Table of Contents

I. Introduction: The Unsung Workhorse of Global Logistics

In the vast landscape of global supply chains, few products are as critical yet as overlooked as woven packaging. Polypropylene (PP) woven bags, alongside their large-scale counterparts, Flexible Intermediate Bulk Containers (FIBCs)—also known as jumbo or ton bags—serve as the foundational packaging solution for nearly all dry, granular, and powdered goods moved around the world. From agricultural produce and mineral ores to cement and chemical compounds, these bags provide a versatile, durable, and cost-effective method of containment and transport.

China dominates the global supply of these critical packaging materials. Its matured plastics and textile industry, coupled with immense production capacity and advanced weaving technology, positions it as the premier sourcing hub for buyers worldwide. However, navigating the Chinese market requires an in-depth understanding of product specifications, regional specializations, and essential quality controls.

This comprehensive procurement guide, modeled after expert sourcing methodologies, is designed to equip international buyers with the knowledge necessary to successfully source high-quality PP woven bags and FIBCs from reliable Chinese manufacturers.

II. Product Type Introduction and Classification

The term “woven bag” encompasses a broad range of products, each engineered for specific containment and logistics challenges. Understanding the core distinctions is the first step in successful sourcing.

A. Standard PP Woven Bags (Polypropylene Sacks)

These are the most common form of woven packaging, typically designed to hold weights ranging from 5 kg to 100 kg.

-

Definition: Made from weaving flat strands (tapes) of polypropylene into a fabric, which is then cut, printed, and sewn into a sack shape.

-

Typical Applications: Packaging rice, flour, feed, fertilizers, salt, sand, and other granular goods.

-

Key Features: Lightweight, high tensile strength, excellent resistance to tearing and punctures. They can be single-stitched or double-stitched and often feature an open mouth or a heat-cut edge.

B. Specialty & Laminated Woven Bags (High-Performance Sacks)

To address specific requirements such as moisture barrier, enhanced aesthetics, or fine powder containment, standard bags are modified.

-

BOPP Laminated Woven Bags (Bi-axially Oriented Polypropylene):

-

Function: A BOPP film, printed with high-resolution, photographic-quality graphics, is laminated onto the woven fabric.

-

Advantage: Offers superior visual appeal, moisture protection, and scuff resistance, making it ideal for retail-shelf products like premium pet food, specialized fertilizers, or branded rice.

-

-

Lined or Coated Woven Bags:

-

Function: The woven fabric is coated with a thin layer of PP or PE resin (lamination) to seal the porous weave, providing a moisture barrier. Alternatively, an inner liner (usually a loose PE film bag) is inserted for maximum protection against humidity and fine powder leakage.

-

-

Block Bottom/Valve Bags:

-

Function: Bags constructed with a rectangular block bottom (similar to paper sacks) and a self-sealing valve at the top.

-

Advantage: Maximizes pallet utilization, provides a stable, brick-like stack, and prevents product leakage, commonly used for packaging cement, drywall plaster, or chemical powders.

-

C. Flexible Intermediate Bulk Containers (FIBCs) / Ton Bags / Jumbo Bags

FIBCs are designed for bulk handling, typically accommodating 500 kg to 2,000 kg of material. They are critical for efficient storage and shipping via rail, truck, or container ship.

-

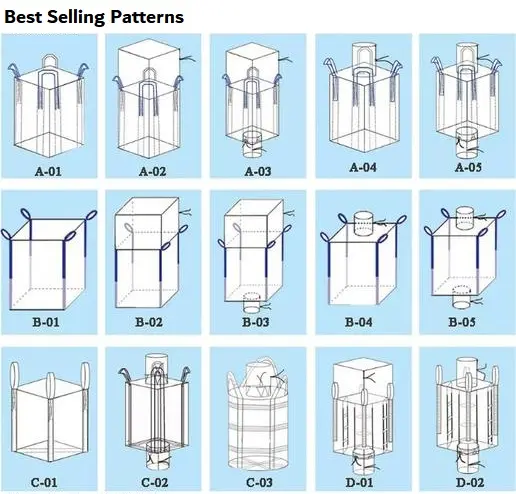

FIBC Construction Types:

-

U-Panel/4-Panel: Constructed from separate pieces of fabric sewn together, offering the best shape-holding capability and stability.

-

Circular/Tubular: Made from a single piece of woven fabric that forms the body, eliminating vertical seams and reducing the chance of failure (cost-effective).

