Introduction

The global home fragrance market is experiencing unprecedented growth. Fueled by the “self-care” trend, the rise in remote work, and a desire for affordable luxury, scented candles have transformed from occasional gifts into everyday essentials. For global importers, retailers, and brand owners, this presents a massive opportunity.

When it comes to turning wax and fragrance into profitable products, China remains the undisputed world leader. China is not just about low-cost production; it is the global center for innovation in wax blends, sophisticated fragrance diffusion, complex vessel manufacturing, and scalable customization. Whether you are launching a high-end boutique aromatherapy line or stocking mass-market shelves with dinner candles, Chinese manufacturers offer the capacity and versatility required.

However, sourcing candles is more complex than sourcing inert plastic goods. You are dealing with chemical compositions, fragrance loads, burn performance, and safety regulations. Finding the right supplier who balances aesthetics, olfactory performance, and compliance is crucial.

This comprehensive guide, modeled on professional sourcing practices, will walk you through everything you need to know to successfully procure scented, dinner, botanical, and specialty candles from China.

Table of Contents

I. Understanding the Diverse Landscape of Chinese Candle Products

China’s manufacturing capability covers the entire spectrum of the candle industry. Buyers must first define their niche. Below are the primary categories produced in high volume across Chinese factories.

A. Scented Container Candles (The Market Leader)

This is the largest category. Wax is poured into a vessel—usually glass, ceramic, metal tin, or concrete.

-

Key Features: High fragrance load capability; the container itself is a major design element.

-

Target Market: Home decor, gifts, aromatherapy, mass retail.

B. Dinner & Taper Candles

Traditional, long, slender candles designed for candelabras and dining settings.

-

Key Features: Usually unscented or very lightly scented so as not to interfere with food. Often made of harder paraffin or paraffin-stearin blends for structural integrity.

-

Variations: Classic tapers, spiral twists, fluted designs.

C. Tealights and Votives

Small, disposable candles in metal or plastic cups used for heating (fondue, tea warmers) or ambiance.

-

Key Features: Short burn times (3-6 hours), highly commoditized, extremely low price points per unit, often sold in bulk packs (e.g., 50-packs, 100-packs).

D. Specialty and Trending Types

-

Botanical/Inclusion Candles: Clear gel or outer wax shells embedded with dried flowers, herbs, or fruits. Requires high manufacturing skill to ensure safety (preventing inclusions from catching fire).

-

Essential Oil/Aromatherapy Candles: Focus on natural wellness. Must use 100% natural essential oils rather than synthetic fragrance oils. Often paired with soy or beeswax.

-

Odor-Eliminating Candles: Formulated with specific enzyme-based or neutralizing fragrances designed to combat pet, smoke, or kitchen odors, rather than just masking them.

-

Sand Wax / Granulated Wax: A DIY trend where loose, scented wax granules are poured into a container with a separate wick inserted by the end-user.

II. The Core: Materials and Their Advantages

The perceived quality and price point of a candle are determined almost entirely by the materials used. Chinese manufacturers are adept at blending different waxes to achieve desired price-performance ratios.

Wax Types

| Wax Material | Description & Advantages | Disadvantages | Ideal Application |

| Paraffin Wax | A byproduct of petroleum refining. The traditional standard. Excellent “scent throw” (both cold and hot). Very stable and inexpensive. | Derived from fossil fuels; can produce more soot if wicks are not trimmed; perceived negatively by eco-conscious consumers. | Mass-market scented candles, taper candles, tealights. |

| Soy Wax | Vegetable wax made from soybean oil. The undisputed king of the current market. Biodegradable, renewable, burns cleaner and slower than paraffin. | Softer than paraffin; can struggle with very high fragrance loads; sometimes “frosts” (white crystalline look) over time. | Mid-to-high-end container candles, eco-friendly brands. |

| Beeswax | 100% natural wax produced by honeybees. Emits a natural honey scent; burns very clean with a bright flame. | The most expensive option; natural scent can clash with added fragrances; difficult to color. | Luxury, ultra-natural, or religious candles. |

| Coconut Wax | A premium vegetable wax. Extremely creamy appearance and holds scent very well. | Expensive and very soft (low melting point), so it is almost always blended with soy or harder waxes. | High-end luxury container candles. |

| Wax Blends | The Industry Standard. Most commonly a Paraffin/Soy blend. | Blends allow manufacturers to combine the scent throw and stability of paraffin with the marketing appeal and creaminess of soy. | Requires transparency with consumers if claiming “natural.” |

Wicks and Fragrances

-

Cotton Wicks: The standard. Look for lead-free, 100% cotton, sometimes with a paper core for rigidity.

