Introduction

The global construction industry is undergoing a paradigm shift. With rapid urbanization across Africa, Southeast Asia, and South America, the demand for sustainable, cost-effective building materials has never been higher. At the heart of this revolution lies the Brick Making Machine—a critical piece of industrial equipment that transforms raw materials like sand, cement, fly ash, and construction waste into the literal foundations of our cities.

China has emerged as the undisputed global hub for brick-making technology. From simple, hand-operated presses for rural development to massive, fully automated hydraulic production lines capable of outputting tens of thousands of blocks daily, Chinese manufacturers offer a range of solutions that balance performance with price. However, for international buyers, the sheer scale of the Chinese market can be overwhelming. You are not just buying a machine; you are investing in a production system that involves hydraulic pressures, vibration frequencies, mold precision, and long-term after-sales support.

This comprehensive guide, modeled on professional sourcing practices, provides everything you need to know to successfully source brick-making machines from China. Whether you are a construction firm looking to reduce material costs or an entrepreneur starting a block factory, this guide will navigate you through the technical, geographical, and strategic landscape of the industry.

Table of Contents

I. Understanding the Diverse Types of Chinese Brick Making Machines

The Chinese market classifies brick-making machines primarily by their level of automation and their driving mechanism. Choosing the right type depends on your budget, target output, and local labor costs.

A. Manual Brick Making Machines

These are the entry-level solutions, often used for small-scale projects or in areas with limited electricity.

-

Mechanism: Hand-operated levers or simple foot pedals provide the compression.

-

Pros: Extremely low cost ($500–$2,000), portable, and requires no complex maintenance.

-

Cons: Low density/strength of bricks, inconsistent quality, and low output (typically 500–1,000 bricks per day).

B. Semi-Automatic Brick Making Machines

A popular choice for small-to-medium enterprises (SMEs). They combine manual material feeding with mechanical/vibratory pressing.

-

Mechanism: Uses electric motors for vibration and hydraulic or mechanical pressing, but requires workers to load raw materials and move the finished pallets.

-

Pros: Good balance between cost and speed; produces bricks with much higher density than manual machines.

-

Cons: Still labor-intensive (requiring 4–6 workers).

C. Fully Automatic Hydraulic Machines

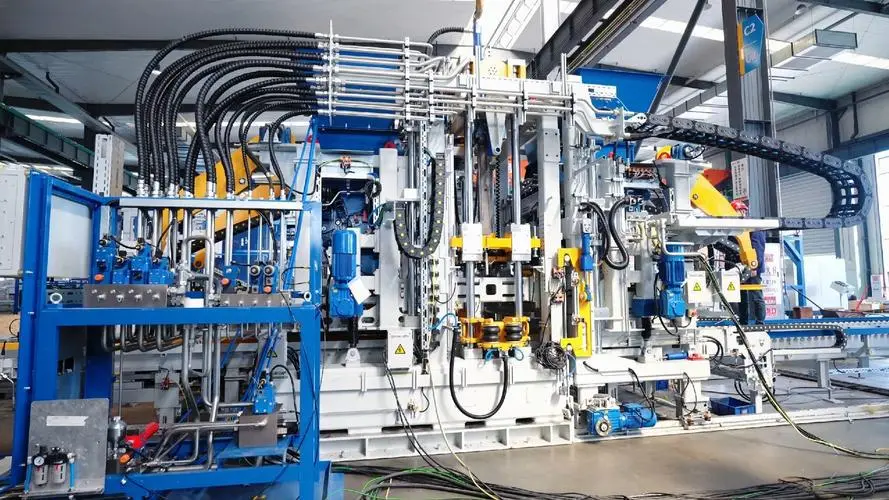

These are high-tech production lines designed for 24/7 industrial operation.

-

Mechanism: Controlled by a PLC (Programmable Logic Controller), these machines automate everything from batching and mixing to molding and stacking. They use advanced hydraulic pressure (often exceeding 12-20 MPa) combined with high-frequency vibration.

