).

- Titanium: Used in high-end guitars. Hard, excellent transfer. Expensive.

5. Other Auxiliary Parameters (Affect Usage Scenarios and Details)

- Finish Type: Labeled “Finish Type”. E.g., “Polyurethane” (durable, easy to maintain), “Nitrocellulose” (vintage look, good tone transfer but easy to scratch—used in high-end vintage guitars).

- Color: Labeled “Color”. E.g., “Black”, “Sunburst” (Gibson’s classic color), “Olympic White” (Fender’s classic color).

- Output Jack: Labeled “Output Jack”. Usually a “1/4-inch mono jack”. Some acoustic-electric guitars add an “XLR balanced jack” (for professional shows).

- Weight Relief: High-end solid-body guitars may label “Chambered Body” (hollowed inside to reduce weight) or “Lightweight Construction”. Reduces weight without losing tone.

Summary: How to Check Parameters and Buy

- Focus on Core Parameters First: For beginners, start with “neck shape (C-Shape first) + scale length (25.5″ or 24.75″) + pickup configuration (choose based on style: S-S-S/H-H/S-S-H)”. Then check material and hardware brand.

- Where to Find Parameters: Brand websites list full specs under “Specifications”. E-commerce product pages highlight key parameters (e.g., “Mahogany body + humbucker pickups + 24 frets”).

- Don’t Rely Only on Parameters: Guitars with the same parameters can sound/feel different due to brand craftsmanship. Try playing if possible—real feel and tone matter more than numbers.

IV. Industrial Clusters: Where to Find Electric Guitars Manufacturers in China

During its development, China’s electric guitar industry has formed several industrial bases. These bases have their own advantages in production scale, product characteristics, and other aspects, playing an important role in promoting the development of China’s electric guitar industry:

Changle Tangwu Town, Shandong Province:It is an important electric guitar industry base in China, known as the “China Electroacoustic Instrument Industry Base”.

The town has a large number of musical instrument production and accessory processing enterprises. It produces 2 million electric guitars and 5 million sets of accessories every year, accounting for 40% of China’s total electric guitar output and 30% of the global output. Its products are sold to more than 130 countries and regions, with an annual income of over 1 billion yuan.

The industry here started in the 1970s, initially focusing on OEM production. Later, it gradually shifted to developing independent brands and has fostered more than 40 local brands such as “EART”, “Delura” and “Big Tree”.

A complete industrial chain has also been formed locally: all links, from wood and accessory supply to finished product assembly, work closely together.

The industry here started in the 1970s, initially focusing on OEM production. Later, it gradually shifted to developing independent brands and has fostered more than 40 local brands such as “EART”, “Delura” and “Big Tree”.

A complete industrial chain has also been formed locally: all links, from wood and accessory supply to finished product assembly, work closely together.

Guangzhou, Guangdong Province:As an important manufacturing center in southern China, Guangzhou’s electric guitar industry mainly focuses on high-end customization and export.

It has strong technical strength, with many experienced guitar makers and advanced production equipment, which can meet customers’ high requirements for guitar quality and personalization.

In terms of export, Guangzhou has convenient transportation and a complete logistics system, making it easy to ship products to all parts of the world quickly. It holds an important position in the international electric guitar market.

In terms of export, Guangzhou has convenient transportation and a complete logistics system, making it easy to ship products to all parts of the world quickly. It holds an important position in the international electric guitar market.

Tianjin:Tianjin’s electric guitar industry started relatively early and has many long-established musical instrument factories.

These old factories have accumulated rich manufacturing experience and formed mature production processes.

Electric guitars produced in Tianjin are famous for their high cost-performance, meeting the needs of different consumer groups.

Electric guitars produced in Tianjin are famous for their high cost-performance, meeting the needs of different consumer groups.

Shanghai:As an international metropolis, Shanghai has attracted many OEM factories and R&D centers of international brands.

This makes Shanghai take the lead in electric guitar production technology, mainly producing mid-to-high-end electric guitars.