-

Baffle Bags: Incorporate internal fabric panels (baffles) to maintain a square shape when filled. This maximizes container space (up to 30% more product) and prevents the “bellying” effect common in standard FIBCs.

-

-

FIBC Safety and Electrical Types:

-

Type A: Standard FIBCs, no anti-static features. Safe for non-flammable products.

-

Type B: Designed to prevent propagating brush discharges by having a low breakdown voltage. Safe for dry, flammable powders, provided no flammable solvents or gases are present around the bag.

-

Type C (Conductive/Groundable): Constructed with interwoven conductive threads (often carbon fibers) that must be electrically grounded during filling/discharging to safely dissipate static charge. Essential for packaging highly flammable powders or use in highly flammable environments.

-

Type D (Dissipative/Anti-static): Made from static-dissipative fabric that does not require grounding. Utilizes specialty anti-static coatings to safely dissipate static charges into the atmosphere.

-

III. Product Multi-functional Advantages

The Chinese packaging industry has leveraged continuous innovation and economy of scale to endow their woven products with key functional advantages essential for modern logistics.

1. Unmatched Durability and Mechanical Strength

PP woven materials, especially high-denier tapes woven at high density, offer an exceptional strength-to-weight ratio. They are inherently resistant to most mild chemicals, corrosion, and biological damage. This resistance is crucial for agricultural and chemical goods that may undergo prolonged storage. The high tensile strength means these bags can survive the rigors of multi-modal transportation, including repeated lifting by forklifts and container stuffing.

2. Versatile Moisture and Environmental Protection

For products sensitive to moisture (e.g., cement, milk powder, chemicals), Chinese manufacturers offer highly effective barriers:

-

Lamination/Coating: A thin polymer coating prevents moisture from seeping through the weave. This lamination adds a few cents to the cost but exponentially increases the bag’s protective capability.

-

UV Stabilization: For products stored outdoors (such as minerals or construction materials), manufacturers incorporate UV-resistant additives into the PP resin during the tape extrusion process. This stabilization extends the bag’s service life significantly, often rated for 1,600 to 3,000 hours of sunlight exposure, preventing premature degradation and catastrophic failure during transport and storage.

3. High-Fidelity Customization and Branding

The shift towards BOPP lamination has transformed PP woven bags from plain packaging into powerful branding tools. Chinese printing capabilities allow for up to 10-color photorealistic printing, ensuring that the final package commands attention on a retail shelf or maintains corporate branding standards, even in industrial settings. Furthermore, customization extends to every dimension: loop type, spout size, skirt top, and vent panels.

4. Cost-Efficiency and Sustainable Sourcing Options

China’s massive raw material market and highly automated factories drive down unit costs, making PP woven packaging one of the most cost-effective bulk solutions available globally. Furthermore, in response to global sustainability trends, many Chinese manufacturers now offer:

-

Recycled Content Bags: Utilizing high-quality post-consumer or post-industrial recycled PP (often GRS certified). This allows buyers to meet their own sustainability targets while still benefiting from the cost advantage.

-

Single-Material Designs: Creating bags (e.g., liner-less, non-laminated) that are easier for importers to recycle at the end of their lifecycle, simplifying waste management for the end user.

IV. Key Specifications and Critical Parameters

In sourcing woven bags, specifications are not suggestions—they are precise engineering requirements that dictate the bag’s performance and safety. Misunderstanding these parameters is the primary cause of shipment failures.

| Parameter | Description | Criticality |

| Safety Factor (SF) | The ratio of the maximum load the bag can sustain to its nominal Working Load Limit (WLL). | High. Standard is 5:1 (Single Trip use). 6:1 is required for multi-use or UN Certified bags, signifying a higher strength margin. |

| Working Load Limit (WLL) | The maximum safe weight (in kg/lbs/tons) the bag is designed to carry. | High. Must be clearly marked and strictly adhered to. Exceeding the WLL is dangerous and voids warranties. |

| Fabric Weight (GSM) | Grams per Square Meter. Determines the thickness and inherent strength of the woven fabric. | High. Typically ranges from 140 GSM to 240 GSM for FIBCs, and 50 GSM to 120 GSM for sacks. Lower GSM means lower material cost but greater risk of tear. |

| UV Stabilization | Measured in hours (e.g., 1,600 hours or 3,000 hours). The time the bag can resist UV degradation before losing a certain percentage of its strength. | Medium/High. Crucial for agricultural and construction materials stored outdoors for months. |

| Material Composition | Percentage of virgin PP vs. recycled PP. Virgin PP offers guaranteed consistency and strength. Food-grade applications must use 100% virgin resin. | High. Must meet regulatory or food-grade standards (e.g., FDA/EU food contact). |

| Weave Density | Number of tapes (ends and picks) per unit of measurement (e.g., per 10 cm). Directly impacts puncture resistance and overall tensile strength. | High. A tighter weave is essential for fine powders to prevent sifting. |

| Lifting Loop Strength | The construction (Cross-corner, Side-seam) and material of the loops. Loops must withstand 2-3 times the WLL during testing. | High. Loop failure is the most common point of FIBC breakage during handling. |