-

Pros: Massive output (up to 20,000+ blocks per 8-hour shift), superior block strength, and minimal labor (1–2 operators).

-

Cons: Significant capital investment ($30,000–$150,000+) and requires a stable power grid.

D. Mobile (Egg-Laying) Machines

A unique category where the machine “walks” on a concrete floor, laying bricks as it moves, eliminating the need for pallets.

-

Best For: Rural road construction or projects where pallet costs and transport are a bottleneck.

II. The Production Ecosystem: Auxiliary Equipment

A brick machine is rarely a standalone purchase. To achieve high efficiency and consistent quality, you must consider the “Auxiliary Equipment” that completes the production line.

-

Concrete Mixer (Planetary vs. Twin-Shaft): The heart of material preparation. Twin-shaft mixers are standard for high volume, while planetary mixers are preferred for colored pavers to ensure uniform pigment distribution.

-

Belt Conveyor: Transports the mixed wet concrete from the mixer to the machine’s hopper.

-

Automatic Batching Machine: Uses load cells to precisely weigh cement, sand, and aggregates according to a pre-set recipe.

-

Automatic Stacker (Cuber): Picks up the loaded pallets of wet bricks and stacks them for transport to the curing area.

-

Pallet Feeder: Automatically feeds empty pallets into the machine.

-

Molds: The most critical consumable. High-quality Chinese molds are heat-treated (carburized) to ensure they can withstand 100,000+ cycles before wearing out.

III. Why Concrete? The Advantages of Non-Burning Brick Technology

Chinese machinery has spearheaded the move away from traditional clay-fired bricks toward Non-Burning (Concrete/Cement) Blocks. The advantages are compelling:

-

Environmental Sustainability: Unlike clay bricks, these do not require fertile topsoil or high-temperature kilns that emit massive CO2. They utilize fly ash, slag, and construction waste.

-

Cost-Efficiency: The raw materials (sand, stone dust, gravel) are often cheaper and more widely available than high-quality clay.

-

Structural Superiority: Concrete blocks are more uniform in size, which reduces the amount of mortar required during construction by up to 30%.

-

Insulation: Hollow concrete blocks provide better thermal and sound insulation compared to solid red bricks.

IV. Key Technical Specifications and Parameters for Buyers

When comparing quotes from different Chinese suppliers, do not just look at the price. Look at these “Core Specs”:

| Parameter | Significance | Standard Benchmarks |

| Cycle Time | How long it takes to make one “press.” | 15–25 seconds for auto machines. |

| Vibration Frequency | Higher frequency = denser, stronger bricks. | 3,000–4,500 rpm (Servo motors are best). |

| Hydraulic Pressure | Determines the compaction force. | 12 MPa to 21 MPa for heavy-duty lines. |

| Pallet Size | Limits how many bricks you can make per cycle. | e.g., 850x550mm or 1100x700mm. |

| Total Power | Crucial for calculating operational costs. | 15kW for small; 50kW+ for large lines. |

| Control System | The “brain” of the machine. | Look for Siemens PLC or Schneider components. |

V. Product Versatility: Types, Styles, and Sizes of Bricks Produced

By simply changing the mold, a single Chinese brick machine can produce dozens of different products:

-

Hollow Blocks: The standard for wall construction. Sizes like 400x200x200mm (8-inch) or 400x150x200mm.

-

Solid Bricks: For load-bearing structures. Common size: 240x115x53mm.

-

Interlocking Pavers: Used for driveways and parking lots. Includes “I-shape,” “Hexagon,” and “Zig-zag” patterns.

-

Color Pavers: Machines with a “Face-mix” device can add a thin layer of colored concrete to the top of a block, saving on pigment costs.

-

Curbstones & Grass Bricks: For landscaping and municipal road projects.

-

Hourdis Blocks: Specialized hollow blocks used for floor slabs.