-

Wood Wicks: Trendy due to the crackling sound they make when burning. They require specific wax formulations to stay lit reliably.

-

Fragrance Oils: The soul of the candle. Chinese factories source fragrances globally (Givaudan, IFF, Symrise) and locally.

-

Crucial Metric: Fragrance Load. This is the percentage of fragrance oil to wax. A cheap candle might have 3-5%. A luxury candle might have 8-12%.

-

III. Key Specifications and Parameters for Buyers

When communicating with suppliers, vague requests lead to poor samples. You must specify:

-

Wax Weight vs. Total Weight: Don’t just say “a 300g candle.” Clarify if that is 300g of wax fill or the total weight including the heavy glass jar.

-

Burn Time: Measured in hours. This is heavily influenced by wax type, wick size, and jar diameter.

-

Fragrance Load Percentage: Specify your required level (e.g., “We require an 8% fragrance load”).

-

Container Finish: Clear glass, frosted, matte sprayed color, electroplated (metallic look), ceramic glazing.

-

Secondary Packaging: Gift box quality (thickness of cardboard), internal inserts to prevent breakage.

IV. China’s Candle Manufacturing Industrial Clusters

Like many industries in China, candle manufacturing is clustered geographically. Knowing these hubs helps locate the right type of supplier.

A. Qingdao & Yantai (Shandong Province)

The Hub for Glass & Volume.

Shandong is massive in glassware production. Consequently, many of China’s largest candle fillers are located here to be close to the container source.

-

Best For: Large volume orders of glass container candles, mid-range retail brands, and major supermarket suppliers.

B. Dongguan, Shenzhen & Guangzhou (Guangdong Province)

The Hub for Design, Luxury & Exports.

Factories here are highly export-oriented, accustomed to Western quality standards, and skilled in complex designs, premium packaging, and working with high-end fragrance houses.

-

Best For: Boutique brands, luxury gift candles, complex OEM/ODM projects requiring unique molds or sophisticated scents.

C. Yiwu & Jinhua (Zhejiang Province)

C. Yiwu & Jinhua (Zhejiang Province)

The Hub for Commodities & Budget Items.

Famous for small commodities. Factories here excel at high-speed production of low-cost items.

-

Best For: Tealights, basic votives, party candles, and budget-tier container candles where price is the primary driver.

V. Top Chinese Candle Manufacturers

Disclaimer: The status of manufacturers changes. Buyers should always conduct current due diligence. The following are historically significant, large-scale players representative of the industry’s capabilities.