V. China’s Industrial Cluster Regions

The concentration of manufacturers in specific regions provides buyers with distinct logistical and price advantages based on the product type they require.

1. Shandong Province: The FIBC and Industrial Bulk Powerhouse

Shandong province stands as the undisputed champion of large-scale industrial packaging in China, particularly for FIBCs and heavy-duty PP woven sacks.

-

Key Hubs: Qingzhou, Zibo, Taian, Linyi and parts of Qingdao.

-

Specialization: This region houses factories with vast weaving and laminating capacity, specializing in Type C and D conductive bags, UN-certified hazardous goods bags, and multi-trip FIBCs used for minerals, chemicals, and construction materials.

-

Advantage: These manufacturers typically possess advanced, vertically integrated production lines, rigorous in-house testing labs, and decades of experience in high-volume, export-quality FIBC manufacturing, serving the world’s largest chemical and mining corporations.

2. Zhejiang Province: Consumer-Grade and BOPP Experts

Zhejiang, especially cities like Wenzhou and proximity to Yiwu, is a core cluster for consumer packaging and high-aesthetic sacks.

-

Key Hubs: Wenzhou (known for flexible packaging).

-

Specialization: Wenzhou-based companies excel in BOPP laminated woven bags, small to medium-sized PP sacks, and woven tote/shopping bags. They focus heavily on high-resolution printing and customization, targeting the retail, food, and agricultural sectors requiring eye-catching shelf presence.

-

Advantage: Suppliers here are highly responsive to custom orders, offer competitive pricing for medium volumes, and benefit from excellent port logistics in Ningbo and Shanghai.

3. Hunan Province: The Cement and Fine Powder Specialists

Specific areas in Hunan, such as Yiyang, have developed a niche expertise focusing on block bottom and valve bag technology.

-

Specialization: Manufacturing the specialized, automated valve bags used extensively for cement, mortar, gypsum, and other fine construction powders. These bags require precise valve formation and high-speed filling capabilities.

-

Advantage: Manufacturers are highly experienced in the precise machinery and material specifications needed to ensure the self-sealing valve functions perfectly under high-speed filling conditions.

VI. Main Domestic Manufacturers in China

Leading Chinese manufacturers distinguish themselves through scale, quality control, and international certification. While the market is fragmented, certain large-scale enterprises, particularly in the Shandong FIBC cluster, lead in export volume and technical compliance. Buyers are advised to prioritize working with companies that exhibit the following profiles:

A. Leaders in FIBC/Jumbo Bag Production (Shandong-based Examples)

These companies often maintain large, dedicated factories with specialized testing capabilities necessary for bulk transportation safety.

-

Shandong Dapoly Group Co., Ltd. (DAPOLY): https://www.dapoly.com A large, vertically integrated group founded in 1997. They control the entire process from plastic extrusion to the final product. Dapoly is known for a wide range of products including FIBCs and woven bags, backed by stringent international certifications (often including FDA, HACCP, and ISO standards).

-

Shandong (Jinyangguang) Golden Sunshine New Material Technology Co., Ltd.: http://www.sunpack.com.cn/ Located in Linyi (Shandong), this manufacturer focuses heavily on export-grade PP Jumbo Bags (Big Bags). They are often recognized for their complete product lines, competitive pricing, and strong reputation for short lead times on high-volume FIBC orders.