VI. China’s Brick Machinery Industrial Clusters

Geography plays a huge role in sourcing. Most manufacturers are concentrated in three provinces:

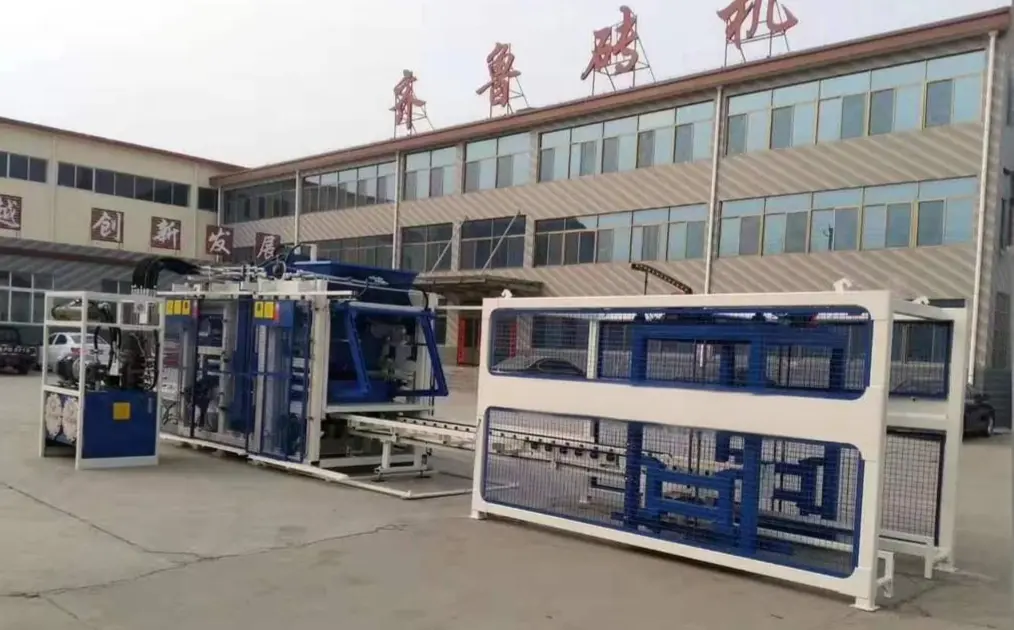

- Linyi, Shandong Province (The Volume Hub):Linyi is the “Capital of Brick Machines.” It hosts hundreds of factories ranging from small family workshops to massive industrial groups. If you are looking for cost-effective, mid-range machines (like the QT4-15 or QT4-24 models), Linyi is the place.

- Quanzhou, Fujian Province (The High-End Hub):Fujian manufacturers focus on high-tech, export-quality machinery. Many companies here have collaborated with German firms (e.g., QGM’s acquisition of Zenith). If you need a premium, fully automatic line for a large-scale plant, look here.

- Gongyi/Zhengzhou, Henan Province (The Clay Specialist):While the world is moving to concrete, if you specifically need Vacuum Extruders for clay/fired bricks, Henan is the historical center for this technology.

VII. Top Chinese Brick Making Machine Manufacturers

Note: Always conduct fresh due diligence before ordering.

- QGM (Quangong Machinery Co., Ltd.) – Fujian https://www.qgmblockmachine.com

The industry leader. They acquired the German brand Zenith and offer the “ZN” series which represents the pinnacle of Chinese/German engineering. Best for high-budget, high-output projects.

- Hongfa Group – Shandong https://www.hongfamach.com

One of the oldest and largest manufacturers. They specialize in integrated production lines, including AAC (Autoclaved Aerated Concrete) lines and large-scale block machines.

- REIT – Fujian https://www.reitmachine.com

Known for high-end automatic systems with a strong focus on “Smart” manufacturing and remote diagnostics.

- Qunfeng Machinery – Fujian https://www.qunfeng.com

A very popular export brand. Their machines are known for aesthetic design and user-friendly PLC interfaces.