A large number of professional talents gather here, with strong design and innovation capabilities. They can keep up with international trends and launch new products that meet market needs, leading the industry in the design, R&D and production of electric guitars.

A large number of professional talents gather here, with strong design and innovation capabilities. They can keep up with international trends and launch new products that meet market needs, leading the industry in the design, R&D and production of electric guitars.

V. Major Domestic Electric Guitar Manufacturers

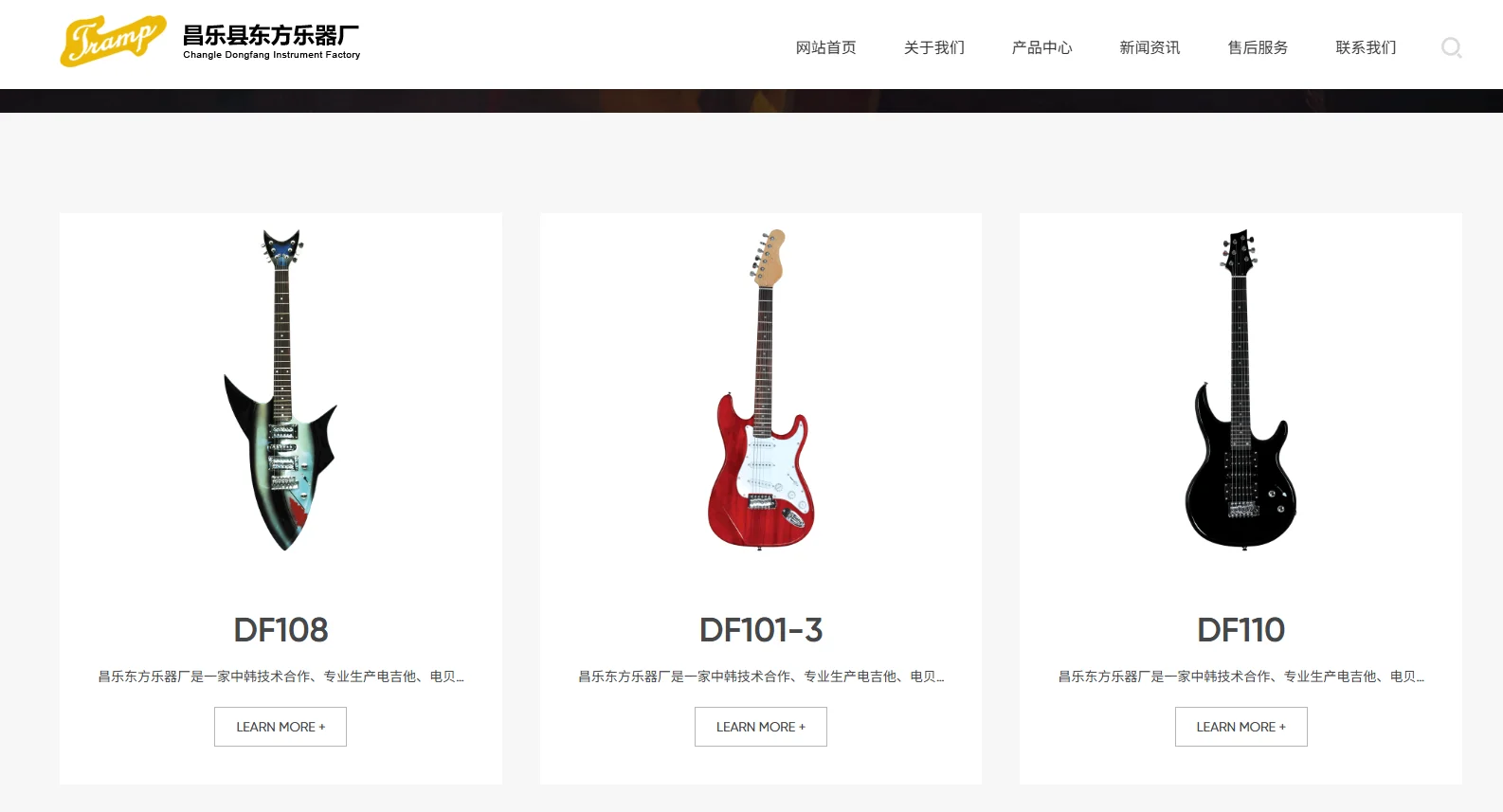

- Changle Dongfang Instrument Factory: https://www.dongfangyueqi.com/ This is a Sino-Korean technical cooperation enterprise, specializing in the production of electric guitars, electric basses, acoustic guitars, and speaker series products. The Tramp-branded electric guitars and electric basses developed by it come in nearly 100 varieties across high, medium, and low grades.

- Shandong EART Musical Instruments Co., Ltd. :https://www.eartmusic.com/ The company’s products are mainly sold to Europe, America, Japan, South Korea, Australia and other countries and regions, and it also undertakes OEM orders.

- Changle Changyunda Musical Instruments Co., Ltd. :The company boasts a large scale, with an annual output of over 200,000 electric guitars. From raw material processing to finished product assembly, tuning and inspection, each guitar goes through nearly 100 production processes. The guitars produced by the company can meet the needs of different customers.

- Changle Mingyu Musical Instruments Co., Ltd. The company has registered its independent brand in the United States and sells its products there. It offers flexible order acceptance and undertakes OEM orders of various batch sizes.

VI. Einschlägige Zertifizierungsanforderungen

The certification requirements for electric guitar exports vary by target market. Below are the certification requirements for major markets and domestic production in China:

1. Certification Requirements for Export to Major Markets

1.1 EU Market

- CE Certification: It is a mandatory “passport” for entering the EU market. As an electronic product, electric guitars must comply with the Low Voltage Directive (LVD), Electromagnetic Compatibility Directive (EMC), and Restriction of Hazardous Substances (RoHS) Directive:

- The LVD applies to electronic products with a rated voltage of 50-1000V AC or 75-1500V DC, ensuring the electrical safety of electric guitars.

- The EMC Directive requires that electromagnetic interference generated by electric guitars be controlled within specified limits, and that the guitars can normally resist a certain level of electromagnetic interference.

- The RoHS Directive restricts electric guitars and their internal electronic components from containing six types of hazardous substances, such as lead, mercury, and cadmium.

- REACH Regulation: It focuses on the registration, evaluation, authorization, and restriction of chemicals, covering the chemical safety of electric guitar accessories and materials.

- Battery and Battery Pack Certification: If an electric guitar is equipped with a built-in battery, it must also comply with the relevant requirements of the EU Battery Directive.

1.2 US Market

- FCC Certification: It is a mandatory certification issued by the U.S. Federal Communications Commission (FCC) for the electromagnetic compatibility (EMC) and radio frequency interference (RFI) of electronic products.

- Electronic components in electric guitars (such as pickups, amplifiers, and tuning devices) generate electromagnetic interference and thus require FCC certification.

- If an electric guitar includes a wireless transmission module (e.g., a wireless guitar system), it must obtain FCC Certification (a formal certification).

- For ordinary electric guitars with only wired interfaces and traditional pickups, they generally comply with the limits of FCC Part 15 Subpart B, and enterprises need to submit a corresponding self-declaration to prove that the guitars do not generate excessive radiation.

1.3 Other Markets

- Japanese Market: Electric guitars generally need to comply with PSE Certification, which ensures the safety of electrical products. PSE Certification is divided into “Specified Electrical Appliances and Materials” (high-risk products) and “Non-Specified Electrical Appliances and Materials” (low-risk products). Electric guitars usually fall into the latter category and need to be labeled with the circular PSE mark.

- Australian Market: Electric guitars must comply with ACMA Certification (administered by the Australian Communications and Media Authority). It mainly covers requirements for electromagnetic compatibility and radio frequencies, ensuring that electric guitars do not interfere with Australia’s communication and electronic equipment.