-

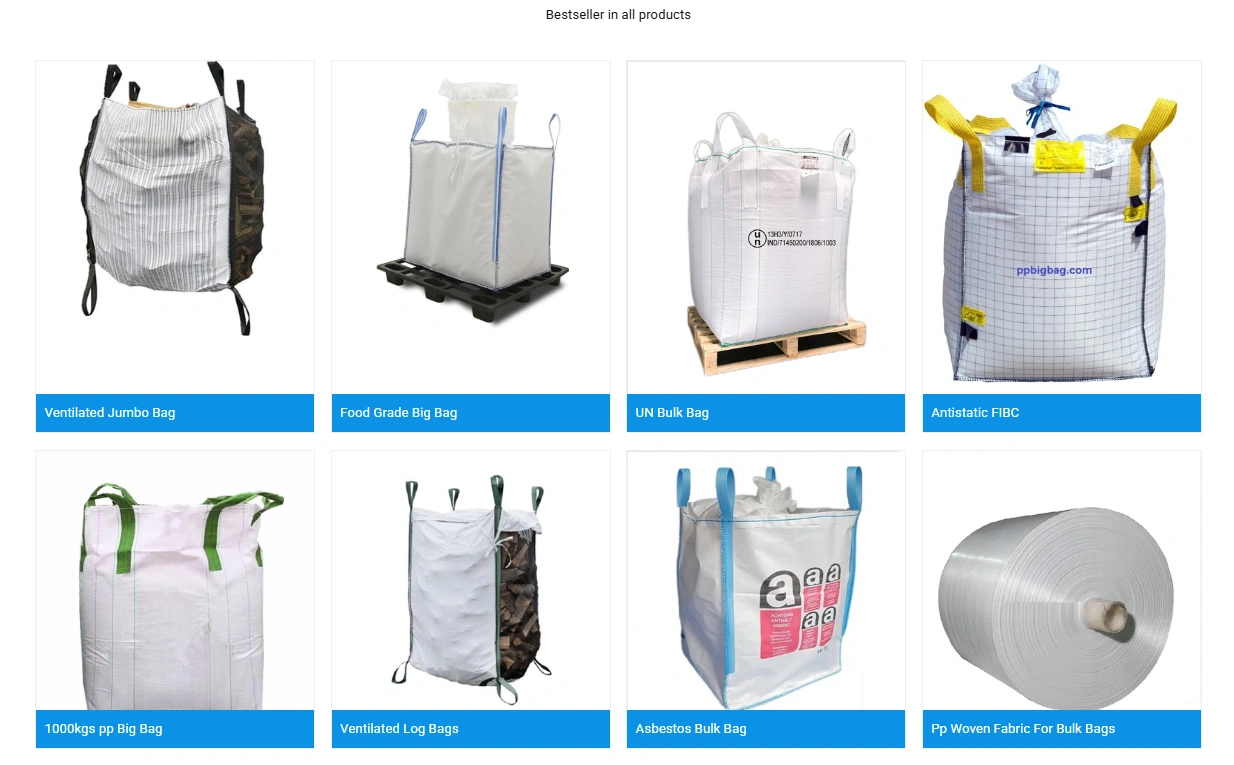

Shandong Guansong Industrial Co.,Ltd.: https://www.ppbigbag.com A major player specializing in high-compliance FIBCs, including sophisticated variants like UN Certified Bags (for hazardous materials), Antistatic Bags (Type C and D), and Food Grade Bags, serving global clients in highly regulated industries.

-

Zibo Yundu Plastic Products Co., Ltd.: https://www.ydbags.com A high-capacity FIBC supplier in the Zibo cluster, known for producing bulk bags tailored for specific materials like stone, seafood, and large sands, indicating diverse load testing capabilities.

B. Leaders in High-End & Specialty Sacks (Others)

These companies focus on material specialization and advanced printing/lamination technologies.

-

Linyi Donglian Import & Export Co., Ltd.: https://www.ppbagwoven.com While located near the Shandong hub, Linyi Donglian is a significant player across jumbo bags, standard PP woven sacks, and mesh bags, demonstrating massive production capacity and a broad product portfolio crucial for diversified buyers.

-

Taihua Plastic Products Co., Ltd (Shanghai/Jiangsu): http://www.taihuapackaging.com/ Although located outside the main Shandong cluster, Taihua is a highly reputable enterprise group known for specializing in high-performance, complex bags such as conductive bags, dangerous goods bags, and clean bags, often servicing pharmaceutical and high-tech chemical clients.

Buyer Strategy: When engaging with these leading firms, leverage their scale to negotiate price, but emphasize the use of their most sophisticated quality control processes and highest certification levels (e.g., asking a Dapoly or Guansong to apply their UN-certified testing protocols to your standard FIBC order).

VII. Essential Certification and Compliance Requirements

Certifications are non-negotiable proof that a Chinese manufacturer can meet global quality, safety, and ethical standards. Failure to confirm relevant certifications can lead to disastrous customs rejections or catastrophic product failures.