-

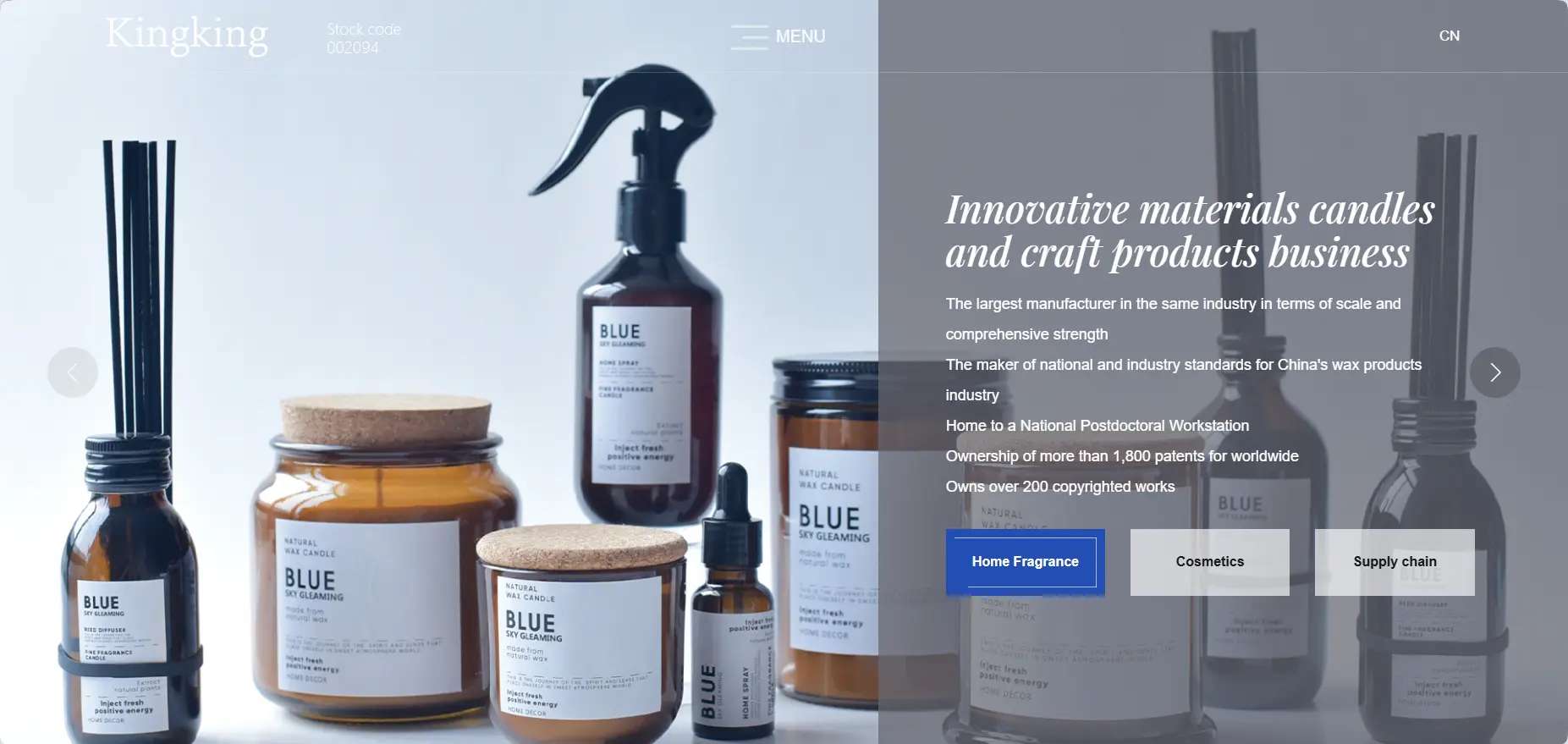

Qingdao Kingking Applied Chemistry Co., Ltd.

-

Location: Qingdao, Shandong. https://www.chinakingking.com/en/

-

Profile: One of the largest candle manufacturers globally, and perhaps the biggest in Asia. They supply major global retailers like Walmart, IKEA, and Target. They have massive R&D facilities and enormous production capacity for glass candles and diffusers.

-

Strength: High volume, standardized quality, reliable supply chain.

-

-

Talent Fareast Candle Co., Ltd.

-

Location: various, main in North China. http://www.talentfareast.com

-

Profile: Another industry giant with a long history of exporting to Europe and North America. They cover the full spectrum from basic tealights to high-end decorative candles.

-

Strength: Diverse product range and deep experience in regulatory compliance for Western markets.

-

-

Dalian Talent Gift Co., Ltd.

-

Location: Dalian, Liaoning (North China). https://www.daliantalent.com

-

Profile: Known for high-quality production and artistic designs. They often focus on mid-to-high-end market segments and have strong design capabilities for seasonal gifts (Christmas, Halloween).

-

Strength: Design-led manufacturing and quality finishes.

-

-

Zhejiang Shaoxing Wonders Artware Co., Ltd.

-

Location: Shaoxing, Zhejiang. https://www.wax-wonders.com

-

Profile: A strong player in the Zhejiang cluster, often focusing on cost-effective production of tealights, pillars, and basic container candles.

-

Strength: Competitive pricing and high output for commodity items.

-

-

Xiamen Apple Aroma Co., Ltd. (and similar Fujian/Guangdong based firms)

-

Location: Xiamen, Fujian. http://applearoma.com/about.asp

-

Profile: These types of companies often focus heavily on the “aroma” aspect, specializing in diffusers, essential oil candles, and design-centric home fragrance products.

-

Strength: Focus on scent trends, modern aesthetics, and ODM services for boutique brands.

