Introduction

Boost Your Project Efficiency with Elite Chinese Construction Material Suppliers by IMEXsourcing

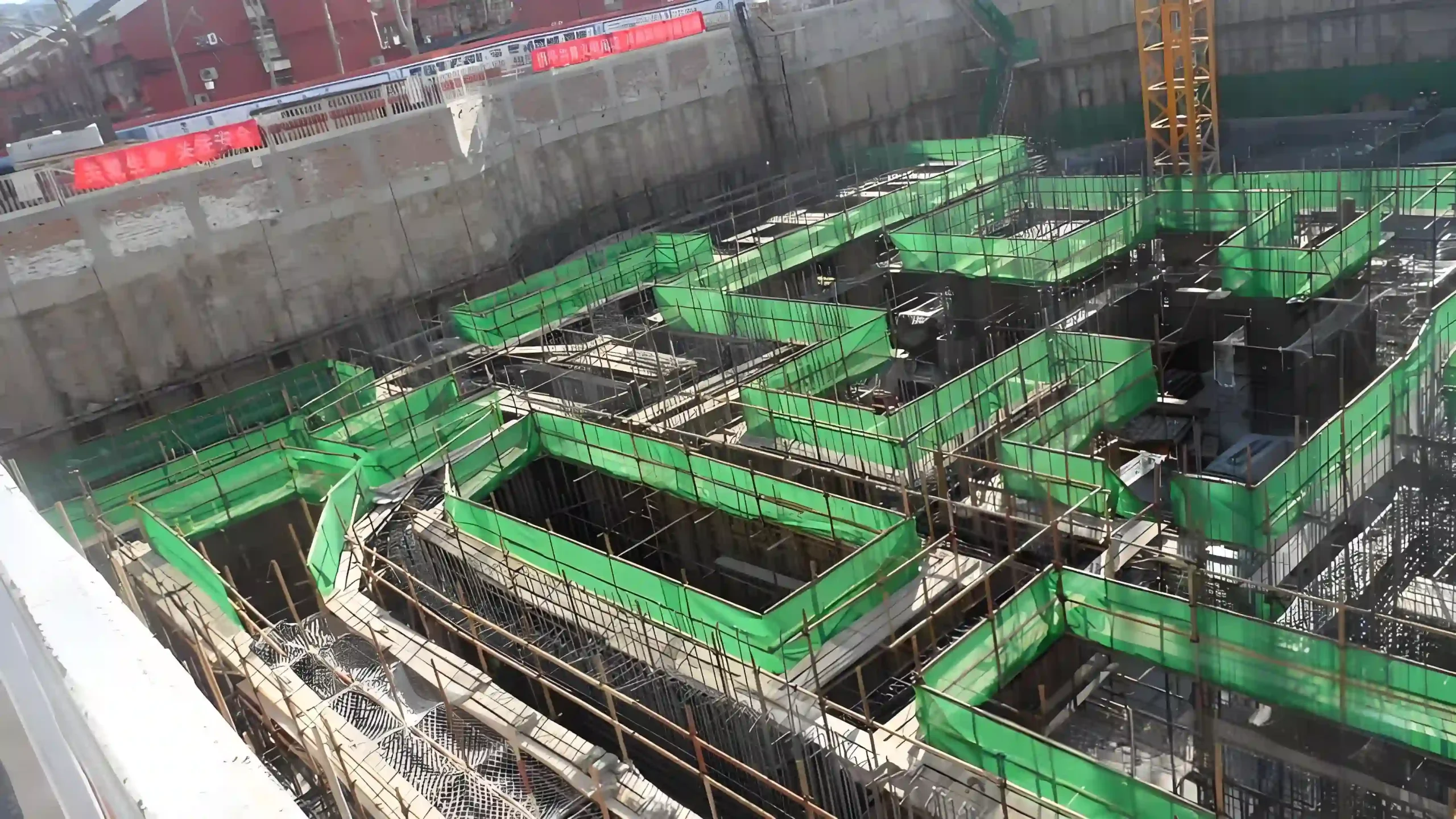

The success of any global construction project hinges on two critical factors: the quality of the raw materials and the efficiency of the supply chain. China, the undisputed global manufacturing powerhouse, offers an unparalleled variety of construction and building materials, from essential structural components to sophisticated power tools. However, navigating this vast landscape—with its thousands of suppliers, complex logistics, and stringent quality control requirements—is a daunting task for international buyers.