1. Foundational Quality and Environmental Standards

-

ISO 9001:2015 (Quality Management): The basic requirement. This confirms the manufacturer has a documented, functioning quality management system from raw material inspection through to final dispatch, ensuring traceability.

-

ISO 14001:2015 (Environmental Management): Essential for demonstrating a commitment to environmental responsibility in the manufacturing process (e.g., waste management, energy consumption).

-

GRS (Global Recycled Standard): Increasingly sought after by North American and European buyers to verify the exact percentage and source of recycled PP content in the bag, providing a reliable chain of custody for sustainability claims.

2. Sector-Specific Safety and Compliance

| Certification/Standard | Required For | Purpose |

| UN Certification | FIBCs used to transport dangerous goods (e.g., certain chemicals, infectious waste). | Confirms the bag passed rigorous drop, stack, and tear tests specific to the product hazard level, enabling legal international shipment of hazardous materials. |

| HACCP / FSSC22000 / BRCGS | Bags intended for direct food contact (e.g., sugar, flour, feed ingredients). | Guarantees the bags are manufactured in a hygienic, controlled (cleanroom) environment, free from contaminants, and compliant with global food safety standards. BRCGS (Global Standard for Packaging Materials) is often the highest packaging safety benchmark. |

| IEC 61340-4-4 | Type C (Conductive) and Type D (Anti-static) FIBCs. | Certifies the bag’s electrical conductivity or static dissipation properties are functional and safe for use in explosive atmospheres (e.g., grain silos, dusty chemical environments). |

| BSCI / Sedex | Manufacturers serving socially conscious brands or retailers (EU/US). | Focuses on labor standards, ensuring ethical working conditions, fair wages, and compliance with local labor laws throughout the supply chain. |

VIII. Critical Purchasing Notes for Importers

The final step is translating the technical requirements into a robust procurement process. Avoiding common pitfalls can save significant time and money.

1. Never Buy on Price Alone: The Hidden Cost of Low GSM

The biggest sourcing mistake is chasing the lowest unit price, which almost always means sacrificing fabric GSM (weight/thickness) and using lower-grade, non-virgin PP resin. The cost of a single shipment failure (product loss, cleanup, legal fees) dwarfs the savings from a thinner bag. Always verify GSM, weave density, and the resin’s Melt Flow Index (MFI) via a third-party inspection before shipment.

2. Demand Detailed Technical Data Sheets (TDS)

Do not rely on pictures or vague descriptions. A professional Chinese manufacturer must provide a TDS for every FIBC or custom sack order, detailing:

-

WLL and SF rating (e.g., 1000kg @ 5:1 SF).

-

The exact resin grade used (e.g., 100% Virgin PP, Raffia Grade).

-

UV stabilization hours (e.g., 1,600 hours).

-

Seam strength guarantees (in N/mm).

-

A certified test report from their in-house or third-party lab matching the bag specification.

3. The Crucial Role of Third-Party Quality Control (QC)

For bulk orders, a pre-shipment inspection (PSI) is mandatory, focusing on:

-

Destructive Testing: Observing the supplier perform certified load and drop tests on a sample batch of FIBCs to ensure they meet the WLL and SF rating.

-

Dimensional Checks: Verifying the bag’s height, width, and loop length conform to the specified dimensions for automated filling lines. Loop height variance can cause serious issues with forklift handling.

-

Visual and Contamination Checks: Ensuring printing registration is accurate, there are no missing stitches, and, critically for food-grade bags, that the inside of the bag is clean, dry, and free from loose threads, lint, or debris.

4. Managing Freight and Logistics

PP woven bags and FIBCs are volumetrically large. Shipping costs are often governed by Cubic Meters (CBM), not just weight.

-

Maximizing Container Space: Discuss packaging and folding techniques with the supplier. Ask them to maximize the bags per pallet and to compress the final palletized goods to minimize air space, ensuring you get the maximum quantity in a 20ft or 40ft HQ container. Leading suppliers have automated compression systems.

-

Documentation: Ensure all required customs documentation—Certificate of Origin, Bill of Lading, and, most importantly, the relevant Certification Certificates (ISO, UN, BRCGS)—are correctly prepared and match the order specification exactly to avoid customs delays.

By following this structured approach—understanding the product’s technical classification, targeting the correct manufacturing cluster, verifying adherence to rigorous international standards, and engaging with documented industry leaders—importers can establish a successful, high-quality, and reliable supply chain for woven packaging from China.

