Table of Contents

I. From Manual Stitches to AI Code: China Now Makes Over 80% of the World’s Industrial Sewing Machines

In a smart factory in Taizhou, robotic arms precisely grab soft fabrics and automatically feed them into sewing machines. An AI system monitors the tension of every stitch in real time, while operators control complex processes with simple hand gestures – this is today’s reality in China’s sewing machine industry.

Out of every 10 industrial sewing machines produced globally, over 8 are now made in China. An industry once famous for cheap labor is now redefining the future of sewing production through deep integration of artificial intelligence (AI), the Internet of Things (IoT), and automation technologies.

China’s sewing machine industry has completed a strategic transformation from “cost advantage” to “technological leadership,” becoming a key partner for the transformation and upgrading of global industries such as apparel, home textiles, and automotive interiors.

II. Taizhou Cluster: Powering Global Sewing with a Seamless Supply Chain

China’s sewing machine industry has formed a complete ecosystem. This system encompasses not only sewing machine manufacturing itself but also extends to key component production, intelligent system development, and technical services.

Industrial clusters are mainly concentrated in Taizhou (Zhejiang), Shanghai, and surrounding areas, forming the world’s most complete industrial chain for sewing equipment.

According to industry statistics, Chinese manufacturers hold approximately an 85% share of the global industrial sewing machine market. Behind this figure lies continuous technological innovation and supply chain optimization.

In Taizhou, Zhejiang—a key sewing machine industry cluster—there are over 1,000 related enterprises. Everything from tiny screws to complex electronic control systems can be sourced and produced locally.

This highly integrated supply chain enables Chinese manufacturers to respond rapidly to market changes, offering high-quality products at competitive prices.

A modern sewing machine manufacturing cluster in Taizhou, Zhejiang, showing automated production lines.

China’s sewing machine manufacturing hub in Taizhou, Zhejiang, featuring advanced automated production lines.

III. Intelligent Transformation: How AI is Reshaping Traditional Sewing

The application of artificial intelligence (AI) technology is completely transforming the landscape of sewing production. Leading Chinese enterprises like Jack Sewing Machine, with their AI sewing machine Ai10, represent the cutting edge of this intelligent transformation.

Hailed as the “world’s first AI sewing machine,”the Ai10 contains a vertical model trained on over 1 million hours of sewing data. It uses sensors to recognize an operator’s hand gestures and compares them in real-time with “expert experience” within the system.

When a novice operator makes common mistakes, the system provides immediate corrective prompts, reducing traditional training cycles by over 60%. Even experienced workers can optimize their workflow through AI, boosting efficiency by 8-15%.

Another breakthrough comes from Yina Smart’s AI hanging production system. Evolving from a simple “execution system” to a predictive “management system,” it monitors production line status in real time, predicts potential bottlenecks and equipment failures, and proactively adjusts production pace and resource allocation.

This shift from “reactive” to “predictive” operation increases overall production efficiency by 20-30% while significantly reducing unplanned downtime.

IV. Commercial & Household: A Full-Scenario Product Matrix

Chinese-made sewing machines cover the complete spectrum of needs—from large-scale industrial production to household crafts—forming a differentiated product matrix.