This is where the expertise of a dedicated China Sourcing Agent becomes invaluable. By leveraging a centralized, trade-and-logistics-integrated procurement strategy, international construction firms can drastically reduce costs, mitigate risks, and ensure on-time delivery of a diverse range of materials.

This comprehensive guide is designed to walk you through the entire procurement process, focusing on key construction materials used on building sites—including formwork, timber, scaffolding, fasteners, tools, and large machinery—and demonstrating the transformative advantages of utilizing a professional Sourcing Agent.

Table of Contents

I. Overview of Major Chinese Construction Materials (Product Type Introduction)

A typical construction site requires a vast array of products, which can be broadly categorized into four main groups. Understanding the role and composition of each is the first step in strategic sourcing.

1. Structural and Temporary Support Systems

These materials form the backbone of the construction process, providing temporary molds and permanent shelters.

-

Construction Formwork (Building Templates): Primarily plywood, plastic, or steel panels used as a temporary mold to hold concrete while it sets. Plywood is the most common, categorized by the core material (poplar, birch, eucalyptus) and the surface film (phenolic resin film). Steel and plastic formwork are increasingly used for their high reuse rate and smooth finish.

-

Square Timber/Lumber: Used for supports, bracing, and secondary structural components in formwork and temporary structures. Typically sourced from fast-growing, dense woods like fir or pine, often treated for moisture and pest resistance.

-

Scaffolding: Temporary external or internal support structures allowing workers to access high areas. The dominant systems in China are Ringlock, Cuplock, and Kwikstage, chosen for their safety, stability, and ease of assembly. Materials are typically high-strength steel tubes.

-

Container Houses & Prefabricated Houses: Essential for temporary site offices, worker accommodation, and storage. Container houses (ISO-standard or modified) offer quick deployment and mobility. Prefabricated houses utilize light-gauge steel framing (LGSF) and sandwich panels for rapid, modular construction.

2. Fasteners, Consumables, and Hardware

These are the essential linking and supporting components that ensure structural integrity and operational flow.

-

Iron Nails & Binding Wire: Iron nails (common wire nails, concrete nails) are fundamental for timber framing and temporary structures. Binding wire (usually black annealed or galvanized) is crucial for securing reinforcing steel bars (rebar) before concrete pouring, ensuring the rebar cage remains intact.

-

General Hardware and Fittings: A broad category including bolts, nuts, washers, brackets, connectors, and various metal fittings required for assembling scaffolding, formwork, and securing permanent building components. Quality and material grade (e.g., stainless steel, carbon steel with galvanization) are paramount.

-

Safety and Labor Protection (PPE): Encompasses Personal Protective Equipment (PPE) such as safety helmets, gloves, safety harnesses, boots, and high-visibility vests. Security and safety products include perimeter fencing, surveillance systems, fire suppression equipment, and site signage. Compliance with international safety standards is non-negotiable.

3. Tools, Power, and Machinery

The equipment necessary for material processing, assembly, and core construction work.

-

Electric/Power Tools: Handheld or portable electrically powered devices like rotary hammers, angle grinders, circular saws, and demolition breakers. Reliability and ergonomic design are key due to continuous, heavy usage.

-

Manual/Hand Tools: Non-powered tools such as wrenches, spanners, pliers, tape measures, trowels, and shovels. While seemingly simple, their material quality (e.g., chrome-vanadium steel for durability) dictates longevity.

-

Large Construction Equipment: High-value, heavy-duty machinery vital for major operations, including Tower Cranes, Mobile Cranes, Concrete Mixer Trucks, excavators, and bulldozers.

-

Generator Sets: Essential power sources for sites lacking permanent grid access or for emergency backup, ranging from small portable units to large, containerized diesel generators.