-

-

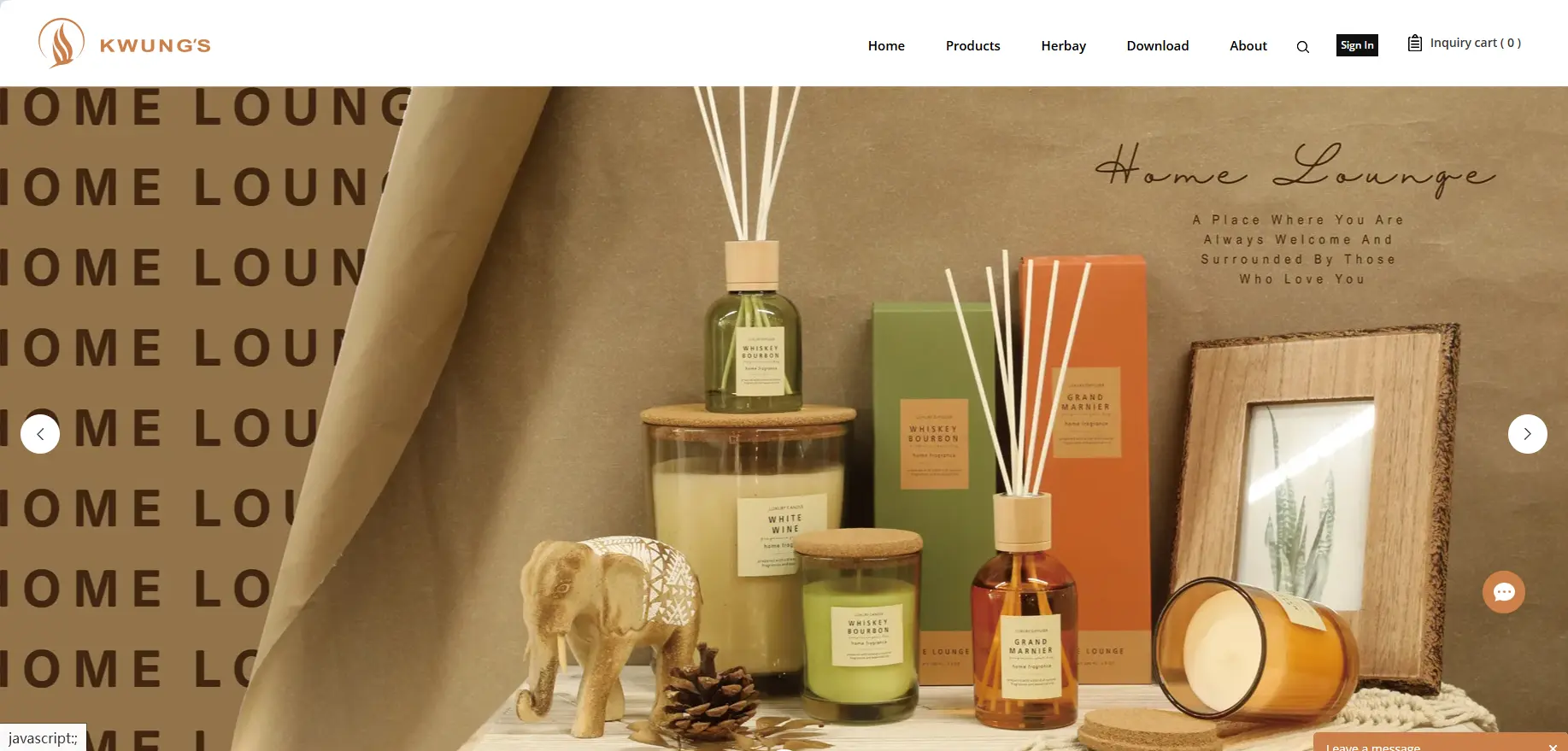

Ningbo Kwung’s Wisdom Art & Design Co., Ltd.

-

Location: Ningbo, Zhejiang. https://showroom.kwungs.com

-

Profile: A prominent Chinese orginal design manufacturer and supplier of aromatic candles, reed fragrance diffusers and other home fragrance and decoration products with a glorious history of over 20 years.

-

Strength: Has 300,000 products, fashionable and exquisite designs, various shapes and styles, rich and colorful scents.

-

IV. Navigating Certifications and Compliance

Candles involve fire and inhaled chemicals; compliance is non-negotiable. You must ensure your imported products meet the standards of your target market.

Safety & Performance Standards (Crucial for EU/US)

-

EN 15493 (European Standard): Specifications for fire safety of candles. It dictates maximum flame height, stability so it doesn’t tip over, and self-extinguishing properties at the end of the wax life.

-

EN 15426 (European Standard): Specifications for sooting behavior. It limits how much black smoke a candle can emit.

-

ASTM F-Standards (USA): The US equivalents for fire safety and labeling (e.g., ASTM F2058 for caution labeling).

Chemical & Material Compliance

-

REACH (Europe): A massive regulation concerning chemicals. You must ensure the wax, fragrance, and wick do not contain Substances of Very High Concern (SVHC) above permitted limits.

-

TSCA (USA): Toxic Substances Control Act compliance for chemical substances.

-

SDS / MSDS (Safety Data Sheets): Your supplier must be able to provide an SDS for the fragrance oil mixture used. This is essential for shipping logistics and customs clearance.

VII. Essential Sourcing Considerations: A Buyer’s Checklist

Sourcing candles has unique pitfalls. Here is how to avoid them.

A. The “Cold Throw” vs. “Hot Throw” Test

Do not judge a sample just by smelling it out of the box.

-

Cold Throw: The scent strength when the candle is unlit. Important for retail shelf appeal.