-

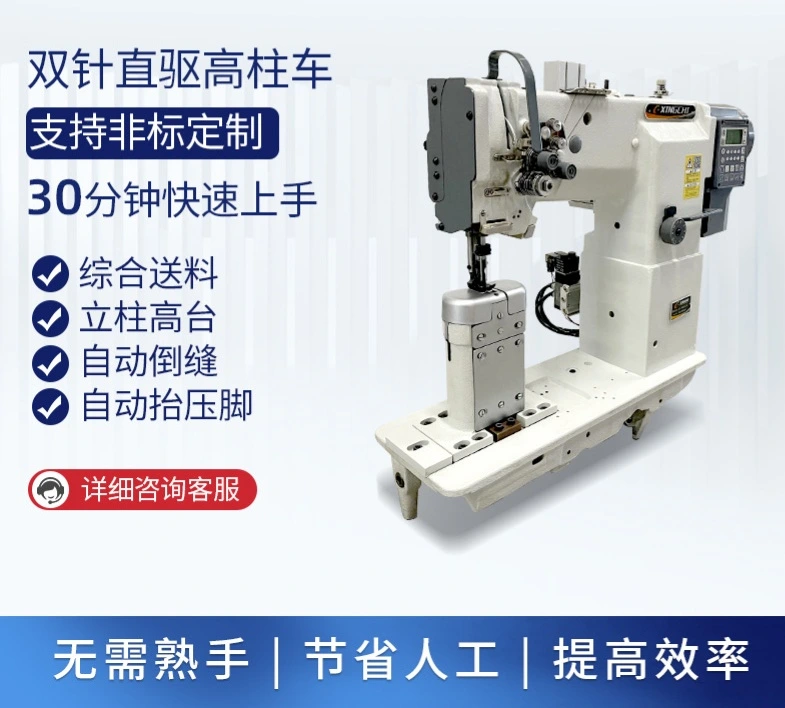

Commercial/Industrial Sewing Machines

In the industrial sector, Chinese manufacturers offer a complete series from basic lockstitch machines to highly automated intelligent units.

Intelligent lockstitch/overlock machines are equipped with high-efficiency servo motors, saving up to 60% more energy than traditional clutch motors while significantly reducing operational noise. Fully automatic pattern sewing machines complete complex pattern sewing through pre-programming, lowering skill requirements for workers and ensuring product consistency.

Specialized automatic machines, like fully automatic buttonholers and button sewers, are optimized for specific processes, offering 3-5 times the efficiency of ordinary machines. Smart sewing units integrate robots, robotic arms, and sewing machines, providing preliminary solutions to the industry challenge of automated handling of soft fabrics.

-

Household Sewing Machines

For the household market, Chinese manufacturers also offer diverse options. Multi-function electric sewing machines integrate dozens or even hundreds of stitch patterns to meet daily sewing needs. Computerized sewing-embroidery combo machines combine precise sewing with automatic embroidery functions, serving as creative tools for hobbyists.

Mini/portable sewing machines are lightweight and easy to use, ideal for minor repairs and student projects. These household models are generally user-friendly and affordable, holding a significant share in the global DIY market.

V. China’s Sewing Machine Ecosystem: The Core Clusters Driving Global Leadership

While China’s sewing machine industry spans the country, its unparalleled strength is concentrated in a few key geographic powerhouses. These core clusters, each with distinct specializations, form the world’s most complete and efficient manufacturing ecosystem for sewing technology.

Core Clusters and Their Specializations:

Taizhou, Zhejiang Province:

- The Manufacturing Heartland & Supply Chain Nexus Role:

The undisputed global epicenter and largest production base.

- Scale & Ecosystem:

With over 1,000 related enterprises, it boasts perfect vertical integration. Every component, from micro-screws to advanced electronic controls, can be sourced locally, enabling unmatched agility and cost efficiency.

- Modernization:

Rapidly transitioning to automated and smart manufacturing.

Shanghai and Surrounding Areas:

- The R&D, High-End & Global Business Hub Role:

The center for innovation, premium branding, and international operations.

- Focus:

Leads in developing computerized, automated, and intelligent sewing systems. Hosts major corporate headquarters and drives high-end market trends.

The Extended Yangtze River Delta Network:

- The Integrated Support Belt Role:

Provides critical synergy and specialized support.

- Function:

The provinces around Shanghai and Zhejiang offer a dense network for advanced components, materials, and logistics, creating a resilient “one-hour supply circle.”

VI. Top 5 Industry Leaders : Brand Power Driven by Technological Innovation

The rise of China’s sewing machine industry is powered by a group of enterprises driven by technological innovation.

-

Jack Technology Co., Ltd.

Jack Sewing Machine, a global sales leader, has set an industry technology benchmark with its Aitu brand’s AI sewing machine

-

ShangGong Group Co., Ltd.

The ShangGong Group combines technology from international brands like Germany’s Pfaff—acquired through global M&A—with Chinese manufacturing advantages.

-

Zhejiang ZOJE Sewing Technology Co., Ltd.

Zhongjie Sewing Technology focuses on the mid-to-high-end industrial market, with clear advantages in efficiency and precision for specialized machines like its fully intelligent pocket setters.