II. Key Specifications and Parameters

Procurement success relies on accurately specifying requirements. Using a Sourcing Agent ensures that product specifications meet both the buyer’s needs and international industry standards.

| Product Category | Main Specifications/Parameters | Critical Selection Factors |

| Construction Formwork | Thickness: 9mm, 12mm, 15mm, 18mm. Core Material: Poplar (lighter), Birch/Eucalyptus (denser, stronger). Glue: WBP (Weather and Boil Proof – for exterior/structural use) vs. MR (Moisture Resistant). Film: Density (typically 120g/m² to 240g/m² phenolic film). |

Number of reuse cycles, water resistance of the edge sealant, flatness, and weight per sheet. |

| Scaffolding | System Type: Ringlock, Cuplock, Kwikstage. Steel Grade: Q235, Q345 (Higher grade for higher load capacity). Tube Diameter: Typically 48.3mm (OD). Wall Thickness: 3.2mm or 4.0mm. Load Capacity: Must meet local and international safety load standards (e.g., EN 12811). |

Welding quality (crucial for safety), hot-dip galvanization thickness (for corrosion resistance), fit and alignment of components. |

| Binding Wire/Nails | Binding Wire: Gauge/Diameter (e.g., 18# / 1.2mm), Material: Black Annealed (soft, most common), Galvanized (rust-resistant). Nails: Length (e.g., 1 inch to 4 inches), Gauge, Tensile Strength. |

Purity and softness (for easy tying) of binding wire, consistent diameter, corrosion protection for nails (e.g., hot-dip galvanized). |

| Power Tools | Voltage: 18V/20V (Cordless) or 220V/110V (Corded). Power/Wattage: (e.g., 850W Angle Grinder). Speed: RPM (Revolutions Per Minute). Impact Energy: Joules (for Rotary Hammers). Safety Features: Torque control, anti-vibration systems, double insulation. |

Motor type (Brushed vs. Brushless), battery capacity (Ah) and charging time, compliance with CE/UL/ETL standards. |

| Concrete Mixer Trucks | Capacity: 6 CBM, 8 CBM, 10 CBM, 12 CBM (Cubic Meters). Chassis: Specific Chinese (e.g., SINOTRUK, FOTON) or international brands. Engine: Power (HP), Fuel efficiency, Emission standards (e.g., Euro V, VI). Drum Rotation Speed. |

Drum material thickness (wear resistance), hydraulic system reliability, weight distribution, and maneuverability. |

| Generator Sets | Prime/Standby Power: kVA or kW rating. Engine Brand: (e.g., Perkins, Cummins, Yuchai). Alternator Brand: (e.g., Stamford, Leroy Somer). Fuel Type: Diesel (most common), Natural Gas. Voltage and Frequency: 400V/50Hz or 480V/60Hz. |

Fuel consumption rate, noise level (dB), ease of maintenance, and availability of local after-sales support for the engine/alternator brand. |

| PPE/Safety | Helmets: Standard (e.g., EN 397). Gloves: Material (Nitrile, Leather), Cut Resistance Level (e.g., EN 388). Safety Shoes: Steel toe cap rating (e.g., EN ISO 20345), anti-slip rating. |

Crucially, all PPE must hold valid international certifications (CE, ANSI, ISO) to ensure worker protection and meet liability requirements. |

III. China’s Industrial Clusters

The concentration of specific manufacturing capabilities in geographical clusters is a key advantage of sourcing from China. These clusters offer lower logistics costs, specialized labor, and intense competition, which benefits the buyer.

| Product Category | Key Industrial Cluster(s) | Cluster Focus & Advantage |

| Formwork & Plywood | Linyi (Shandong Province), Pizhou (Jiangsu Province) | Linyi is the largest wood-based panel production base globally, specializing in construction-grade plywood, film-faced plywood, and bamboo formwork. Offers low cost and massive production capacity. |

| Scaffolding & Structural Steel | Tianjin (Daqiuzhuang Area), Cangzhou (Hebei Province) | Daqiuzhuang is a global hub for steel pipe and fittings, ensuring high-volume, standardized production of scaffolding components and steel props. Proximity to Tianjin port facilitates export. |

| Small Tools & Hardware (Fasteners, Hand Tools) | Yongkang (Zhejiang Province), Danyang (Jiangsu Province) | Yongkang is famous as the “Hardware Capital of China”, specializing in power tools, measuring tools, and general-purpose hardware. Focus on rapid iteration and cost-effective production. |

| Large Construction Equipment & Machinery | Xuzhou (Jiangsu Province), Changsha (Hunan Province), Shandong Province (Various Cities) | Xuzhou (XCMG), Changsha (Sany, Zoomlion) are home to China’s largest heavy machinery manufacturers, specializing in cranes, concrete pump trucks, and excavators. Known for robust, scaled production. |

| Container & Prefab Houses | Guangzhou/Foshan (Guangdong Province) Weifang (Shandong Province) |

These coastal areas specialize in modular building systems, benefiting from access to high-quality steel (from nearby steel mills) and proximity to major shipping ports for global delivery. |

A Sourcing Agent is essential for effectively managing procurement across these diverse clusters, consolidating orders and quality checks before final shipment.