IX. Choosing IMEXsourcing as Your Sourcing Partner for PP Woven Jumbo Bags (FIBCs) in China

When it comes to procuring high-quality PP Woven Jumbo Bags (also known as Flexible Intermediate Bulk Containers or FIBCs) from China, partnering with an experienced and reliable sourcing agent is paramount. IMEXsourcing stands out with a comprehensive service suite designed to streamline your acquisition process and secure exceptional value. Here are compelling reasons to select IMEXsourcing for your next FIBC purchase:

Extensive Procurement Expertise

IMEXsourcing boasts a profound and long-standing history in the sourcing industry, enabling us to proficiently identify and connect with a wide range of reputable Chinese PP woven bag and FIBC suppliers. Our deep market knowledge ensures we match you with manufacturers known for reliability and superior products, covering everything from specialized high-compliance FIBCs (e.g., UN Certified bags for hazardous goods, Type C/D Anti-Static bags, Food Grade BRCGS-certified bags) to mass-produced standard solutions (e.g., 5:1 single-trip U-panel bags, tubular construction sacks, laminated PP woven bags) and custom-labeled sets.

Bespoke Design Solutions

We understand that unique commodity needs often demand tailored solutions. IMEXsourcing empowers you to commission FIBCs aligned with your specific packing requirements—whether it’s specific materials (high-UV stabilized resin, low-MFI virgin PP for strength), construction styles (e.g., baffle bags for max container space, duffle top/discharge spout closures, cross-corner lift loops), or practical details (custom Working Load Limits (WLLs), specific fabric weights in GSM, or precise coating thickness for moisture protection). Each product is precisely engineered to your specifications, ensuring perfect alignment with your logistics and safety requirements.

Thorough Supplier Verification

Our commitment to quality begins with rigorous due diligence. We conduct comprehensive factory audits for all potential manufacturers, verifying their production capabilities (e.g., daily output of FIBCs, inventory of weaving looms, in-house lamination capacity), assessing quality control protocols (e.g., tape tensile strength testing, seam strength analysis, raw material resin MFI checks), and ensuring full compliance with domestic and international industry standards (such as ISO 9001 for quality management, UN Certification requirements, AIB/BRCGS for food-grade compliance) and legal requirements.

Expert Price Negotiation

Leveraging our veteran status and in-depth understanding of market dynamics, IMEXsourcing excels in negotiation. This expertise allows us to secure the most favorable pricing and terms with top-tier FIBC manufacturers renowned for their craftsmanship (e.g., precise loop attachment, reinforced seams), material control (e.g., guaranteed virgin PP use, certified UV additives), after-sales service, and cost efficiency, optimizing your investment.

Stringent Quality Assurance

IMEXsourcing implements a robust quality management framework spanning the entire procurement cycle, including careful supplier selection, diligent production oversight (such as checking final bag dimensions, fabric GSM uniformity, and loop-to-body connection integrity), and thorough pre-shipment testing (such as mandatory Safety Factor (5:1 or 6:1) destructive testing, certification of WLL performance, and packaging compression-resistance tests), guaranteeing the integrity and performance of your PP Woven Jumbo Bags.

X. Conclusion

In conclusion, the Chinese PP Woven Jumbo Bag (FIBC) market presents abundant opportunities for global buyers. By carefully researching product categories (from affordable standard U-panel FIBCs to high-compliance UN Certified bags, specialized Type C/D Anti-Static containers, and complex Baffle Bags), clarifying technical specifications (such as Safety Factor (SF) ratings, fabric GSM and UV stabilization requirements, and specific loop strength certifications), and following a systematic procurement process, importers can source high-quality, cost-effective FIBCs to meet diverse bulk material demands—whether for the agricultural, chemical, construction, or mining sectors.

Partnering with IMEXsourcing provides critical protection for your procurement journey. We understand that the FIBC industry, while stable, requires constant due diligence to mitigate risks associated with sudden factory issues or capacity shortfalls that can lead to order disruptions and advance payment losses. Therefore, we specifically offer factory investigation services: through on-site inspections, we verify the actual operating status of manufacturers (e.g., the operational status of weaving looms and tape extrusion equipment, the stability of the technical employee base), financial health (e.g., checking for potential cash flow problems), and past performance records (e.g., whether there are order delays for critical compliance bags). This helps you screen out high-quality manufacturers with stable operations and strong risk resistance from the source, completely avoiding financial losses and procurement delays caused by unstable supplier performance.