-

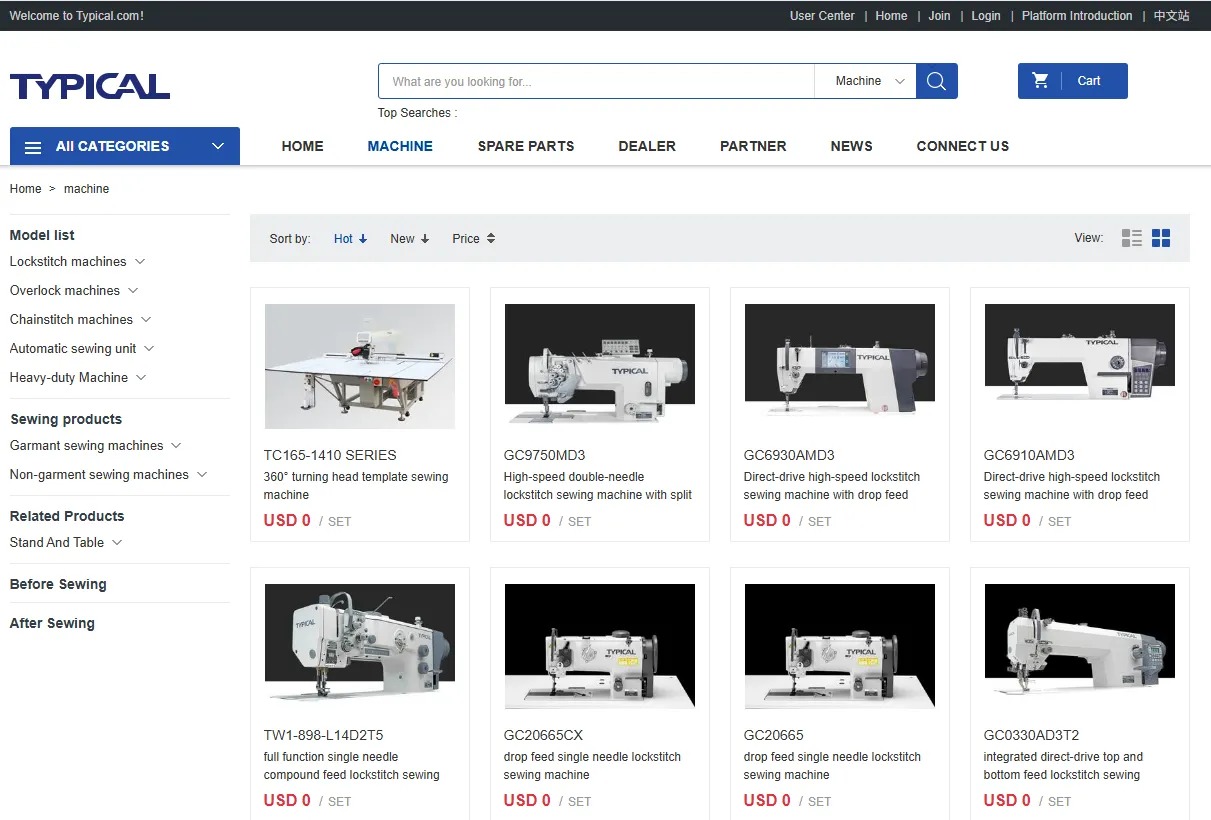

Xi’an Typical Industries Co., Ltd.

As a historic and publicly-listed enterprise in China’s sewing machinery sector, it delivers comprehensive system solutions for apparel and related industries.

-

Feiyue Group Co., Ltd.

A primary supplier of sewing equipment in China, the company combines research & development, production, and trading in its integrated business model.

These companies compete not only in product innovation but also in building global service systems. By establishing service centers and spare parts warehouses in major world markets, Chinese sewing machine manufacturers can provide timely localized support to international clients.