-

Hot Throw: The scent strength when burning. This is what generates repeat customers. A cheap candle may smell strong initially but have zero throw when lit. Always burn-test samples.

B. Wick Testing and “Tunneling”

If the wick is too small for the container diameter, the wax will not melt to the edges. It will burn straight down the middle, leaving wasted wax on the sides. This is called “tunneling” and is a sign of a poorly engineered candle. Ensure the factory matches the wick size correctly to your chosen jar.

C. The MOQ (Minimum Order Quantity) Challenge

Candles are heavy and low-value-per-cubic-meter, making full container loads (FCL) the most economical shipping method.

-

The Issue: Factories need high MOQs to make a custom fragrance run worth it (often 1,000–3,000 pieces per scent).

-

Strategy for Startups: To lower MOQs, ask the factory for their “stock fragrance list.” Using scents they already have in production for other clients can significantly lower the minimum buy required.

D. Packaging is Paramount (Preventing Breakage)

Most scented candles are in glass. Shipping a container of glass across the ocean requires robust packaging.

-

Requirement: Demanded drop-tested packaging. Specify inner cartons (e.g., 6 candles per inner box) separated by sturdy cardboard dividers, inside a master carton. Do not accept bulk-packed glass candles without individual separators.

E. Seasonal Timing

The candle industry is highly seasonal, peaking in Q3 for Christmas production. If you want orders delivered by September/October, you must finalize samples and place orders by April/May.

VIII. Choose IMEXsourcing as Your Scented Candle Sourcing Partner in China

When procuring high-quality scented candles, home fragrance products, and specialty wax items from China, partnering with an experienced and reliable sourcing agent is crucial given the complexities of fragrance formulations, wax properties, and safety regulations. IMEXsourcing offers a comprehensive service portfolio to streamline your procurement process and ensure exceptional value, with the following core advantages:

Extensive Industry Procurement Experience: With years of experience in sourcing home fragrance and decor products, we accurately connect you with top-tier Chinese manufacturers. Our product range is comprehensive, covering everything from luxury scented container candles (glass, ceramic, metal tins) and aromatherapy essential oil candles to eco-friendly plant-based wax options (soy, coconut, palm blends), traditional dinner tapers, pressed tealights, and functional odor-eliminating candles. This meets your diverse needs for different market tiers, scent profiles, and aesthetic designs.

Tailored Solutions: We support in-depth customization based on your specific requirements, including precise fragrance load percentages for optimal scent throw, selection of specific wax blends to achieve desired burn characteristics, and choice of wick materials (such as lead-free cotton or crackling wood). We also facilitate bespoke container design (custom colors, finishes like electroplating or frosting, and unique lid materials) and intricate secondary packaging solutions to ensure the final product perfectly matches your brand image, target market price point, and quality standards.

Stringent Supplier Verification: We conduct thorough factory audits of our manufacturing partners, verifying their production capacity, fragrance blending expertise, laboratory testing capabilities, and quality control systems. We ensure suppliers hold relevant business certifications (e.g., ISO 9001) and that their raw materials and final products comply with domestic and international safety and performance standards (such as IFRA compliance for fragrance oils, ASTM F/EN fire safety and container integrity standards, and necessary REACH/CLP documentation for international shipping).

Professional Negotiation Capabilities: Leveraging strong industry relationships and aggregated purchasing volume, we secure the most favorable pricing and contract terms for you, which is particularly helpful in managing the complex Minimum Order Quantities (MOQs) often required by fragrance houses. We aim to reduce procurement costs while avoiding potential hidden risks such as the use of inferior wax fillers, diluted fragrances, or delivery delays caused by seasonal production congestion.

Full-Cycle Quality Assurance: We implement a rigorous end-to-end quality management process, starting with critical pre-production sample evaluation (verifying both “cold throw” and “hot throw” scent performance). We continue with production process monitoring (checking crucial parameters like wax pouring temperatures) and conclude with detailed pre-shipment inspection. Our final checks focus on visual aesthetics (ensuring no defects like tunneling, wet spots, or frosting), wick centering accuracy, adherence to specified burn times, and the robustness of master carton packaging to prevent melting or breakage during ocean transit. This ensures stable and reliable quality for every delivered shipment

IX. Conclusion

Sourcing candles from China offers an incredible spectrum of possibilities, from budget-friendly tealights in Yiwu to luxurious, complex-scented soy candles in Dongguan. The key to success lies in moving beyond a generic request for “candles.” By specifying your wax blend, demanding rigorous burn testing, understanding the regional specializations, and ensuring strict safety compliance, you can leverage China’s manufacturing might to build a successful and profitable home fragrance brand.