- Dongyue Group – Shandong https://www.donyuegroup.com

A massive conglomerate that produces everything from simple manual machines to massive chemical-processing equipment. Very reliable for mid-to-high-tier buyers.

- Fulang Machinery – Shandong https://www.blocksmachine.com

A leader in the Linyi cluster. Excellent for entrepreneurs and SMEs looking for reliable, cost-effective hydraulic machines with great after-sales support.

- Shengya Machinery – Shandong https://www.sdshengya.com

Similar to Fulang, they have a massive presence across Africa and Southeast Asia with local service centers in many countries.

- Aimix Group – Henan https://www.aimixgroup.com

A diversified construction machinery supplier. They are great for buyers who need to bundle brick machines with other equipment like concrete pumps or batching plants.

- ZCJK Group – Wuhan Hubei http://www.wh8108.cn/

Literally China Materials Construction Tech Group, specializing in the research of new wall materials, comprehensive utilization of solid waste resources, complete sets of brick-making machine machinery and equipment.

- Allian Machinery – Shandong

VIII. Sourcing Considerations and Buying Checklist

Sourcing heavy machinery is different from sourcing consumer goods. One mistake can lead to months of downtime.

1. The “Real” Capacity vs. “Theoretical” Capacity

Manufacturers often quote capacity based on a 15-second cycle time. In reality, due to material loading and worker speed, your actual output might be 20% lower. Always plan your plant layout based on 80% efficiency.

2. Power Supply Compatibility

China uses 380V/50Hz/3-Phase. If your country uses 220V, 415V, or 60Hz, you must specify this. Changing a motor after the machine arrives is expensive and difficult.

3. Spare Parts Package

A machine is only as good as its uptime. Ensure your quote includes a 2-year wear-and-tear kit:

-

Proximity switches and relays.

-

Hydraulic seals and O-rings.

-

Vibration springs.

-

Additional mold liners.

4. Factory Acceptance Test (FAT)

Before the final payment, the machine must be tested.

-

Ask for a video of your specific machine running with molds.

-

Verify the vibration noise (excessive noise indicates poor balancing).

-

Check the welding quality on the main frame.

5. Logistics: The Container Challenge

Large machines are heavy. A QT10-15 line can require multiple 40ft HQ containers. Ensure the supplier packs the machine with anti-rust oil and secures it properly to prevent shifting during ocean transit.

IX. Why Choose IMEXsourcing as Your Machinery Partner

At IMEXsourcing, we understand that buying a brick machine is a high-stakes investment. We act as your eyes and ears on the ground in China to mitigate risks.

-

Deep Supplier Audits: We don’t just look at Alibaba profiles. We visit the factories in Linyi or Quanzhou to verify their actual manufacturing capacity, the quality of their steel, and the authenticity of their “Siemens” components.

-

Technical Inspection: Our inspectors check the thickness of the steel frames, the quality of the hydraulic pumps, and ensure the PLC is programmed in your local language.

-

Price Negotiation: Because we deal with these clusters daily, we know the “real” factory price. We help you negotiate not just the machine price, but the cost of custom molds and spare parts.

-

Loading Supervision: We ensure that every component—from the tiny sensors to the heavy mixer—is accounted for and safely loaded into the container to prevent transit damage.

-

After-Sales Mediation: If a part fails under warranty, we communicate with the factory in their native language to ensure replacement parts are dispatched immediately, minimizing your downtime.

X. Conclusion

The transition from manual construction to mechanized brick production is one of the most profitable moves a construction business can make. China offers the world’s most versatile range of brick-making machinery, capable of meeting any budget or production scale.

However, success lies in the details. By understanding the difference between a Linyi-made mid-range machine and a Quanzhou-made premium line, specifying the right technical parameters, and performing rigorous quality control, you can build a production facility that lasts for decades.

Ready to start your brick production journey? Contact IMEXsourcing today for a consultation on the best manufacturers and equipment configurations for your specific market needs. Let us help you turn Chinese innovation into your local success.