VII. Procurement Guide: Sourcing High-Quality Sewing Machines from China

Navigating the Chinese supply chain for industrial and commercial sewing machines requires a strategic and informed approach. Understanding the various channels available will help you find the right supplier efficiently. Here are the primary methods:

1.Direct Manufacturer Contact

This path is suitable for high-volume buyers, OEM projects, or those with highly specific technical requirements (e.g., specialized stitches for shoemaking or automotive interiors). It demands significant investment in market research, native-level language skills for technical negotiation, and robust internal resources for factory audits and quality control. Successfully navigating this channel can lead to direct pricing but carries higher due diligence risk.

2.B2B Online Platforms (Alibaba.com, Made-in-China.com)

These platforms are excellent for initial discovery, allowing you to filter hundreds of suppliers by machine type (e.g., overlock, coverstitch, bar tack), brand, and price point. You can view company certifications, request quotations, and communicate directly. Key advice: Always request authentic factory walk-through videos and detailed specification sheets, and ask for sewing samples on your specific materials to verify stitch quality and machine performance.

3.Industry Trade Shows

Attending major international trade shows remains one of the most effective ways to source. Events like CISMA (China International Sewing Machinery & Accessories Show) in Shanghai or international exhibitions like Texprocess allow you to see machines running live, compare build quality and noise levels, test user interfaces, and establish direct, trusted relationships with sales and engineering teams.

4. Engaging a Professional Sourcing Agent (Highly Recommended)

For most international buyers, partnering with a specialist like IMEXsourcing is the most efficient and low-risk strategy. We provide immense value by leveraging our local network to vet reliable factories, negotiate favorable terms, conduct rigorous pre-shipment inspections (checking motor power, stitch consistency, and safety features), and manage complex logistics and customs clearance. This single-point-of-contact service saves time, mitigates risk, and ensures you receive equipment that precisely matches your production needs.

VIII. Choose IMEXsourcing as Your Sewing Machine Sourcing Partner in China

When procuring high-quality sewing machines and complete production line equipment from China, partnering with an experienced and reliable sourcing agent is crucial. IMEXsourcing offers a comprehensive service portfolio to streamline your procurement process and ensure exceptional value, with the following core advantages:

- Extensive Industry Procurement Experience: With years of experience in sourcing garment and textile machinery, we accurately connect you with top-tier Chinese manufacturers. Our product range is comprehensive, covering everything from industrial lockstitch/overlock machines and specialized equipment (e.g., buttonholing, bartacking) to fully automated sewing units and smart production lines, as well as supporting pre-processing and finishing systems. This meets your diverse needs for different production scales, garment types, and automation levels.

- Tailored Solutions: We support in-depth customization based on your specific requirements, including equipment speed and configuration, selection of core components (such as needles, feed systems, and motors), structural adaptations for specific fabric characteristics (e.g., elasticity of knits, thickness of denim), and industrial automation system integration (such as programmable pattern sewing, automatic thread trimming, and real-time production data monitoring). This ensures the equipment perfectly matches your production volume, material properties, and final product quality standards.

- Stringent Supplier Verification: We conduct thorough factory audits of our manufacturing partners, verifying their production capacity, technical R&D capabilities, and quality control systems. We ensure suppliers hold relevant certifications (e.g., ISO 9001, CE) and that their products comply with domestic and international safety and performance standards (such as stitching precision, machine durability, energy efficiency, and operational safety).

- Professional Negotiation Capabilities: Leveraging industry resources and aggregated purchasing volume, we secure the most favorable pricing, payment terms, and after-sales service agreements for you, reducing overall procurement costs and mitigating risks.

- Full-Cycle Quality Assurance: We implement a rigorous end-to-end quality management process, including sample testing, production process monitoring, and pre-shipment inspection (focusing on key checks such as stitching quality, machine stability, durability testing, and completeness of accessories and spare parts). This ensures every delivered sewing machine and production line meets your expectations for performance and reliability.

IX.Conclusion

The future of China’s sewing machine industry is quietly unfolding in humanoid robot labs. Companies like Jack have demonstrated smart units that combine sewing robots with 3D vision-grasping technology, capable of recognizing, picking up, and sewing completely different fabrics.

These technological breakthroughs signal that global garment factories will eventually transition from labor-intensive operations to fully automated “lights-out” factories. The core technologies driving this transformation will increasingly bear the mark of “Intelligent Manufacturing in China.”