2. Certification Requirements for Domestic Production in China

- CCC Certification: In accordance with the Administrative Regulations on Compulsory Product Certification, electric guitars must meet the standards of China Compulsory Certification (CCC). It is a key certification to ensure that electric guitars meet basic safety and quality requirements.

- GB/T 31794-2015 Electroacoustic Instruments: This national standard specifies the product classification, requirements, test methods, and inspection rules for electric guitars. It covers the technical performance requirements of electric guitars, including tone, pickups, circuits, structure, appearance, and durability.

- Quality Management System Certification: For example, ISO 9001 Quality Management System Certification can prove that an enterprise has a sound quality management process and capability, enabling effective quality control in all links such as product design, manufacturing, and after-sales service.

VII. Precautions for Purchasing: Making an Informed Decision

Once you have identified potential suppliers and their electric guitar products, follow these steps to ensure a successful purchase:

Start with Samples: Before placing a large order, it is highly recommended to order sample electric guitars. This allows you to conduct a hands-on quality assessment, including checking the guitar’s body craftsmanship (such as wood grain consistency and surface smoothness), component performance (like pickup tone, knob responsiveness, and string stability), and overall playability. Test factors such as fret smoothness, string action, and sound projection across different musical styles.

Assess Supplier Production Capacity: A supplier’s production capacity is critical to determining whether they can meet your needs, especially for bulk orders. Inquire about their monthly/annual output of electric guitars, production line efficiency, and typical delivery timelines for orders of different sizes. A well-experienced manufacturer with mature production lines is more likely to fulfill large orders on time while maintaining consistent product quality.

Define Your Intended Use Clearly: Be specific about your target market and the intended use of the electric guitars. Will they be for beginner players (prioritizing affordability and ease of use)、professional musicians (requiring high-quality tone and stable performance)、or genre-specific needs (such as heavy metal, which may demand high-output pickups and durable hardware)? These specific requirements will determine key features like pickup type, body wood material, hardware quality, and electronic configuration.

Consider After-Sales Support: A reliable electric guitar supplier should offer comprehensive after-sales support, including provision of spare parts (such as strings, pickups, and tuning pegs) and technical assistance (like guidance on maintenance or repair). Inquire about their warranty policy (e.g., coverage period for structural defects or electronic malfunctions) and how they handle issues such as returns, repairs, or component replacements for defective products.

Calculate Total Cost: Don’t just focus on the unit price of electric guitars; account for all additional costs. These include international shipping fees (especially for bulk orders), import duties and customs clearance costs in your target market, local sales taxes, and potential expenses for product modifications (such as custom logos or hardware upgrades) or additional warranty services.

Perform Due Diligence: Verify the supplier’s legitimacy and production conditions using reliable tools. For example, check for “Audited Supplier” certifications on B2B platforms (like Alibaba), or hire third-party inspection services to assess their factory’s production standards, quality control processes, and compliance with industry regulations. Additionally, ask the supplier for references from other international buyers to learn about their past cooperation experiences and product quality feedback.

VIII. Choose IMEXsourcing as Your Sourcing Partner for Electric Guitars in China

When it comes to procuring high-quality electric guitars from China, partnering with an experienced and reliable sourcing agent is paramount. IMEXsourcing stands out as a premier choice, offering a comprehensive suite of services designed to streamline your acquisition process and secure exceptional value. Here are compelling reasons to select IMEXsourcing for your next electric guitar purchase:

Umfassendes Fachwissen im Bereich Beschaffung

IMEXsourcing boasts a profound and long-standing history in the electric guitar sourcing industry, enabling us to proficiently locate and secure a wide array of electric guitars—from beginner models to professional-grade instruments—from highly regarded Chinese suppliers. Our deep market knowledge, honed through years of collaboration with top manufacturers, ensures that we connect you with partners known for their reliability, craftsmanship, and adherence to international quality standards.