IV. Relevant Certification Requirements

For construction materials, quality and safety certifications are not just desirable—they are mandatory for market entry and liability protection.

1. Quality Management and General Product Standards

-

ISO 9001: Nearly all reputable Chinese suppliers hold this certification, signifying adherence to international quality management systems.

-

CE Marking (Conformité Européenne): Mandatory for all relevant products (especially power tools, machinery, and some PPE) entering the European Economic Area (EEA), indicating conformity with health, safety, and environmental protection standards.

-

TÜV/SGS: Independent third-party inspection and testing certifications are often requested by international buyers to confirm product quality (material, load capacity, welding) before shipment.

2. Structural and Safety Certifications

-

Scaffolding: Must comply with standards like EN 12810/12811 (European), BS 1139 (British), or AS/NZS (Australian/New Zealand). A reputable manufacturer will have test reports from accredited labs confirming the scaffolding’s load-bearing capacity.

-

PPE: Must meet the standards of the intended market: ANSI/ISEA (American National Standards Institute), OSHA (Occupational Safety and Health Administration), or EN Standards (e.g., EN 397 for safety helmets, EN 388 for protective gloves).

-

Formwork: While primary standards relate to glue and material (e.g., WBP glue for exterior use), performance often relies on testing for moisture resistance, bending strength, and modulus of elasticity, often confirmed by lab test reports.

3. Electrical and Mechanical Equipment

-

Power Tools and Generator Sets: Must have certifications such as UL (Underwriters Laboratories) or ETL (Intertek) for the North American market, ensuring electrical safety.

-

Large Machinery: Requires conformity certificates relating to emission standards (for engine-driven machines), road safety certifications (for concrete trucks), and operational safety standards.

The Sourcing Agent’s Role: A professional Sourcing Agent vets suppliers to ensure they possess current and valid certifications, and critically, arranges independent third-party inspections to verify that the actual batch of products being shipped meets the certified standards, closing the gap between a certificate and the final product quality.

V. Selection and Procurement Considerations

Beyond specifications and certifications, successful procurement requires diligence in vetting suppliers and managing the purchase process.

1. Supplier Vetting: Capability and Reliability

-

Factory Audit vs. Trading Company: A Sourcing Agent can conduct a comprehensive factory audit to verify the supplier’s genuine manufacturing capability, ensuring they are not just a middleman.

-

Production Capacity: Ensure the factory can handle the required Minimum Order Quantity (MOQ) and meet the production timeline. This is crucial for large-volume items like scaffolding and fasteners.

-

Export Experience: Verify the supplier has experience exporting to your specific country, understanding the required customs documentation, packaging rules, and quality standards of that region.

2. Product Quality Control (QC)

-

Pre-Production Sample: Always demand a sample that accurately reflects the final product before mass production begins (e.g., a scaffold ledger, a set of power tools, or a sheet of formwork).

-

In-Line and Pre-Shipment Inspection (PSI): The Sourcing Agent’s team should perform QC during production (to catch welding defects, material substitution, or incorrect dimensions) and a final PSI (AQL inspection) to verify quantities, packaging, and quality before the final payment and shipment.

-

Material Testing: For high-risk products like scaffolding or high-strength bolts, request a Material Test Report (MTR) from an independent lab to confirm the chemical composition and mechanical properties of the steel.

3. Logistics and Packaging Requirements

-

Container Optimization: Construction materials like scaffolding tubes and lumber are bulky. Efficient loading and container utilization (e.g., fitting 40ft HQ containers with optimal stacking) are essential for reducing freight costs.

-

Durable Packaging: Ensure formwork edges are properly protected, small hardware is packaged in durable cartons to prevent spillage, and heavy machinery is secured against shifting during ocean transit.