Strategic Geographic Advantage

A key differentiator for IMEXsourcing is our unbeatable geographic location: we are merely a 1-hour drive away from Tangwu Town, China’s largest electric guitar production base (located in Changle County, Shandong Province). This proximity allows us to conduct on-site factory visits at short notice, closely monitor production progress in real time, and quickly address any issues that may arise during manufacturing. It also eliminates delays in sample collection and delivery, ensuring you receive product samples faster and can make purchasing decisions more efficiently—an advantage that remote sourcing agents simply cannot match.

Maßgeschneiderte Designlösungen

At IMEXsourcing, we understand that unique market needs or brand identities often demand tailored electric guitar solutions. Whether you require custom body shapes, specialized pickup configurations, branded finishes, or genre-specific features (e.g., high-output pickups for metal or hollow-body designs for jazz), we empower you to commission instruments precisely engineered to your specifications. Our team works closely with manufacturers to translate your ideas into tangible products, ensuring the final electric guitars perfectly align with your target audience and operational goals.

Gründliche Überprüfung der Lieferanten

Our commitment to quality begins with rigorous due diligence. Before partnering with any electric guitar manufacturer, we conduct comprehensive factory verifications that cover three core areas: (1) confirming production capacity (e.g., monthly output, ability to handle bulk orders); (2) assessing quality control protocols (e.g., inspection processes for wood selection, electronic component testing, and playability checks); and (3) verifying compliance with industry standards (e.g., China’s CCC certification, EU RoHS, and US FCC requirements). This meticulous audit process eliminates risks of partnering with unqualified suppliers.

Experte für Preisverhandlungen

Leveraging our veteran status in the Chinese electric guitar market and long-standing relationships with top manufacturers, IMEXsourcing excels in negotiation. We have a clear understanding of production costs, market pricing trends, and supplier capabilities—allowing us to secure the most favorable pricing and terms for you. Whether you’re purchasing entry-level models or high-end custom guitars, we ensure you get cost-efficient solutions without compromising on quality, craftsmanship, or after-sales service, ultimately optimizing your investment return.

Strenge Qualitätssicherungsmaßnahmen

IMEXsourcing implements a robust quality management framework that spans the entire electric guitar procurement cycle. This includes: (1) pre-production supplier selection (based on our verification process); (2) in-production oversight (on-site inspections to check wood processing, hardware installation, and electronic assembly); and (3) pre-shipment testing (comprehensive checks of playability, tone, hardware functionality, and compliance with your specifications). Every electric guitar undergoes rigorous testing before shipment, guaranteeing its integrity, performance, and adherence to your requirements.

IX. Schlussfolgerung

In conclusion, the Chinese electric guitar market presents abundant opportunities for global buyers. By carefully researching product categories (from entry-level models for beginners to professional-grade instruments for musicians), clarifying technical specifications (such as wood materials, pickup types, and hardware configurations), and following a systematic procurement process, importers can source high-quality, cost-effective electric guitars to meet diverse market demands—whether for retail, music education, or custom brand needs.

Notably, Tangwu Town (in Changle County, Shandong Province), China’s largest electric guitar production base, is home to 108 professional electric guitar manufacturers. While many of these enterprises excel in production craftsmanship and quality control, a significant number lack independent foreign trade capabilities—such as expertise in international logistics, language support for overseas clients, and compliance with global certification standards (e.g., EU CE, US FCC). This is where partnering with IMEXsourcing becomes your optimal choice: we bridge the gap between these capable manufacturers and global buyers, leveraging our local resources and trade expertise to streamline procurement, ensuring you access top-tier products without the barriers of limited foreign trade capacity.

Moreover, collaborating with reliable partners like IMEXsourcing and conducting thorough due diligence (including factory verification, pre-shipment quality inspections, and cost transparency checks) not only makes the procurement process efficient but also minimizes risks associated with international trade—such as quality inconsistencies, delivery delays, or certification non-compliance. This strategic approach not only enhances the value of your procurement (securing high-quality guitars at competitive prices) but also fosters long-term, trustworthy business relationships. In turn, this contributes to sustained profitability for your business and strengthens your competitiveness in the global electric guitar market.