4. Financial and Legal Management

-

Incoterms: Clearly define the terms of trade (e.g., FOB, EXW, CIF) and responsibilities for shipping and insurance.

-

Payment Terms: Standard T/T (Telegraphic Transfer) deposits (30% upfront, 70% upon completion of QC/before shipment) are common, but L/C (Letter of Credit) may be used for high-value machinery.

VI. The Integrated Advantage: Trade and Logistics

The single greatest advantage a Sourcing Agent provides is the seamless integration of trade services and logistics management, often referred to as “Integrated Trade and Logistics” or “Trade and Logistics Integrated”. This system is perfectly suited for the diverse, multi-cluster sourcing required for construction projects.

1. Centralized Consolidation and Multi-Vendor Management

-

The Problem: A buyer typically sources formwork from Shandong, scaffolding from Tianjin, power tools from Zhejiang, and PPE from Guangzhou—four different suppliers, four separate logistics challenges.

-

The Sourcing Agent Solution: The agent serves as a single point of contact, managing the production, QC, and collection of goods from all four suppliers. They consolidate all materials into one, or a few, full containers (FCL) at their central warehouse or a strategically located port. This eliminates expensive Less than Container Load (LCL) fees and ensures the goods arrive at the destination port simultaneously.

2. Cost and Time Efficiency in Logistics

-

Optimized Freight Rates: Professional sourcing agents have established relationships with multiple freight forwarders, allowing them to negotiate significantly better sea freight rates and ensure container availability, which is critical in volatile shipping markets.

-

Reduced Documentation Errors: Managing a single set of documents (Bill of Lading, Commercial Invoice, Packing List, Certificate of Origin) for consolidated goods, rather than four separate sets, drastically reduces the risk of customs delays and associated demurrage charges at the destination.

-

Tariff and Compliance Expertise: They ensure all HS codes and product descriptions align with export/import regulations, proactively addressing potential tariff disputes or compliance issues before the ship even sails.

3. Comprehensive Risk Mitigation

-

Single-Point Quality Check: All materials, regardless of origin cluster, pass through the agent’s final QC process at the consolidation point. If a piece of hardware from Zhejiang is missing or defective, it is caught before it enters the container with the scaffolding from Tianjin, allowing for immediate rectification.

-

Supplier Accountability: The agent bears the responsibility for ensuring all materials meet the agreed-upon delivery timeline, managing the individual factory production schedules to prevent any single delay from crippling the entire shipment.

4. End-to-End Service Model

The integrated model extends beyond the port, often offering DDP (Delivered Duty Paid) service, which covers sea freight, insurance, destination customs clearance, and local delivery to the final job site. This hands-off approach allows the construction firm to focus entirely on its core competency: building.

VII. Why Choose IMEX Sourcing as the Agent for Construction Materials?

Sourcing construction materials is fundamentally different from sourcing consumer goods. The products are large, diverse, geographically scattered, and carry high safety risks. Choosing a specialized Sourcing Agent like IMEXsourcing transforms this complex process into a seamless, risk-free operation.

-

Consulting Services Tailored to Your Needs: We understand that every project has unique requirements, from tropical-grade timber treatments to seismic-resistant scaffolding standards. Our experts provide personalized consulting to match your project specifications with the correct Chinese standards and suppliers.

-

Rich Experience in Multi-Cluster Sourcing: Our deep knowledge of China’s industrial geography allows us to efficiently combine purchases from Linyi (formwork), Tianjin (scaffolding), and Yongkang (tools), maximizing container space and reducing total landed cost.

-

Efficient and Dedicated Team: From material composition testing (e.g., steel MTRs) to load-bearing checks on safety harnesses, our dedicated QC team works tirelessly to ensure every single product meets stringent international safety and quality protocols.

-

Comprehensive Market and Product Research: We track the ever-changing material costs (e.g., steel and lumber), supplier reputation, and emerging technologies (like new modular housing solutions), providing you with a competitive edge and ensuring you are always sourcing the best value products.

By choosing an agent that offers true Integrated Trade and Logistics, you are not just outsourcing purchasing; you are investing in a strategic partnership that ensures your entire construction material supply chain is safe, cost-effective, and absolutely reliable.

Ready to streamline your construction supply chain? Contact us today for a free consultation and let us help you build your next success story.